Yes, we offer various post-processing services, including deburring, anodizing, plating, and heat treatment, to ensure your drilled parts meet specific surface finish and functional requirements.

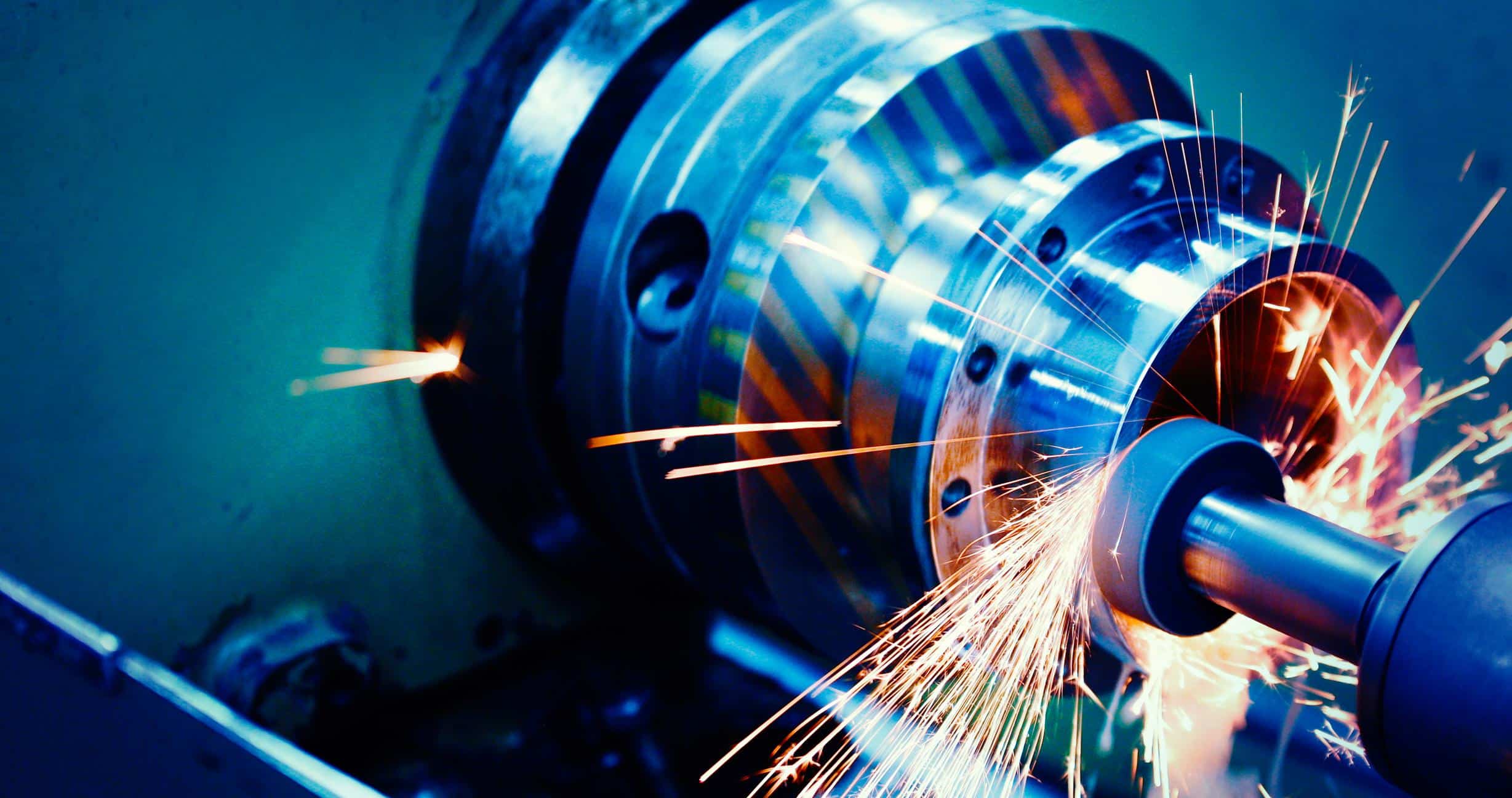

Get precise CNC drilling services for metals and plastics with fast turnaround and high accuracy. Our advanced CNC machines offer tight tolerances (down to ±0.001″) for a wide range of hole sizes, from micro to large-scale, ensuring repeatable quality across prototypes and production runs. We support industries like aerospace, automotive, and medical, and work with materials such as aluminum, steel, titanium, and plastics, all backed by ISO 9001:2015, AS9100D, and ISO 13485 certifications.

