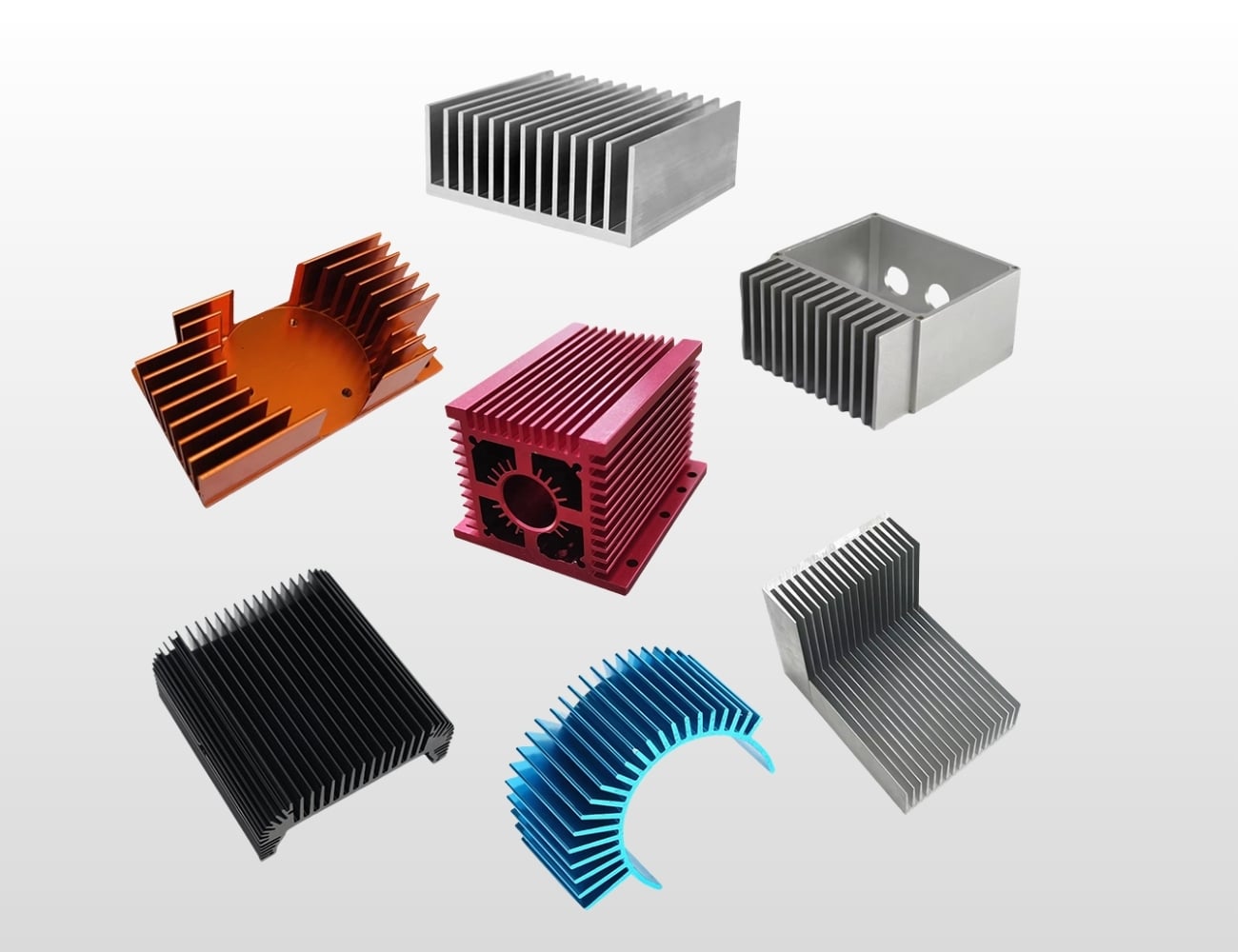

A. What are Cooling Systems and Heat Sinks?

Cooling systems and heat sinks are precision-engineered thermal management components designed to absorb, conduct, and dissipate heat generated by electronic components during operation. These thermal solutions include passive heat sinks with extended fin surfaces, active cooling assemblies with integrated fan mounts, vapor chamber heat spreaders, liquid cooling plates, and hybrid thermal management systems. They are critical in laptops, desktop computers, gaming consoles, smartphones, tablets, VR headsets, networking equipment, and high-performance audio amplifiers.

