As-plated, it ranges from 45–60 HRC. After heat treatment, hardness can reach up to 68 HRC, comparable to hard chrome.

Electroless nickel plating offers a corrosion-resistant coating without the need for electricity to enhance surface smoothness Contact Yicen Machining today for high-performance surface protection.

| Description | General Tolerance or Standard |

|---|---|

| Surface Roughness (Ra) | 0.2 – 1.0 µm |

| Compatible Materials | Steel, aluminum, copper |

| Dimensional Tolerance Impact | ±0.005 – ±0.015 mm due to coating thickness |

| Visual Appearance | Uniform, metallic coating |

| Mechanical Properties | Enhanced wear and corrosion resistance |

| Best Applications | Aerospace, automotive, electronics |

We specialize in converting your ideas into high-quality, functional components with unparalleled speed and accuracy. With advanced technology and expert craftsmanship, we create parts that meet the most complex specifications.

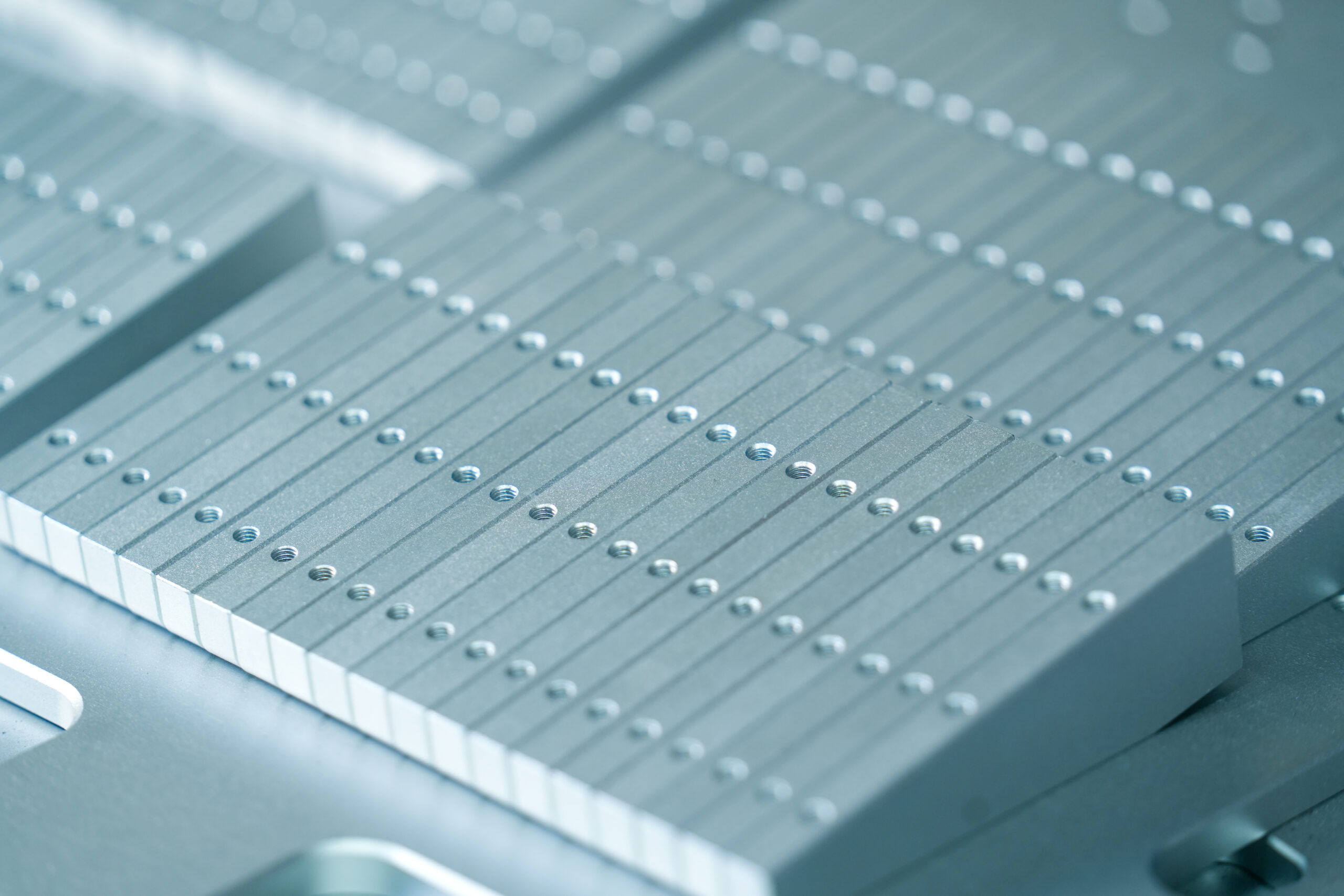

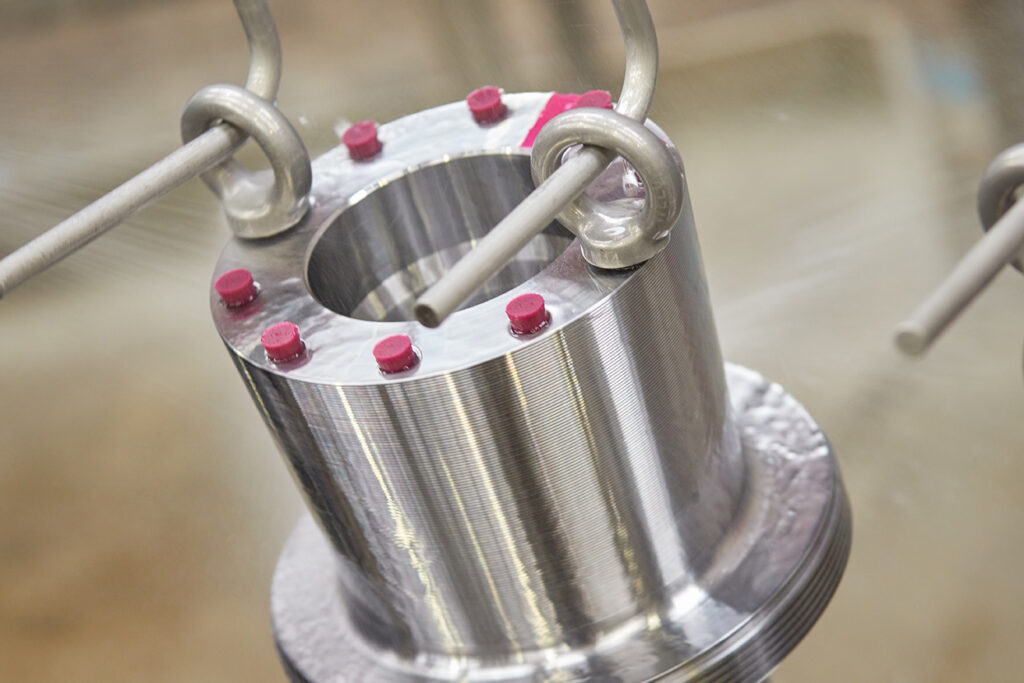

Electroless nickel plating (ENP) is a reliable surface finishing solution for demanding applications where consistent coating, corrosion protection, and improved hardness are essential. At Yicen Machining, we apply ENP to parts with complex geometries and tight tolerances ensuring a durable, uniform finish without the use of electricity.

Whether your components operate in aerospace, oil & gas, automotive, or electronics environments, our electroless nickel plating ensures maximum wear resistance, dimensional control, and part longevity.

Yicen Machining recommends ENP for high-performance parts where precision and protection are essential. Key benefits include:

