When it comes to high-quality manufacturing, how a part looks and performs after machining is just as important as its dimensions. Surface finishing is the final step that transforms a raw machined part into a polished, functional, and aesthetically pleasing product. At Yicen Machining, we offer a full range of surface finishing techniques to meet the technical, visual, and environmental requirements of every industry.

Whether you need corrosion resistance, improved wear properties, or a sleek appearance, we tailor the perfect finish for your parts.

Why Surface Finishing Matters

Surface finishing improves more than just looks. It directly affects:

- Durability

Enhanced protection against corrosion, friction, and wear.

- Functionality

Improved adhesion, sealing, or fit in assemblies.

- Cleanliness & Hygiene

Critical for medical or food-related applications.

- Aesthetics

Clean, polished, or textured finishes for product presentation and branding.

Let’s explore the key surface finishing processes Yicen Machining offers to give your parts the edge they need.

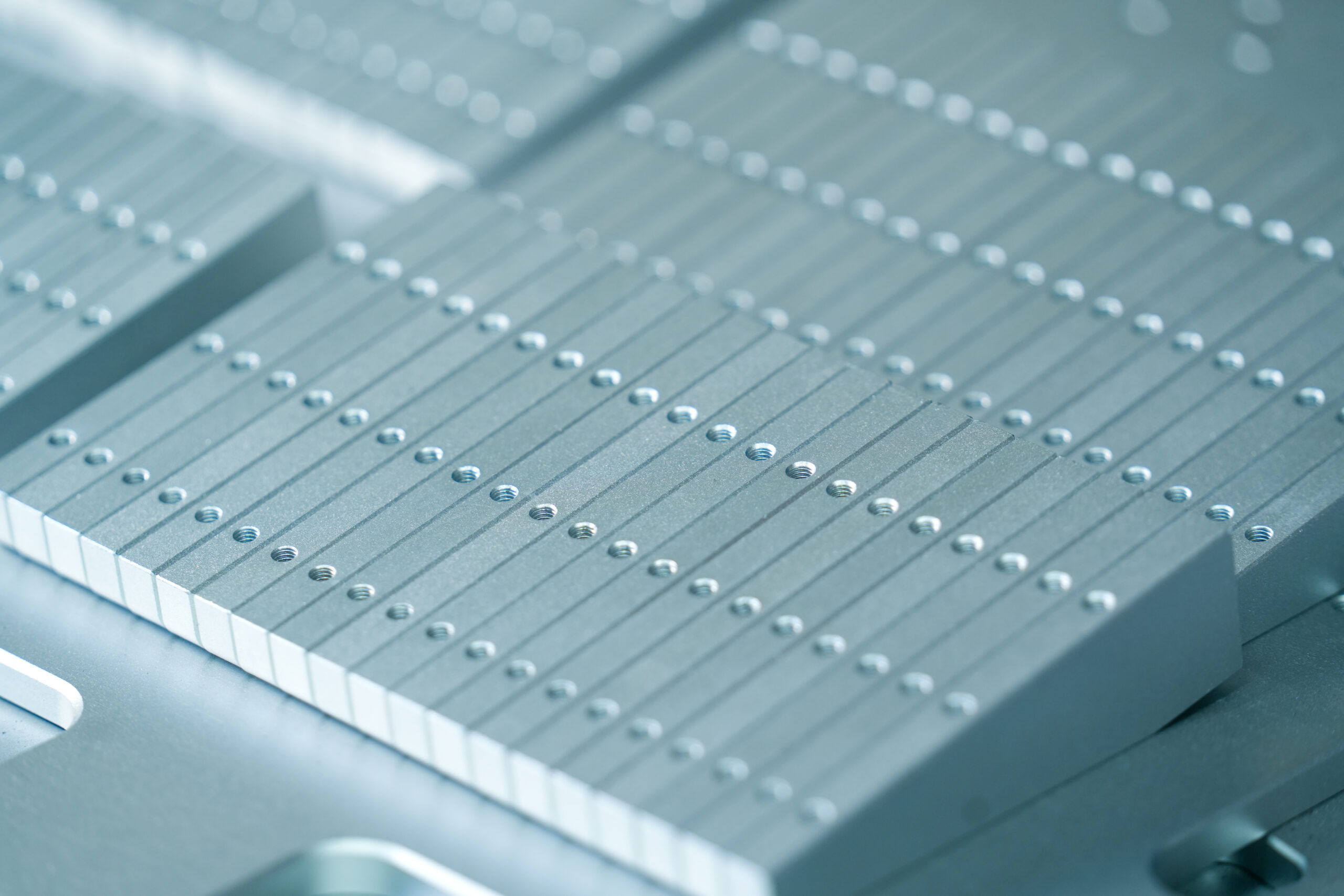

1. Anodizing

Best for: Aluminum parts requiring corrosion resistance and color options.

Anodizing creates a controlled oxide layer on aluminum surfaces, making them more durable and resistant to wear and oxidation. It also allows for vibrant color finishes.

- Type I (chromic), Type II (decorative), Type III (hardcoat) options

- Available in clear, black, red, blue, gold, and custom shades

- Ideal for aerospace, electronics, and consumer products

2. Powder Coating

Best for: Strong, durable, and decorative coatings on metal surfaces.

Powder coating uses electrostatically charged powder that is cured under heat to create a hard, smooth finish. It’s more environmentally friendly than wet paint and highly durable.

- Wide range of colors and textures

- Scratch, UV, and chemical resistant

- Great for enclosures, frames, and outdoor parts

3. Bead Blasting

Best for: Uniform matte surface finish and texture preparation.

Bead blasting uses fine glass beads propelled at high pressure to create a smooth, satin finish without damaging the base material.

