The surface finish options for Wire EDM depend on the part requirements. For smooth finishes, we offer skim cuts and multi-skim finishes, while As-Cut finishes are perfect for parts that do not require post-machining.

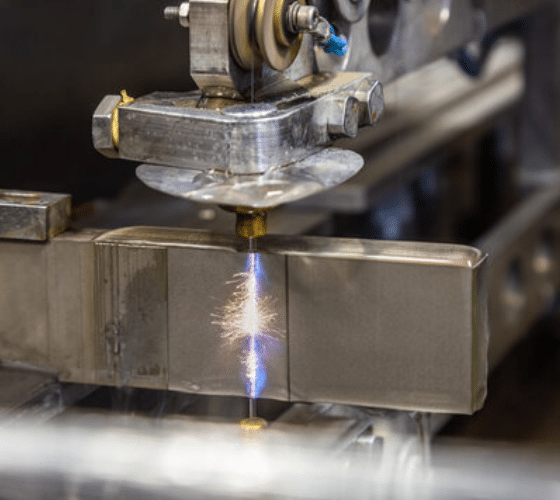

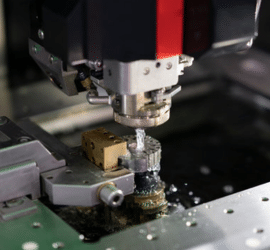

At Yicen Precision, we specialize in Wire EDM machining that delivers high-precision, tight-tolerance cuts for a wide range of metals and plastics. Our advanced technology ensures that your components are made with unmatched accuracy, achieving tolerances down to ±0.001″ (±0.025 mm). Whether you’re working on prototypes or high-volume production runs, we offer fast turnaround times and consistently high-quality results.

ISO 9001:2015 | AS9100D | ISO 13485 | ITAR Compliant

Yicenprecision Instant Quoting Engine is covered by U.S. Pat. Nos. 11,086,292, 11,347,201, 11,693,388, 11,698,623, 12,099,341, and 12,189,361. Other patents pending.

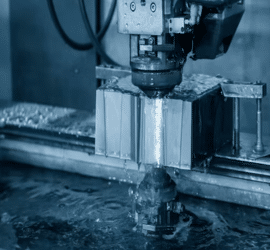

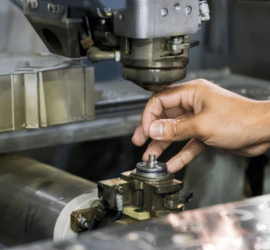

CNC turning is a precision machining process used to create accurate cylindrical and concentric components by removing material from rotating stock. The controlled toolpaths deliver stable diameters, clean surface finishes, and consistent dimensional repeatability for both prototypes and production parts.

A spindle rotates the raw material while cutting tools shape external and internal features such as profiles, bores, grooves, and threads. This method ensures stable geometry and predictable accuracy.

The machine executes programmed feeds, speeds, and tool motions to achieve precise dimensions.

Different types of lathes handle different levels of work, from basic turning of round parts to advanced machines that produce very small or complex shapes. Each type helps improve stability, tool control, and accuracy during machining.

Wire EDM machining offers exceptional precision, making it the perfect choice for intricate parts with tight tolerances. Whether you need standard, high-precision, or micro tolerances, Yicen Precision can meet the most stringent demands across various industries.

|

Tolerance Type |

Achievable Tolerances |

Applications |

Factors Affecting Tolerance |

|

Standard Tolerances |

±0.005″ (±0.127 mm) |

General machining, prototypes |

Wire diameter, material type |

|

High-Precision Tolerances |

±0.001″ (±0.025 mm) |

Aerospace, automotive, medical |

Machine calibration, cutting speed |

|

Micro Tolerances |

±0.0005″ (±0.0127 mm) |

Micro-machining, small parts |

Environmental factors, wire tension |

We provide a range of Wire EDM machining services designed to meet your specific needs. Whether you’re working on prototype parts, production runs, or high-precision components, we offer comprehensive solutions with unmatched precision.

Achieve quick iterations with precision—perfect for prototyping and small batch production. Our Wire EDM service allows for quick prototyping of complex parts with tight tolerances, giving you the flexibility to test designs without compromising on accuracy.

Facilitate multi-step assemblies with accurate part orientation and ergonomic handling.

Efficient and scalable Wire EDM machining for mass production. We offer consistent, high-volume cutting with precise tolerances, ensuring that your production runs are reliable and cost-effective. Our advanced machines allow for seamless transitions from prototype to full-scale production.

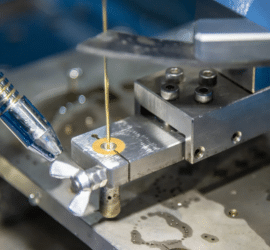

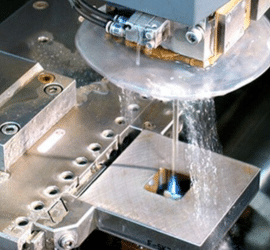

Unmatched precision for micro-machining. Our micro Wire EDM services provide ultra-fine cuts down to ±0.0005″ (±0.0127 mm), ideal for parts requiring high accuracy and fine details. Perfect for industries like medical devices, aerospace, and electronics.

Intricate and complex geometries are no challenge for our Wire EDM services. Whether it’s intricate internal cuts, thin walls, or 3D shapes, our Wire EDM machining can handle your most complex design requirements with precision and repeatability.