ISO 9001:2015 | AS9100D | ISO 13485 | ITAR Compliant

Yicenprecision Instant Quoting Engine is covered by U.S. Pat. Nos. 11,086,292, 11,347,201, 11,693,388, 11,698,623, 12,099,341, and 12,189,361. Other patents pending.

CNC drilling is a high-precision machining process used to create accurate and repeatable holes in both metal and plastic components. Unlike manual drilling, CNC drilling uses computer-controlled systems for precise positioning and repeatability, ensuring consistent hole sizes and depth across both prototypes and production parts. This advanced process delivers clean, accurately located holes with predictable geometry, making it ideal for complex and high-accuracy applications.

CNC drilling ensures consistent hole diameter, depth, and positioning with each operation.

CNC drilling offers higher repeatability, faster production, and better precision compared to traditional manual methods.

CNC machines support various configurations, from basic straight-hole drilling to advanced multi-axis and deep-hole drilling.

At Yicen Precision, We deliver high-precision CNC drilling with tight tolerances and exceptional accuracy, ensuring each hole meets the required specifications for your project. Our CNC drilling capabilities include precise hole diameter, depth, and positional accuracy for both prototypes and production runs.

The following table highlights our typical drilling tolerances, hole straightness, repeatability, and when secondary operations like reaming may be required for your parts.

|

Operation |

Typical Tolerances |

Positional Accuracy |

Hole Straightness & Repeatability |

Secondary Operations Required |

|

Standard Drilling |

±0.001″ (±0.025 mm) |

±0.0005″ (±0.0127 mm) |

Consistent hole positioning |

Reaming for tight tolerances |

|

Deep Hole Drilling |

±0.002″ (±0.05 mm) |

±0.001″ (±0.025 mm) |

Straightness guaranteed up to 10x diameter |

Reaming for smooth finishes |

|

Precision Drilling |

±0.0005″ (±0.0127 mm) |

±0.0002″ (±0.005 mm) |

Excellent repeatability |

May require deburring or finishing operations |

When choosing materials for CNC drilling, it’s important to consider the properties that best suit your project’s needs. At Yicen Precision, we specialize in handling a wide range of materials, ensuring high-quality results with precision.