The primary function of cooling systems and heat sinks is transferring heat away from sensitive electronic components to prevent thermal throttling, system instability, and premature component failure. They maintain optimal operating temperatures, extend device lifespan, enable sustained high-performance operation, and ensure user safety by preventing excessive surface temperatures. Effective thermal management directly impacts processing speed, battery efficiency, acoustic performance, and overall user experience in modern consumer electronics.

B. Principais requisitos técnicos

Manufacturing cooling systems and heat sinks demands precise attention to thermal and mechanical specifications. Dimensional tolerances for base plate flatness typically range from 0.001″ to 0.003″ across the thermal interface surface to ensure maximum contact with heat-generating components and minimize thermal resistance. Fin spacing tolerances of ±0.010″ maintain optimal airflow characteristics and heat dissipation efficiency.

Material specifications prioritize thermal conductivity, with aluminum alloys offering 150-200 W/m·K and copper providing 350-400 W/m·K for maximum heat transfer. Surface finish requirements on thermal interface surfaces demand Ra values below 32 microinches to minimize air gaps and improve thermal coupling with processors or other components. For anodized finishes, coating thickness must be controlled to maintain dimensional tolerances while providing corrosion resistance and improved emissivity.

Fin geometry specifications include precise height control within ±0.020″, consistent thickness throughout the fin array, and smooth surfaces to minimize airflow resistance. For active cooling systems, mounting provisions for fans require precise hole positioning within ±0.005″ and perpendicularity within 0.003″ to ensure proper fan alignment and vibration control. Thermal performance requirements often specify minimum heat dissipation rates measured in watts per degree Celsius, validated through thermal testing and computational fluid dynamics analysis.

Weight optimization is critical for mobile devices, requiring thin-wall machining capabilities while maintaining structural integrity under thermal cycling and mechanical stress. Assembly features including mounting holes, thermal paste channels, and retention clip interfaces demand precise positioning and dimensional control for reliable installation.

