Custom CNC Turning Services

High-precision CNC turning solutions for prototypes and production parts that demand consistent accuracy, smooth surface finishes, and stable dimensional performance. Our multi-axis turning centers deliver reliable results across metals and engineering plastics, supported by ISO-certified quality processes and fast global turnaround.

- Todos os carregamentos são seguros e confidenciais

Iniciar um novo orçamento CNC

ISO 9001:2015 | AS9100D | ISO 13485 | Conformidade com ITAR

O Yicenprecision Instant Quoting Engine está coberto pelas Patentes U.S. Nos. 11,086,292, 11,347,201, 11,693,388, 11,698,623, 12,099,341, e 12,189,361. Outras patentes pendentes.

What Is CNC Turning?

CNC turning is a precision machining process used to create accurate cylindrical and concentric components by removing material from rotating stock. The controlled toolpaths deliver stable diameters, clean surface finishes, and consistent dimensional repeatability for both prototypes and production parts.

How CNC Lathes Operate

A spindle rotates the raw material while cutting tools shape external and internal features such as profiles, bores, grooves, and threads. This method ensures stable geometry and predictable accuracy.

Turning Configurations

Different types of lathes handle different levels of work, from basic turning of round parts to advanced machines that produce very small or complex shapes. Each type helps improve stability, tool control, and accuracy during machining.

Turning Workflow

The machine executes programmed feeds, speeds, and tool motions to achieve precise dimensions.

Maximum CNC Turning Capabilities

Our CNC turning capabilities are engineered for consistent accuracy, smooth finishes, and efficient production cycles across metal and plastic components. Each setup supports reliable machining for both prototypes and large-batch manufacturing.

A fresagem CNC é uma técnica de maquinagem subtractiva que envolve o corte de material metálico e plástico sob a forma de formas precisas e repetíveis utilizando máquinas de 3, 4 e 5 eixos. Mais adequada para geometrias complicadas, tolerâncias rigorosas e acabamentos de superfície elevados em protótipos e componentes de produção.

