Our wood, plastics, and metals are processed by expert CNC routing.

O nosso CNC Routing Services deliver high-precision machining for a wide range of materials, including metals, plastics, and composites. We handle large sheets with fast turnaround times, achieving tolerances as tight as ±0.001” (±0.025mm). Serving industries like automotive, aerospace, and signage, we ensure top-quality results backed by ISO 9001:2015 and AS9100D certifications. Request a quote or upload your CAD file today to get started.

ISO 9001:2015 | AS9100D | ISO 13485 | Conformidade com ITAR

O Yicenprecision Instant Quoting Engine está coberto pelas Patentes U.S. Nos. 11,086,292, 11,347,201, 11,693,388, 11,698,623, 12,099,341, e 12,189,361. Outras patentes pendentes.

| Capability | Standard Tolerance | Precision / High-End | Factors Affecting Accuracy |

| Linear Dimensions | ±0.127 mm (0.005″) | ±0.05 mm (0.002″) | Thermal Expansion, Machine Calibration, Material Hardness |

| Hole Diameters | ±0.05 mm (0.002″) | ±0.025 mm (0.001″) | Tool Wear, Spindle Runout, Chip Clearance |

| Edge Finish (Ra) | 3.2 – 6.3 µm | < 1.6 µm | Feed Rate, Cutting Speed, Tool Sharpness |

| Positional Accuracy | ±0.10 mm (0.004″) | ±0.05 mm (0.002″) | Gantry Alignment, Lead Screw Pitch, Drive System Backlash |

| Angular Accuracy | ±0.5° | ±0.1° | Squareness of Axes, Fixture Stability, Part Orientation |

At Yicen Precision, we offer a wide range of materials to suit your CNC routing needs, ensuring the highest precision and durability for your parts. Whether you’re working with metals or plastics, we provide expertly crafted solutions to meet your project’s specific requirements. Explore the materials we work with and find the perfect match for your next project.

| Material | Descrição | Opções de acabamento | Aplicações |

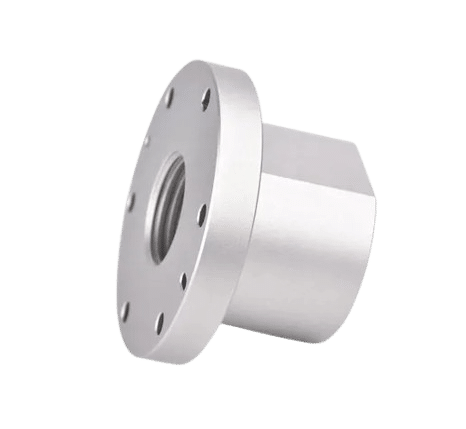

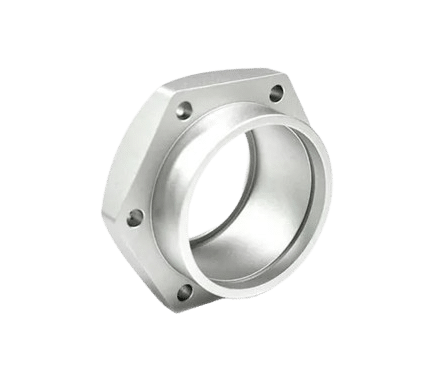

| Aluminum 6061 | Structural Strength, Weldable | Anodizing, Powder Coating | Construction, Automotive |

| Aluminum 7075 | High Strength, Durable | Anodização, polimento | Aerospace, Military |

| Aluminum 2024 | Fatigue Resistant, Lightweight | Cladding, Painting | Aircraft Frames, Structures |

| Alumínio 5052 | Marine Grade, Formable | Anodizing, Painting | Marine Tanks, Sheet Metal |

| Aluminum 5083 | Chemical Resistant, Tough | Anodização, polimento | Industrial Gear, Marine |

| Material | Descrição | Opções de acabamento | Aplicações |

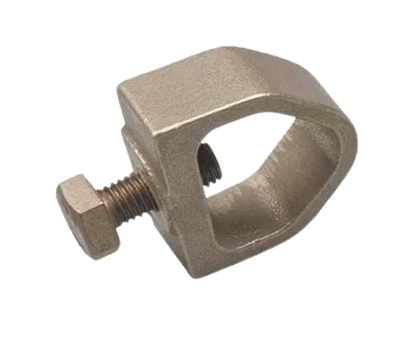

| Brass C360 | Low Friction, Machinable | Brushing, Polishing | Decorative Hardware, Gears |

| Brass C464 | Corrosion Resistant, Strong | Polishing, Lacquering | Naval Fittings, Fasteners |

| Brass C260 | Highly Ductile, Formable | Brushing, Lacquering | Electrical Parts, Cartridges |

| Material | Descrição | Opções de acabamento | Aplicações |

| Copper C101 | High Thermal Conductivity | Polishing, Plating | Heat Sinks, Electronics |