|

Property |

Description |

Finishing Options |

Common Applications |

|

Grade |

6061, 7075, 2024 |

Anodizing, Powder Coating, Polishing |

Aerospace, Automotive, Construction |

|

Density |

2.70 g/cm³ |

Polishing |

Structural Components, Furniture |

|

Strength |

Moderate to High Strength |

Polishing, Cladding |

Military, Marine |

|

Corrosion Resistance |

Excellent corrosion resistance |

Electroplating |

Outdoor Equipment, Appliances |

|

Thermal Conductivity |

235 W/m·K |

Polishing, Anodizing |

Electrical, Heat Exchangers |

|

Property |

Description |

Finishing Options |

Common Applications |

|

Grade |

Mild Steel, Alloy Steel, Stainless Steel |

Polishing, Painting |

Automotive, Industrial, Machinery |

|

Density |

7.85 g/cm³ |

Electroplating |

Construction, Structural Components |

|

Strength |

High Strength |

Powder Coating |

Oil & Gas, Industrial Equipment |

|

Hardness |

Moderate to High |

Polishing, Electroplating |

Manufacturing, Aerospace |

|

Corrosion Resistance |

Moderate to Good |

Painting |

Marine, Automotive |

|

Property |

Description |

Finishing Options |

Common Applications |

|

Grade |

C1100, C1200 |

Polishing, Electroplating |

Electrical Components, Heat Exchangers |

|

Density |

8.96 g/cm³ |

Electroplating, Coating |

Industrial Applications |

|

Electrical Conductivity |

Excellent electrical conductivity |

Polishing, Electroplating |

Power Systems, Electronics |

|

Corrosion Resistance |

Good resistance to atmospheric conditions |

Plating, Coating |

Marine, Plumbing Systems |

|

Strength |

Moderate strength |

Coating |

Automotive, Electronics |

|

Property |

Description |

Finishing Options |

Common Applications |

|

Grade |

304, 316, 430 |

Polishing, Electropolishing |

Medical Equipment, Food Processing |

|

Density |

8.03 g/cm³ |

Polishing, Coating |

Industrial, Aerospace |

|

Strength |

High Strength |

Electroplating, Passivation |

Structural, Aerospace |

|

Corrosion Resistance |

Excellent resistance to rust and oxidation |

Polishing, Passivation |

Marine, Chemical Processing |

|

Durability |

Highly durable for extreme conditions |

Polishing, Powder Coating |

Pharmaceutical, Electrical Systems |

|

Property |

Description |

Finishing Options |

Common Applications |

|

Grade |

Grade 2, Grade 5 |

Polishing, Anodizing |

Aerospace, Medical Implants |

|

Density |

4.43 g/cm³ |

Polishing, Coating |

Industrial Equipment, Marine |

|

Strength |

High Strength |

Anodizing, Cladding |

Aerospace, Military |

|

Corrosion Resistance |

Excellent resistance to corrosion |

Polishing, Electroplating |

Power Plants, Marine Applications |

|

Biocompatibility |

Ideal for medical implants |

Electroplating |

Medical Implants, Surgical Equipment |

|

Property |

Description |

Finishing Options |

Common Applications |

|

Grade |

C36000, C37700 |

Polishing, Plating |

Plumbing, Electrical Connectors |

|

Density |

8.73 g/cm³ |

Polishing, Coating |

Automotive, Aerospace |

|

Strength |

Moderate to High |

Coating, Powder Coating |

Marine, Decorative Items |

|

Corrosion Resistance |

Excellent corrosion resistance |

Electroplating, Anodizing |

Electrical, Decorative Parts |

|

Machinability |

High machinability |

Anodizing, Polishing |

Precision Components |

|

Property |

Description |

Finishing Options |

Common Applications |

|

Grade |

General-purpose thermoplastic |

Polishing, Coating, Painting |

Automotive, Consumer Electronics |

|

Strength |

Moderate impact resistance and toughness |

Electroplating |

Home Appliances, Toys |

|

Density |

1.04 g/cm³ |

Powder Coating |

Medical Devices, Office Equipment |

|

Thermal Resistance |

Moderate resistance to heat |

Painting, Polishing |

Medical, Automotive |

|

Machinability |

Easy to machine |

Electroplating, Painting |

Engineering, Industrial Components |

|

Property |

Description |

Finishing Options |

Common Applications |

|

Grade |

PA6, PA66 |

Polishing, Electroplating |

Automotive, Industrial, Robotics |

|

Strength |

High strength, wear-resistant |

Polishing, Anodizing |

Electrical, Mechanical Components |

|

Density |

1.14 g/cm³ |

Coating, Powder Coating |

Electrical Insulation, Manufacturing |

|

Friction Resistance |

Low friction, good for bearing applications |

Painting, Coating |

Gear Parts, Machine Components |

|

Durability |

Excellent durability under high-stress conditions |

Polishing, Electroplating |

Industrial, Aerospace |

|

Property |

Description |

Finishing Options |

Common Applications |

|

Grade |

Acetal Copolymer |

Polishing, Coating, Electroplating |

Automotive, Aerospace |

|

Strength |

High strength, high stiffness |

Polishing, Anodizing |

Gears, Bearings, High-Precision Parts |

|

Density |

1.41 g/cm³ |

Coating, Powder Coating |

Electrical Components, Machinery Parts |

|

Durability |

Wear-resistant and low friction |

Polishing, Electroplating |

Medical Devices, Food Processing |

|