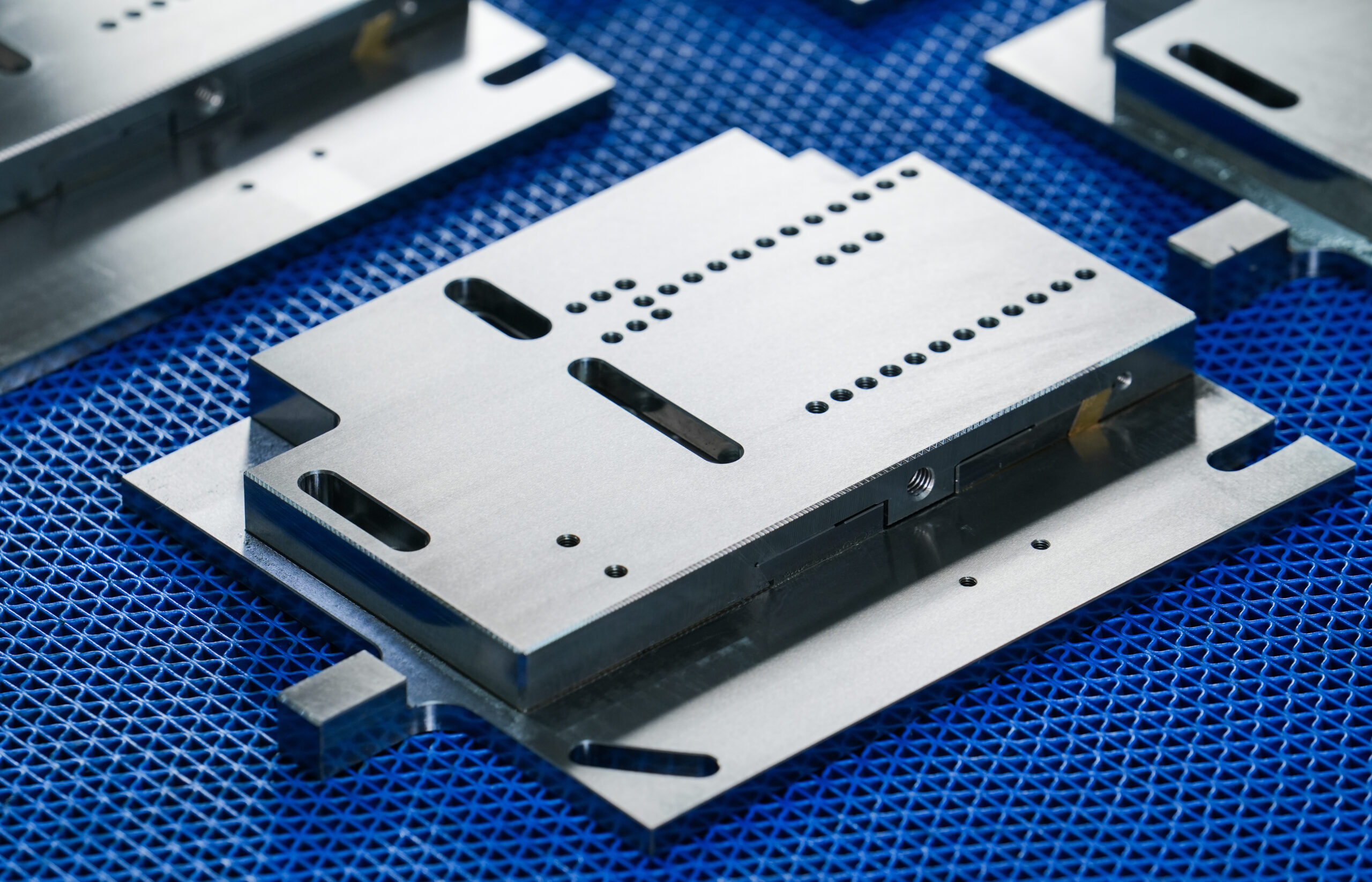

We provide precision CNC machining services for custom parts in metals and engineering plastics. From prototypes to production runs, every component is machined to tight tolerances with consistent, repeatable accuracy.

Concebemos e fabricamos gabaritos e dispositivos de precisão que melhoram os processos de maquinagem, montagem e inspeção. Os nossos dispositivos são fabricados através de operações CNC de alta precisão para serem estáveis, repetíveis e duradouros em pequenos lotes e em grandes volumes de fabrico.

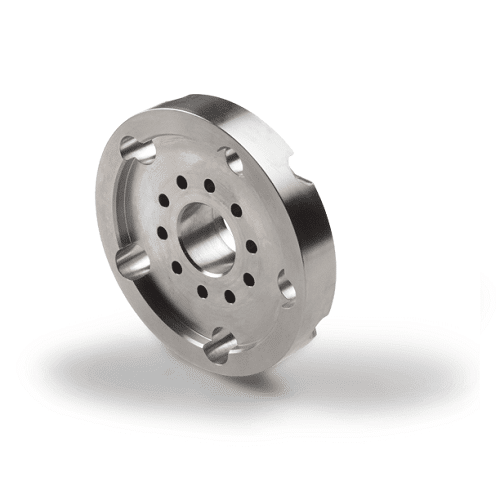

CNC Turned Parts for Precision Components

Descubra os nossos especialistas precision cnc turning servicesonde a precisão encontra o desempenho em todas as fases. Desde protótipos complexos a componentes prontos a produzir, os nossos custom cnc turning services fornecer peças de alta precisão. Cada corte, cada contorno, trabalhado com uma qualidade excecional, consistência e atenção aos detalhes.

Materials for CNC Turning

Engenheiros e fabricantes líderes confiam na Yicen Precision para iterações rápidas e peças duráveis e de alto desempenho. Quer se trate de protótipos ou de produção em grande escala, a nossa vasta seleção de materiais garante precisão, resistência e fiabilidade para qualquer projeto de maquinagem CNC.