Electroless nickel plating works on a variety of substrates, including:

Yicen Machining ensures material compatibility and selects the right phosphorus content based on your operational requirements.

At Yicen Machining, we offer comprehensive ENP services with expert process control, technical support, and fast lead times:

Electroless nickel plating provides superior protection and performance across industries. At Yicen Machining, we ensure your parts are finished to the highest standards ready to perform in even the most challenging environments.

Request a quote today and see how our ENP services can elevate the durability and precision of your components.

Explore Machining services blog for expert insights on CNC machining, industry trends, manufacturing tips, and technology updates—designed to keep you informed, inspired, and ahead in precision engineering.

What is the hardness of the coating?

As-plated, it ranges from 45–60 HRC. After heat treatment, hardness can reach up to 68 HRC, comparable to hard chrome.

Is ENP electrically conductive?

Yes. It maintains conductivity and is used in electronics for its solderability and corrosion resistance.

Can it coat internal features like holes and threads?

Absolutely. ENP is known for its uniform coverage, including complex geometries and internal cavities.

Does ENP prevent rust?

Yes. Especially high-phosphorus ENP offers excellent corrosion resistance, even in marine or chemical exposure.

How thick is an electroless nickel coating?

Typical coating thickness ranges from 5 to 50 microns (0.0002″ to 0.002″), depending on the protection required.