| Cobre C110 | High Electrical Conductivity | Plating, Passivation | Busbars, Electrical Wiring |

| Material | Descrição | Opções de acabamento | Aplicações |

| Cast Acrylic | Superior Optical Clarity | Flame Polishing | Signage, Luxury Displays |

| Extruded Acrylic | High Impact Resistance | Machine Polishing | Guards, Window Glazing |

| Material | Descrição | Opções de acabamento | Aplicações |

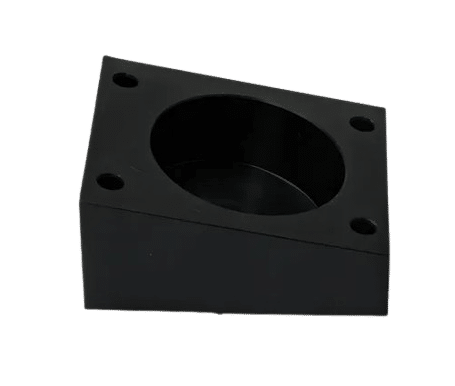

| General Purpose ABS | Rigid, Impact Strong | Painting, Sanding | Protective Enclosures |

| Flame Retardant ABS | Heat Resistant | Textured Coating | Electronic Housings |

| Material | Descrição | Opções de acabamento | Aplicações |

| GP Polycarbonate | Virtually Unbreakable | Vapor Polishing | Machine Shields |

| Optical Grade PC | High Light Transmission | Buffing, Polishing | Face Shields, Lenses |

| Material | Descrição | Opções de acabamento | Aplicações |

| High Density PE | Chemical Resistant | Edge Trimming | Chemical Tanks |

| Food Grade HDPE | Moisture Resistant | Machining | Cutting Boards |

| Material | Descrição | Opções de acabamento | Aplicações |

| UHMW-PE | Ultra-Low Friction | Precision Cutting | Wear Strips, Guides |

| Material | Descrição | Opções de acabamento | Aplicações |

| Rigid PVC | High Stiffness | Solvent Welding | Industrial Piping |

| Flexible PVC | Corrosion Resistant | Machining | Gaskets, Seals |

| Material | Descrição | Opções de acabamento | Aplicações |

| Nylon 6 (Cast) | Wear Resistant | Annealing, Polishing | Heavy Duty Gears |

| Nylon 66 (Extruded) | Low Friction | Precision Machining | Bushings, Bearings |

| Material | Descrição | Opções de acabamento | Aplicações |

| PETG Sheet | Food Safe, Strong | Die Cutting | Medical Packaging |

| PET (Polyester) | High Dimensional Stability | Polimento | Precision Components |

For precise and cost-effective CNC routing, follow key design guidelines like optimizing tool diameter, minimizing thin walls, and ensuring proper fixturing. These tips help streamline production, reduce waste, and improve part quality, making your projects faster and more efficient.

| Guideline | Especificação |

| File Preparation | Use vector files (DXF/SVG) with closed paths for clean CNC Routing results. |

| Orientação da peça | Align parts to maximize material yield and simplify the CNC Routing path. |

| Minimum Inside Radius | Maintain a 0.125″ (3.2mm) radius for smooth and stable CNC Routing cuts. |

| Tool Diameter Limits | Keep tool diameter under 1/3 material thickness for accurate CNC Routing precision. |

| Minimize Thin Walls | Maintain at least 1/4″ (6mm) wall thickness to prevent vibration during routing. |

| Nesting Clearance | Leave at least one tool diameter space between nested parts for structural integrity. |

| Kerf & Compensation | Factor tool radius into designs for accurate dimensions and CNC Routing cuts. |

| Fixturing & Tabs | Use tabs to stabilize parts; ensure secure fixturing for CNC Routing. |

| Avoid Over-Constraining | Simplify part geometry to ensure stable and cost-effective CNC Routing setup. |

Em Precisão Yicen, we offer a variety of CNC routing surface finishes designed to meet the aesthetic and functional needs of your parts. Whether you need a smooth, polished finish or added protective coatings, we have the right option for your project.

Rough finish is ideal with bigger bits and higher feed rates and results in a more textured surface.

Fine bits will also produce a smooth finish when the speed is lower to reduce roughness in order to produce a clean surface that is polished.

Routine sanding of tools after routing creates a more homogeneous look and finishes wood and plastic, which is preferable.

The finish type can be matte finishes which are produced by slowing cutting speed or particular tooling to produce a slight non-reflective surface.

The Bead blasting involves the use of abrasives such as sand or glass beads to produce a plain, rough surface on the metals and plastics.

Polishing is a finishing process of coating a surface, especially an acrylic, metal, and plastic surface, with finer abrasives to give it a mirror-like polish.

Flame polishing is mainly applied to acrylic and plastics in which heat is used to flatten and give the surface a gloss to eliminate tool marks.