Alumínio

Alumínio 5052

Aluminum 7075 & 7075-T6

Aluminum 6063-T5

Aluminum 7050-T7451

Aluminum MIC-6

Aluminum 6061-T6

Aluminum 2024-T3

Bronze/Brass

Brass C360

Brass 260

C932 M07 Bearing Bronze

Cobre

H59

H60

Plásticos

ABS

Acetal [Delrin]

Acrylic, G-10 Garolite

Nylon 6/6

PEEK

Policarbonato

PTFE [Teflon]

Polypropylene

Ultra-High Molecular Weight Polyethylene

Steel

Alloy Steel 4130

Alloy Steel 4140

ASTM A36

Stainless Steel 15-5

Stainless Steel 17-4

Stainless Steel 18-8

Stainless Steel 303

Stainless Steel 304

Stainless Steel 316/316L

Stainless Steel 416

Stainless Steel 420

Steel 1018

Steel A36

Titânio

Titanium Grade 2

Titanium 6Al-4V

Zinc

Zinc Sheet Alloy 500

Tolerâncias de torneamento CNC

Our turning centers support a wide range of diameters, lengths, and feature types, ensuring reliable machining for small precision components and larger rotational parts.

| Funcionamento | Diâmetro máximo | Comprimento máximo |

|---|---|---|

| Torneamento standard | Ø300 mm | 500 mm |

| Live Tooling | Ø250 mm | 400 mm |

| Swiss-Type Turning | Ø32 mm | 150 mm |

Surface Finishing for CNC Turning

Precision-turned parts benefit from specialized surface treatments that enhance strength, durability, and overall performance. These treatments are ideal for optimizing the functionality of shafts, bushings, and cylindrical components.

A opção mais rápida e mais económica, deixando marcas de ferramentas visíveis e arestas ou rebarbas potencialmente afiadas. A rugosidade da superfície é de aproximadamente 125 µin Ra, e as rebarbas podem ser removidas mediante pedido.

Um revestimento espesso de crómio que aumenta a dureza, a resistência ao desgaste e a durabilidade. Perfeito para peças sujeitas a grandes esforços, como veios e pistões.

Uma fina camada de níquel galvanizado que melhora a resistência ao desgaste e à corrosão. Proporciona um acabamento brilhante e atrativo para peças funcionais.

Um tratamento químico que cria uma superfície escura e preta mate nas peças de aço. Oferece uma ligeira resistência à corrosão e reduz o reflexo da luz.

Um acabamento liso e brilhante obtido por polimento mecânico. Ideal para peças decorativas que exijam um brilho melhorado e uma rugosidade reduzida.

Uma textura linear e acetinada criada com cintas abrasivas ou escovas. Reduz as pequenas imperfeições e oferece um aspeto limpo e decorativo.

Precisa de um acabamento específico? Envie um pedido de cotação e nós trabalharemos consigo para encontrar uma solução à medida do seu projeto.

Cria um acabamento liso e mate através de jato de areia, normalmente com esferas de vidro, oferecendo uma estética melhorada e uma textura de superfície uniforme.

Key Features of CNC Turning

Our CNC turning capabilities are engineered for consistent accuracy, smooth finishes, and efficient production cycles across metal and plastic components. Each setup supports reliable machining for both prototypes and large-batch manufacturing.

| Heading | Descrição |

|---|---|

| High Dimensional Accuracy | Stable spindle control and rigid toolpaths maintain tight diameter, roundness, and concentricity requirements. |

| Smooth Surface Finishes | Rotational cutting produces clean surfaces ideal for sealing fits, sliding interfaces, and precision assemblies. |

| Efficient for Cylindrical Geometries | Cost-effective machining for shafts, bushings, pins, connectors, and other rotational components. |

| Fast Setup & Short Lead Times | Turning centers allow quick tool changes and reduced cycle time, supporting rapid prototyping and scaling. |

| Live Tooling Support | Add milled flats, threads, grooves, slots, or cross-holes in a single setup for better accuracy and lower cost. |

| Stable Repeatability for Production | Rigid fixturing and automated toolpath control deliver consistent part geometry across long production runs. |

CNC Turning Design Guidelines

Effective design choices help reduce machining time, improve accuracy, and maintain stable part geometry during turning.