- Removes surface imperfections and machine marks

- Ideal for cosmetic parts

- Commonly used on aluminum and stainless steel

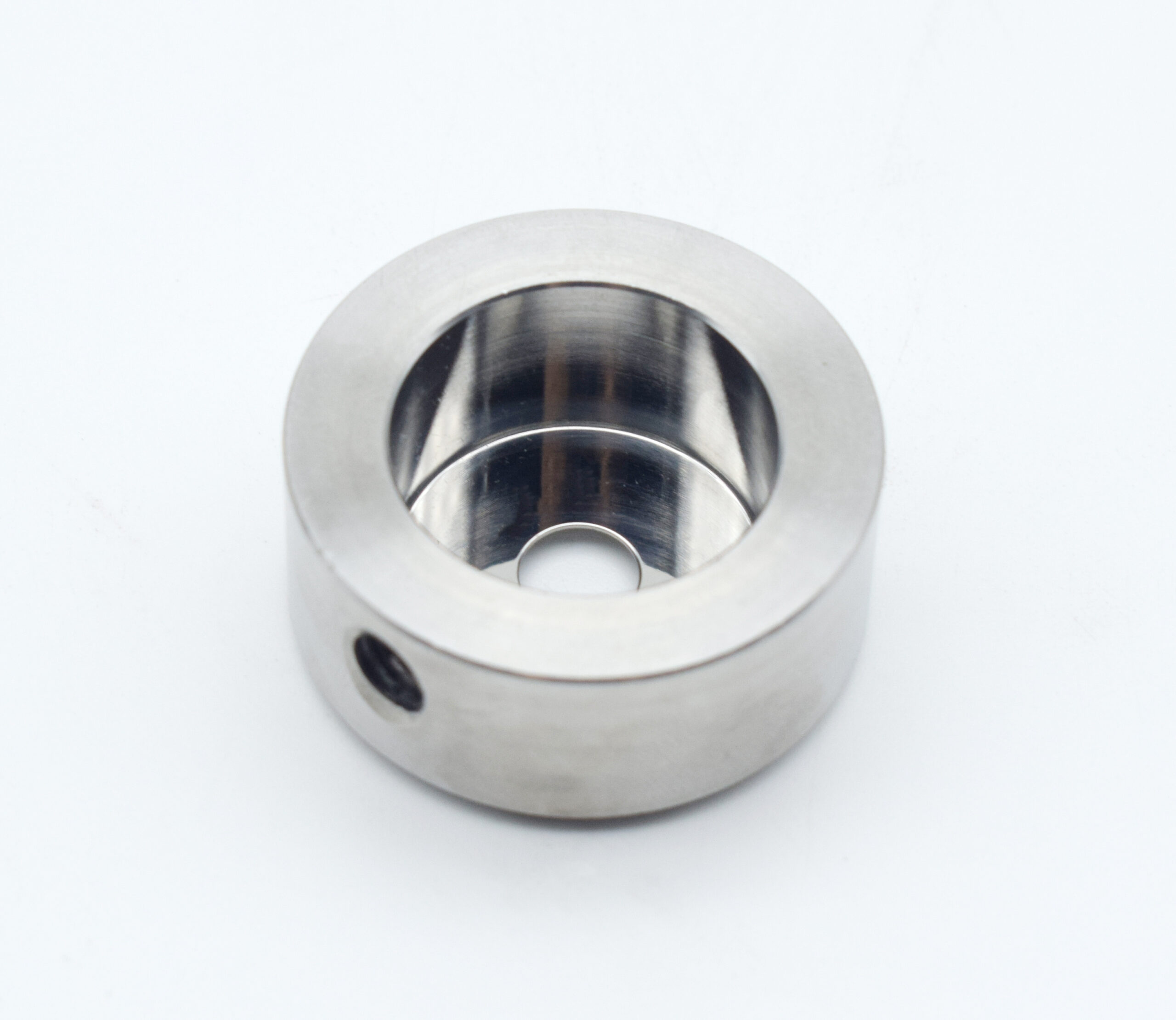

4. Electropolishing

Best for: Ultra-smooth, shiny finish on stainless steel and metal parts.

Electropolishing removes a thin layer of metal using an electrolytic process, reducing surface roughness and improving corrosion resistance.

- Ideal for medical and food-grade components

- Creates a sterile, clean surface

- Enhances fatigue strength and part lifespan

5. Brushing

Best for: Directional texture and a professional appearance.

Brushed finishes are created using abrasive belts or pads to give a uniform linear texture. Often used when aesthetics and grip are equally important.

- Common on stainless steel, aluminum, and brass

- Industrial and consumer-grade applications

- Easy to clean and maintain

6. Black Oxide Coating

Best for: Mild corrosion resistance and minimal dimensional impact.

Black oxide is a chemical conversion coating used mainly on steel and stainless steel. It provides a dark, matte finish and reduces glare.

- Does not significantly alter dimensions

- Economical corrosion protection

- Common in tools, fasteners, and automotive parts

7. Chromate Conversion Coating

Best for: Lightweight corrosion protection with paint or adhesive bonding.

Also known as Alodine, this process is used primarily on aluminum to enhance corrosion resistance and improve paint adhesion.

- Mil-DTL-5541 compliant for aerospace

- Available in clear or yellow finishes

- Preserves electrical conductivity

8. Vapor Smoothing for 3D Printed Parts

Best for: Smoothing the surface of 3D printed thermoplastics.

Vapor smoothing exposes parts to a controlled chemical vapor that melts the outer surface slightly, creating a glassy-smooth, sealed finish.

- Great for improving surface feel and sealing porous parts

- Typically used on ABS, ASA, and similar polymers

- Functional and aesthetic upgrade for printed components

9. Custom Finishing Options

At Yicen Machining, we also offer custom surface treatments based on your project’s unique requirements:

- Laser engraving for logos or part numbers

- Painting for brand colors and custom aesthetics

- Tumbling for edge softening and surface refinement

- Polishing for mirror-like finishes on metals or plastics

Choosing the Right Finish

The ideal surface finish depends on several factors:

- Material type

- End-use environment (corrosive, high-temperature, etc.)

- Aesthetic requirements

- Mechanical performance goals

Our team helps you select the right finish to balance function, durability, and cost.

Request a quote today and let Yicen Machining finish your parts with precision and professionalism.