Depending on the process, the anodizing process improves corrosion resistance and gives aluminum a matte or a glossy finish.

Em Precisão Yicen, we ensure every CNC machined part meets the highest quality standards through a rigorous inspection process. Our team conducts comprehensive checks throughout the manufacturing cycle to guarantee dimensional accuracy and surface finish, ensuring your parts meet your specifications.

Using advanced CMM and digital measurement systems, we ensure every part meets tight tolerances with precision at the micron level.

Thorough visual checks ensure that every part is free from defects, scratches, and other visual imperfections.

Each batch of parts undergoes strict quality verification to ensure consistency and performance across high-volume runs.

We provide detailed material certificates, FAI reports, and CMM data sheets for full transparency and traceability.

Our expert precision CNC services deliver high-performance results at every stage. From intricate prototypes to production-ready components, we provide custom high-accuracy parts crafted with exceptional quality and consistency. Every cut and contour is designed with strict attention to detail to meet your project’s exact needs.

Para começar, carregue facilmente os seus ficheiros CAD através da nossa plataforma online segura.

Escolha o material, o acabamento, as tolerâncias e o prazo de entrega preferido para corresponder às necessidades do seu projeto.

Receba um orçamento em tempo real com base no seu desenho e nas especificações selecionadas, sem atrasos.

As suas peças são fabricadas por parceiros de confiança, verificadas quanto à qualidade e entregues à sua porta atempadamente.

Em Precisão Yicen, we offer unmatched CNC routing capabilities for projects of any size. Here’s why you should choose us:

We specialize in handling large-format sheets for precise, high-quality cuts.

Our team works with a wide range of materials, including metals, plastics, and composites, to meet your exact requirements.

We deliver high-precision parts, achieving tolerances as tight as ±0.001” (±0.025mm).

Get your parts quickly without compromising on quality, ensuring timely delivery for your project.

Our experts provide ongoing support throughout the design and manufacturing process to ensure optimal results.

We optimize your designs to reduce material waste and production time, providing cost-efficient solutions without sacrificing quality.

A Yicen Precision serve um vasto espetro de indústrias, abrangendo a indústria aeroespacial, automóvel, eletrónica, médica e muito mais. Somos especializados no fornecimento de peças fiáveis e de alta qualidade, concebidas para responder aos desafios de engenharia únicos de cada indústria.

Vantagens

Aplicações

Somos especialistas em converter as suas ideias em componentes funcionais de alta qualidade, com uma velocidade e precisão sem paralelo. Com tecnologia avançada e perícia artesanal, criamos peças que cumprem as especificações mais complexas.

CNC routing offers versatility, but there are other cutting methods like laser cutting, waterjet, and CNC milling. Each has its strengths and is suited to different project needs. This comparison helps you choose the right process based on precision, speed, and material.

| Caraterística | Roteamento CNC | Corte a laser | Corte por jato de água | Fresagem CNC |

| Custo das ferramentas | Low (No tooling required) | Moderate (Laser setup) | Moderate to High (Abrasive used) | High (Requires specialized tools) |

| Prazo de execução | 1-3 Days | 1-5 Days | 3-5 Days | 3-7 Days |

| Part Quantity | Small to large volume | Small to medium volume | Medium to large volume | Medium to high volume |

| Tolerância | ±0.001″ to ±0.005″ (High precision) | ±0,001″ a ±0,005″ | ±0,005″ a ±0,010″ | ±0.0005″ to ±0.005″ |

| Material Options | Wood, plastics, composites, metals | Thin metals, plastics | Metals, stone, glass, composites | Metals, plastics, composites |

| Complex Geometry | Excellent for 2D, 2.5D, and complex cuts | Limited to 2D cuts | Handles 2D and complex cuts | Ideal for 3D shapes, detailed milling |

| Acabamento da superfície | Clean edges with post-processing | Smooth finish, minimal post-processing | Rough edges, no post-processing | Smooth finish with minimal post-processing |

| Velocidade | Moderate (Dependent on material) | Fast (For thin materials) | Slow (Due to water pressure) | Moderate to high depending on part size |

| When Not Recommended | Not ideal for very fine details | Not suitable for thick or hard materials | Not recommended for small or delicate parts | Not ideal for intricate 2D designs or thin materials |

Which materials do you work with CNC Routing?

Our wood, plastics, and metals are processed by expert CNC routing.

What would be the accuracy of your professional CNC Routing Service?

Our CNC Routing Service has an accuracy of the range of 0.127mm.

Are you providing prototyping CNC Routing Services?

Yes, our CNC Routing Services specializes in high-speed custom prototyping.

Do you handle large size sheets for CNC Routing project?

Yes,We handle large-size sheets with our general-purpose services.

What is so special about Yicen that you would choose them to your CNC Routing Services?

Yicen offers quality, cost-effective, and efficient CNC Routing Services to its customers on a daily basis.