| Parâmetro | Especificação | Why It Matters |

| Raios internos | Avoid sharp corners; recommended radius: 2.6 × tool diameter. | Prevents tool vibration and ensures stability in deep pockets. |

| Roscas e furos roscados | Depth = 3× Ø (small) or 4× Ø (larger threads). | Prevents tool breakage and ensures strong thread engagement. |

| Espessura mínima da parede | Metals: 0.3–1.0 mm / Plastics: 1.2–1.5 mm. | Prevents vibration, deflection, and machining marks. |

| Tamanhos e profundidade dos furos | Min diameter: 0.50 mm / Max depth: 4× diameter. | Ensures reliable chip evacuation and precision bore accuracy. |

| Cortes inferiores | Supports square, full radius, and dovetail profiles. | Using standard profiles reduces machining time and cost. |

| Texto e gravação | Min width: 0.6 mm / Min depth: 0.1 mm. | For turned parts, laser engraving is preferred for finer marking. |

| Evitar o excesso de restrições | Design for stable surfaces and supported geometries. | Reduces the need for excessive fixturing and complexity. |

| DFM Review | Engineering check for manufacturability and tool access. | Ensures high-quality output and efficient production cycles. |

Capacidades de garantia de qualidade e inspeção

Cada peça torneada é inspeccionada utilizando fluxos de trabalho de metrologia certificados para garantir a precisão dimensional, a integridade da superfície e o desempenho repetível em todos os volumes de produção.

Precisão dimensional

Inspeção CMM para pontos de referência críticos, diâmetros, circularidade e concentricidade

Medidores de furos, micrómetros e sistemas de altura para verificações rápidas durante o processo

Suporta caraterísticas de tolerância apertada até ±0,001 pol. (±0,025 mm)

GD&T e verificação de tolerâncias

Controlo da rugosidade da superfície (Ra 3,2 μm standard; Ra 0,8 μm opcional)

Medição de runout e concentricidade para componentes rotativos

Conformidade com as normas de acabamento específicas do torneamento

Ensaios de superfície e acabamento

Inspeção em conformidade com a norma ISO 2768-mK e ASME Y14.5

Verificação do perfil, posição, perpendicularidade, paralelismo, circularidade

Garante a estabilidade geométrica em condições reais de maquinagem

Rastreabilidade e relatórios

Relatórios FAI, certificados de materiais (MTR) e dados CMM disponíveis

Rastreio de lotes para requisitos aeroespaciais, médicos e industriais

Manutenção segura de registos para uma pista de auditoria completa e conformidade de qualidade

Indústrias que servimos

A Yicen Precision serve um vasto espetro de indústrias, abrangendo a indústria aeroespacial, automóvel, eletrónica, médica e muito mais. Somos especializados no fornecimento de peças fiáveis e de alta qualidade, concebidas para responder aos desafios de engenharia únicos de cada indústria.

Applications of CNC Turning

CNC turning is ideal for precision rotational components where concentricity, smooth surface finishes, and consistent dimensional control are critical.

Shafts & Axles

For motors, gear assemblies, automation systems, and drive mechanisms where straightness, runout, and load-bearing interfaces matter.

Bushings & Spacers

High-accuracy cylindrical components for reducing friction, maintaining alignment, and supporting rotational motion.