Machinability |

Excellent machinability |

Polishing, Coating |

High-Precision Parts |

|

Property |

Description |

Finishing Options |

Common Applications |

|

Grade |

General-purpose, optical quality |

Polishing, Coating |

Medical Devices, Optical Lenses |

|

Impact Resistance |

Extremely high impact resistance |

Polishing, Electroplating |

Safety Equipment, Machine Covers |

|

Density |

1.20 g/cm³ |

Powder Coating |

Electrical Panels, Signage |

|

Clarity |

Transparent, optically clear |

Coating, Polishing |

Optical Instruments, LED Components |

|

Strength |

High strength, high-temperature resistance |

Powder Coating |

Medical Equipment, Aerospace |

|

Property |

Description |

Finishing Options |

Common Applications |

|

Grade |

Ultra-High Molecular Weight Polyethylene |

Coating, Painting |

Food Processing, Industrial Equipment |

|

Durability |

Extremely durable and wear-resistant |

Polishing |

Bearings, Bushings |

|

Density |

0.93 g/cm³ |

Painting, Coating |

Material Handling Systems, Packaging |

|

Friction Resistance |

Extremely low friction |

Electroplating |

Textile Machinery, Medical Equipment |

|

Strength |

High strength, low wear |

Powder Coating |

Food Processing, Industrial Parts |

At Yicen Precision, we focus on providing the most accurate and efficient CNC drilling solutions. To ensure precision and reduce machining time, it’s essential to follow specific design guidelines. These guidelines not only improve accuracy but also help in maintaining stable part geometry during the drilling process. Below are some important parameters and tips for designing your CNC drilling projects.

|

Parameter |

Specification |

Recommended Guidelines |

Benefits |

|

Minimum Hole Diameter |

Minimum diameter of 0.020” (0.50 mm) depending on tool availability. |

Use larger diameters for better chip evacuation and reduced tool wear. |

Improves efficiency and reduces tool wear. |

|

Hole Depth-to-Diameter Ratio |

Recommended maximum depth of 4× diameter for optimal performance. |

For deeper holes, consider using reaming or boring processes to enhance accuracy. |

Achieves precision in deeper holes. |

|

Hole Spacing Guidelines |

Maintain adequate space between holes to avoid tool interference. |

Minimum spacing of 2× diameter is ideal for precision holes. |

Prevents tool interference and improves results. |

|

Tolerance Callouts |

Tolerances for CNC drilling range from ±0.001” to ±0.005” depending on complexity. |

Specify precise tolerance levels based on the material and hole size for better accuracy. |

Achieves exact specifications and quality. |

|

Undercuts |

Support profiles like square, full radius, and dovetail. |

Avoid excessive undercuts, as they may require specialized tooling and increase cost. |

Ensures clean and efficient cuts. |

|

Threaded Holes |

Thread depth should be 3× the diameter for small threads (Ø1.5-6 mm). |

Custom threads available for specific applications like aerospace and medical. |

Adds versatility for fasteners and bolts. |

|

Surface Finish |

Common finishes include anodizing, polishing, and coating. |

Select finishes based on material compatibility and end-use (e.g., anodizing for aluminum). |

Enhances part aesthetics and durability. |

|

Design for Manufacturability (DFM) |

Review part designs for manufacturability to avoid complex geometries. |

Minimize sharp internal corners, thin walls, and excessive features. |

Reduces machining time and cost. |

|

Cost Optimization |

Avoid unnecessary features like unsupported tabs or thin walls. |

Use standard tooling and design simple geometries to reduce costs. |

Streamlines production and reduces costs. |

|

Text & Engraving |

Minimum text height: 0.6 mm width and 0.1 mm depth. |

For turned parts, consider laser engraving for fine markings. |

Adds custom identification and enhances usability. |

At Yicen Precision, we provide a range of surface finishing options and post-processing treatments to enhance the performance and durability of your drilled parts. Each finish is carefully chosen to meet the specific needs of your application, ensuring superior quality and functionality.

The most economical option, leaving visible tool marks and edges. Ideal for applications where surface finish is not critical.

A process that removes sharp edges and burrs, ensuring smoother surfaces and reducing the risk of injury or damage during assembly.

Creates a smooth, matte finish by using abrasive media. It enhances aesthetic appeal and improves surface texture for a uniform, clean finish.

A chemical treatment that enhances the corrosion resistance and durability of aluminum parts. It also provides a decorative, matte finish.

Adds a thin metallic layer (such as nickel or chrome) to the surface of the part, improving corrosion resistance, wear properties, and aesthetics.

A process used to alter the physical properties of the material, improving strength, hardness, and durability for high-performance applications.