C. Desafios e soluções para o fabrico

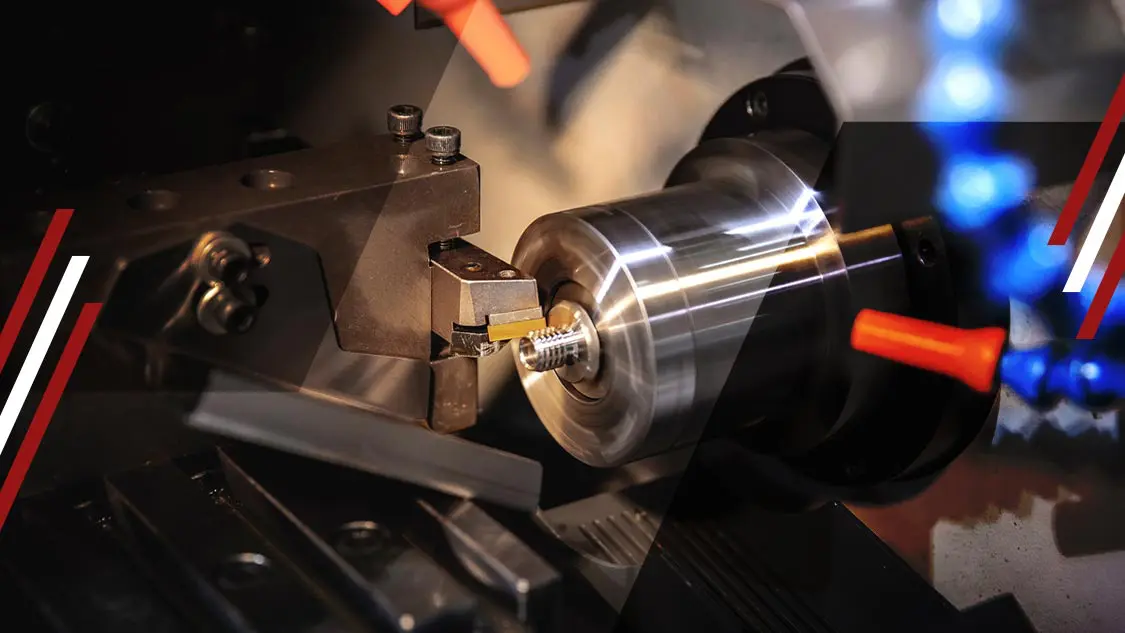

Machining cooling systems and heat sinks presents significant challenges including producing thin, closely-spaced fins without breakage or distortion, achieving mirror-smooth base plate surfaces for optimal thermal contact, and maintaining dimensional stability in large surface area components susceptible to thermal expansion during machining. High-aspect-ratio fins are vulnerable to deflection and chatter, while aluminum’s tendency to produce built-up edge can compromise surface finish. Complex internal cooling channels in liquid cooling plates require specialized tooling access.

Yicen Precision addresses these challenges through advanced machining strategies specifically developed for thermal management components. Our high-speed 5-axis CNC machining centers equipped with specialized tooling produce intricate fin arrays using optimized cutting parameters that minimize deflection forces. Climb milling strategies and sharp cutting tools prevent material tearing and ensure clean fin edges. For dense fin arrays, we employ thin-kerf cutters and strategic tool path planning that reduces cutting forces while maintaining productivity.

Base plate surface finishing utilizes precision fly-cutting or face-milling operations with diamond-tipped inserts, achieving flatness within 0.001″ and Ra values below 32 microinches directly from machining. Climate-controlled manufacturing environments maintain stable temperatures during machining operations, preventing thermal expansion that could compromise dimensional accuracy on large heat sink bases. Advanced workholding systems distribute clamping forces to prevent distortion of thin-walled sections.

Our quality control protocols include comprehensive CMM inspection of critical dimensions, optical profilometry for surface finish verification, and flatness measurement using precision indicators and coordinate measuring systems. Thermal performance validation through heat dissipation testing and thermal resistance measurement ensures components meet design specifications. Statistical process control monitors key parameters across production runs, guaranteeing consistent thermal performance.

D. Aplicações e casos de utilização

Precision-machined cooling systems and heat sinks enable reliable thermal management across diverse consumer electronics applications:

- Laptop and Notebook Computers: Ultra-thin heat pipes, CPU/GPU heat sinks, and integrated cooling modules for high-performance portable computing

- Desktop Computer Components: Tower coolers, low-profile heat sinks, and liquid cooling cold plates for processors, graphics cards, and chipsets

- Gaming Consoles: Custom heat sink assemblies with optimized airflow channels for sustained gaming performance and quiet operation

- Smartphone Thermal Solutions: Vapor chamber heat spreaders, graphite thermal pads, and miniature heat sinks for flagship device thermal management

- Tablet Computing Devices: Thin-profile heat spreaders and thermal interface components for fanless cooling in compact form factors

- Network Equipment: Rack-mounted heat sinks and cooling assemblies for routers, switches, and telecommunications hardware

- High-Power Audio Amplifiers: Heavy-duty heat sinks with extended fin arrays for professional and consumer audio equipment thermal management

E. Why Choose Yicen Precision for Cooling Systems and Heat Sinks?

Yicen Precision delivers unmatched expertise in cooling systems and heat sinks CNC machining through our specialized thermal management manufacturing capabilities. Our rapid prototyping services enable quick design validation with functional heat sink prototypes delivered within days, allowing thermal testing and design optimization before production commitment. We offer seamless scalability from prototype development through high-volume manufacturing, maintaining precision and thermal performance specifications regardless of order quantity.

Our engineering team provides comprehensive DFM consultation focused on thermal optimization, including fin geometry recommendations, base plate flatness improvements, and manufacturing efficiency enhancements that reduce costs while maximizing heat dissipation. We collaborate with your thermal engineers to refine designs using computational analysis and empirical testing data.

Complete material traceability with certified mill test reports ensures thermal conductivity specifications are met and documented. Our cost-effective approach leverages efficient machining strategies, optimized tool paths, and waste reduction techniques that deliver superior cooling systems and heat sinks at competitive pricing without compromising thermal performance or dimensional accuracy.

With dedicated project management, transparent communication throughout development and production, and reliable on-time delivery, we become your trusted partner for bringing thermally optimized consumer electronics products to market.