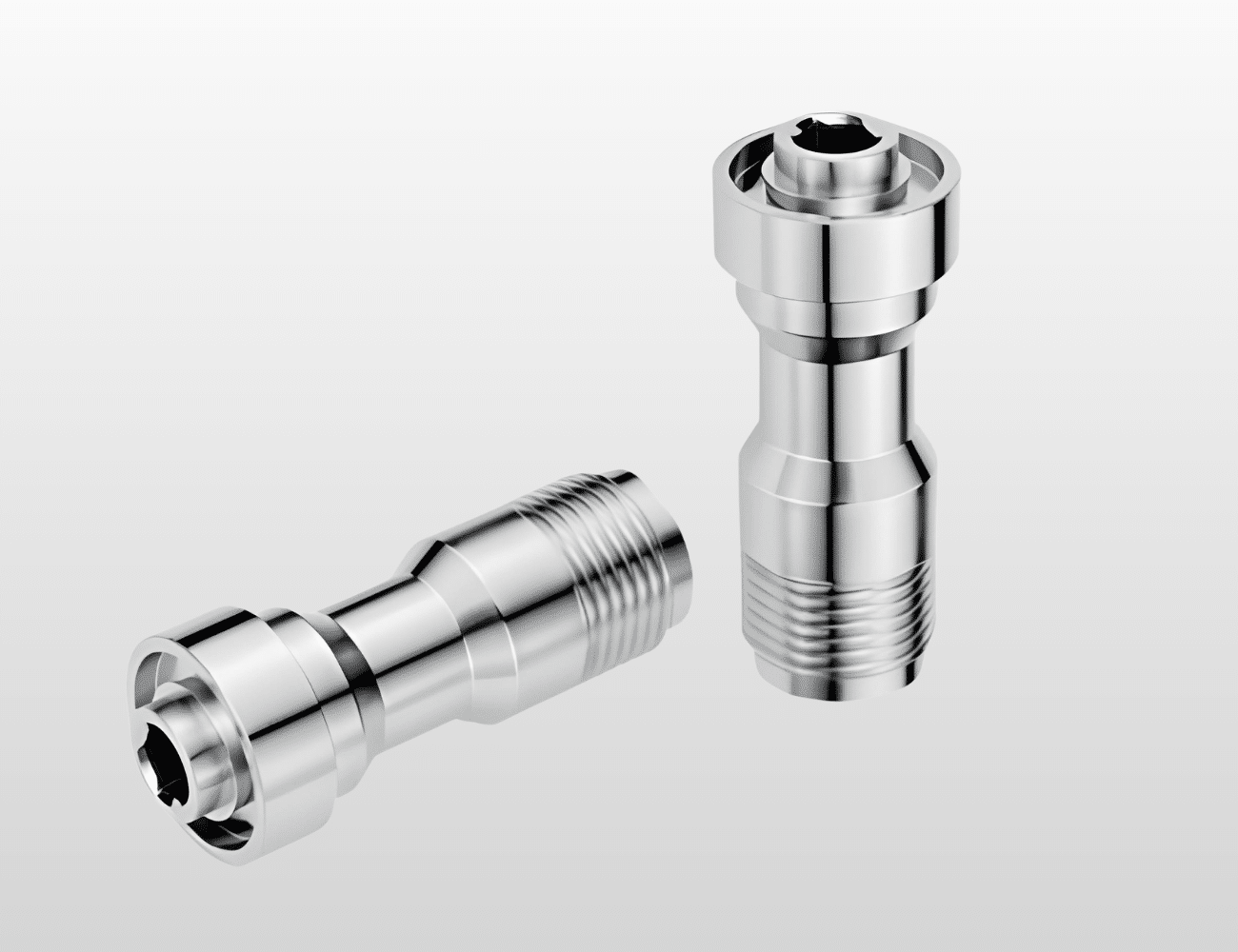

Threaded Connectors & Fittings

Precision internal/external threads for hydraulic, pneumatic, and mechanical systems; supports ISO/ASME thread standards.

Pins, Dowels & Couplers

Used for alignment, load transfer, and joining mechanisms in automotive, aerospace, and machinery assemblies.

Sleeves, Housings & Collars

Turned enclosures and structural rings requiring tight diametrical tolerances and smooth surface profiles.

Hydraulic & Pneumatic Components

Valves, adapters, and pressure-line components requiring concentric sealing surfaces and controlled tolerances.

Custom Rotational Components

Specialized geometries, stepped profiles, and multi-diameter parts for prototypes, tooling, and production assemblies.

Why Choose Yicen Precision to CNC Turning ?

We deliver reliable, production-ready turned parts with consistent accuracy, fast lead times, and engineering support built around real manufacturing requirements.

Micron-Level Precision

Stable, repeatable accuracy down to ±0.001″ for rotational components requiring controlled runout and concentricity.

Advanced Multi-Axis Turning Centers

Live tooling, Swiss-type, and multi-axis equipment allow complex features, reduced setups, and better dimensional consistency.

Support for Manufacturability

Our team reviews geometry, material selection, tolerances, and thread standards to ensure optimal machining and lower cost.

ISO-Certified Quality Systems

ISO-Certified Quality Every part passes through controlled inspection workflows aligned with ISO 9001:2015, AS9100D, and ISO 13485 standards.

Reliable Global Delivery

Secure logistics, protective packaging, and validated workflows ensure parts arrive on time and within specification.

Fast Prototyping & Scalable Production

From rapid prototypes to high-volume production runs, we maintain stable lead times with predictable output.