Need a specific finish? Submit an RFQ, and we’ll work with you to find a tailored solution for your project.

Creates a smooth, matte finish by media-blasting, typically with glass beads, offering an improved aesthetic and uniform surface texture.

At Yicen Precision, we prioritize quality and precision in every CNC drilling operation. Each unit undergoes rigorous inspection to ensure that the final product meets the highest standards of accuracy and performance. Our inspection process complies with ISO 9001:2015, AS9100D, and ISO 13485 standards, ensuring traceability and acceptance across industries.

We use advanced measurement systems to verify hole sizes, ensuring they meet the specified tolerances for accuracy and functionality.

CNC drilling is closely monitored for precise hole placement, ensuring perfect alignment and positioning with every part.

Each part is thoroughly inspected for visual defects and dimensional accuracy, ensuring that all features match the required specifications.

We provide comprehensive reports, including material certificates (MTRs), FAI (First Article Inspection) reports, and CMM (Coordinate Measuring Machine) data sheets, ensuring full transparency in our quality assurance process.

Discover our expert precision cnc machining services, where accuracy meets performance at every stage. From intricate prototypes to production-ready components, our custom cnc machining services deliver high-accuracy parts. Every cut, every contour, crafted with exceptional quality, consistency, and attention to detail.

Easily upload your CAD files through our secure online platform to get started.

Choose your material, finish, tolerances, and preferred lead time to match your project needs.

Receive a real-time quote based on your design and selected specifications, no delays.

Your parts are manufactured by trusted partners, quality-checked, and delivered to your door on time.

At Yicen Precision, We offer exceptional CNC drilling services that prioritize quality, precision, and efficiency. Here are six reasons why you should choose us for your next project.

Our team is skilled in delivering highly accurate and consistent drilling results, ensuring every hole meets your specifications.

We use state-of-the-art CNC machinery to achieve top-notch precision, speed, and repeatability for both prototypes and high-volume production runs.

With our advanced equipment and efficient processes, we guarantee quick turnaround times without compromising quality, ensuring your project is delivered on schedule.

Whether you need a single prototype or a large batch of parts, we support both low and high-volume production with consistent results.

Our experienced engineers provide technical support and design feedback to ensure your parts are optimized for manufacturing, improving efficiency and reducing costs.

We use high-quality materials that meet industry standards, ensuring reliable performance and durability for every drilled component.

Yicen Precision is serving a broad spectrum of industries, covering aerospace, automotive, electronics, medical, and more. We specialize in providing high-quality, reliable parts tailored to meet the unique engineering challenges of each industry.

Advantages

CNC Drilling offers numerous advantages that improve production efficiency and product quality. At Yicen Precision, our CNC drilling services ensure high-precision and repeatable results, making it ideal for various industries and applications.

Applications

CNC Drilling is utilized across various industries to create high-precision holes for a wide range of components. At Yicen Precision, our CNC drilling services are perfect for producing parts that require tight tolerances and high-quality finishes.

We specialize in converting your ideas into high-quality, functional components with unparalleled speed and accuracy. With advanced technology and expert craftsmanship, we create parts that meet the most complex specifications.

Do you provide post-processing services?

Yes, we offer various post-processing services, including deburring, anodizing, plating, and heat treatment, to ensure your drilled parts meet specific surface finish and functional requirements.

Can CNC drilling handle deep hole applications?

Yes, CNC drilling is capable of handling deep hole drilling, ensuring high precision even in long and narrow holes. For greater depth, we use specialized equipment to maintain straightness and accuracy.

What tolerances can CNC drilling achieve?

CNC drilling can achieve highly precise tolerances, typically ranging from ±0.001” to ±0.005”, depending on the material, hole size, and complexity of the design. With our advanced machinery, we can meet the most stringent tolerance requirements.

What is the maximum hole depth CNC drilling can achieve?

The maximum hole depth in CNC drilling is typically 4 times the diameter of the hole. For deeper holes, we recommend reaming or boring to maintain accuracy and improve surface finish.

CNC drilling vs CNC milling: What’s the difference?

CNC drilling focuses on creating holes in materials, whereas CNC milling is used for removing material to create complex shapes and contours. CNC drilling is ideal for high-precision hole-making, while CNC milling provides more flexibility for intricate designs and part shaping.