Soluções de maquinagem Yicen

Quer esteja a criar um pequeno lote de peças personalizadas ou a aumentar para uma produção de grande volume, os serviços de maquinação da Yicen oferecem a flexibilidade de que necessita.

A maquinação rápida de protótipos CNC é perfeita para criar protótipos de engenharia ou de produção que se assemelham muito ao produto final, tanto no aspeto como na funcionalidade. Na Yicen, oferecemos orçamentos imediatos e entrega rápida, fornecendo-lhe protótipos maquinados CNC precisos e de alta qualidade para as suas necessidades.

- Prazo de execução: 1-5 dias úteis

- Capacidade: 1-100 unidades

- Obter 20% de desconto no preço

A maquinagem CNC de baixo volume funciona frequentemente como uma ponte entre a prototipagem e a produção em massa para produções novas e emergentes. Com a Yicen, este processo torna-se mais fácil, mais eficiente e económico, permitindo-lhe escalar a produção rapidamente, mantendo os padrões de alta qualidade.

- Prazo de execução: 5-15 dias úteis

- Capacidade: 101-10.000 unidades

- Cumprir especificações rigorosas

A maquinagem de produção CNC é a melhor solução para produzir mil peças ou mais de forma eficiente. Tirando partido de uma seleção diversificada de materiais e de capacidades de automação e multieixos, a Yicen oferece uma produção de grande volume com tolerâncias apertadas, precisão dimensional superior, elevada fiabilidade e tempos de execução rápidos.

- Prazo de execução: 2-4 semanas

- Capacidade: Mais de 10.001 unidades

- Qualidade consistente

Perguntas mais frequentes

Torneamento CNC

What file formats do you accept?

We accept all standard CAD and engineering formats used in CNC machining:

- STEP (.step / .stp)

- IGES (.igs / .iges)

- Parasolid (.x_t / .x_b)

- SolidWorks (.sldprt)

- DXF / DWG for 2D drawings

- PDF for dimensioned technical drawings

Providing a technical drawing with GD&T improves accuracy, especially for parts needing precision CNC turning.

What materials can be turned?

We machine a wide range of metals and engineering plastics commonly used in precision CNC turning. Metals include aluminum (6061, 7075), stainless steel (304, 316, 17-4), carbon steels, brass, copper, titanium, and high-temperature alloys such as Inconel. Plastics such as POM, Nylon, PEEK, PTFE, PVC, and ABS are also supported for custom CNC turned parts. Material selection is validated based on machinability, dimensional stability, and final application requirements.

What tolerances can you achieve?

Typical CNC turning tolerances are ±0.005″, while tight-tolerance CNC turning services can achieve ±0.001″ or better on critical diameters, shoulders, and mating surfaces. Roundness can be controlled to ≤ 0.002″, with concentricity typically held within ≤ 0.005″ depending on geometry and tool access. All tolerance requirements are confirmed during DFM review to ensure the design is manufacturable.

Do you offer live tooling?

Yes. Our CNC turning services include live tooling and multi-axis turning, enabling milling, drilling, slotting, and threading operations within a single setup. This improves concentricity, reduces tool changes, minimizes fixture requirements, and shortens lead time — especially for complex turned-milled components.

What surface finishes do you offer?

We provide a full range of finishing options for metal and plastic turned parts:

- As-turned

- Bead blasting

- Revestimento em pó

- Anodizing (Type II / Type III)

- Polishing / Electropolishing

- Óxido preto

- Zinc & nickel plating

Finishes are selected based on durability, corrosion resistance, friction behavior, or cosmetic needs. Surface roughness can reach Ra 0.8 μm for high-precision turning applications.

Transformar conceitos em peças de precisão

Somos especialistas em converter as suas ideias em componentes funcionais de alta qualidade, com uma velocidade e precisão sem paralelo. Com tecnologia avançada e perícia artesanal, criamos peças que cumprem as especificações mais complexas.

- Engenharia de precisão de ponta a ponta

- Fluxos de trabalho de produção simplificados

- Compromisso com a excelência da maquinagem

- Entrega fiável e atempada

- Todos os carregamentos são seguros e confidenciais