High-tolerance components made to your exact specifications. We specialize in achieving tight tolerances, ensuring that every part meets your exact requirements, whether for aerospace, automotive, or tooling applications. Our precision allows you to meet even the most stringent tolerance requirements.

We specialize in cutting a wide range of materials with precision and high-quality results. Here’s a list of materials we commonly work with

|

Material |

Description |

Finishing Options |

Applications |

|

Tool Steel |

Known for its hardness and wear resistance, ideal for tooling. |

Polishing, Coating, Powder Coating |

Cutting tools, Dies, Molds, Tooling |

|

T1 |

High-speed steel with excellent wear resistance. |

Polishing, Powder Coating |

Tool manufacturing, Cutting tools |

|

D2 |

Air-hardening tool steel with high wear resistance. |

Coating, Polishing, Anodizing |

Dies, Press tools, Blades |

|

M2 |

High-speed steel for tooling applications with great toughness. |

Powder Coating, Polishing |

Drills, Reamers, Molds |

|

A2 |

Good for tools requiring both toughness and wear resistance. |

Polishing, Cladding |

Punches, Dies, Blades |

|

Material |

Description |

Finishing Options |

Applications |

|---|---|---|---|

|

Hardened Steel |

Extremely durable with excellent wear resistance, used for heavy-duty parts. |

Polishing, Cladding, Anodizing |

Industrial components, Heavy-duty tools |

|

S7 |

Shock-resistant, high toughness material. |

Powder Coating, Polishing |

Molds, Dies, Hydraulic components |

|

O1 |

Oil-hardening steel used for general tooling. |

Polishing, Coating, Anodizing |

Cutting tools, Dies |

|

D2 |

High wear resistance, suitable for cutting applications. |

Polishing, Cladding |

Industrial machinery, Tools |

|

M2 |

Tool steel with high strength and good hardness. |

Coating, Powder Coating |

Tools, Drills, Mills |

|

Material |

Description |

Finishing Options |

Applications |

|

Carbide |

Exceptionally hard, ideal for precision cutting. |

Polishing, Cladding, Painting |

Aerospace, Medical, Tooling |

|

Tungsten Carbide |

Very high hardness, used for cutting tools. |

Coating, Polishing, Cladding |

Cutting tools, Aerospace, Molds |

|

Cobalt |

Known for wear resistance and high strength. |

Polishing, Anodizing, Coating |

Tooling, Dies, Mold inserts |

|

Ceramic |

Provides high wear resistance and thermal stability. |

Polishing, Cladding |

Precision parts, Electrical components |

|

Solid Carbide |

High precision and long wear life. |

Coating, Polishing |

Tools, Automotive, Aerospace |

|

Material |

Description |

Finishing Options |

Applications |

|

6061 |

Versatile, widely used for structural applications. |

Anodizing, Powder Coating, Polishing |

Aerospace, Automotive, Construction |

|

7075 |

High strength, ideal for aerospace and military applications. |

Anodizing, Powder Coating, Polishing |

Aerospace, Military, High-strength components |

|

2024 |

Known for excellent fatigue resistance. |

Anodizing, Cladding, Painting |

Aerospace, Military, Structural Components |

|

5052 |

Good corrosion resistance and formability. |

Anodizing, Painting, Polishing |

Marine, Automotive, Sheet Metal Work |

|

5083 |

Exceptional performance in extreme environments. |

Anodizing, Powder Coating, Polishing |

Marine, Chemical, Industrial |

|

Material |

Description |

Finishing Options |

Applications |

|

Titanium |

High strength-to-weight ratio, excellent corrosion resistance. |

Anodizing, Polishing, Coating |

Aerospace, Medical implants, Marine |

|

Grade 5 |

Most common titanium alloy, used for high-stress parts. |

Anodizing, Polishing |

Aircraft components, Medical devices |

|

Grade 2 |

Known for corrosion resistance and strength. |

Polishing, Coating |

Marine, Chemical, Aerospace |

|

Grade 9 |

Offers better fatigue and wear resistance. |

Polishing, Anodizing |

Aerospace, Automotive, High-performance parts |

|

Grade 23 |

Superior strength and ductility, used for critical applications. |

Coating, Polishing, Anodizing |

Medical implants, Aerospace |

|

Material |

Description |

Finishing Options |

Applications |

|

Inconel |

High-temperature resistant and durable, used in extreme conditions. |

Polishing, Coating, Anodizing |

Aerospace, Power Generation, Marine |

|

Hastelloy |

Known for excellent corrosion resistance in extreme environments. |

Cladding, Polishing, Coating |

Chemical Processing, Aerospace |

|

Waspaloy |

High strength and oxidation resistance. |

Coating, Polishing, Anodizing |

Aerospace, High-stress components |

|

Monel |

Corrosion-resistant, often used in marine and chemical environments. |

Coating, Polishing |

Marine, Chemical Processing |

|

Nimonic |

Excellent strength at high temperatures. |

Polishing, Coating, Anodizing |

Aerospace, High-temperature environments |

|

Material |

Description |

Finishing Options |

Applications |

|

Copper |

Excellent electrical conductivity, commonly used in electrical wiring. |

Polishing, Plating, Coating |

Electrical parts, Connectors, Heat exchangers |

|

Brass |

Corrosion-resistant, malleable, ideal for decorative parts. |

Anodizing, Polishing, Plating |

Valves, Electrical connectors, Decorative parts |

|

Beryllium Copper |

Combines high strength with excellent conductivity. |

Coating, Polishing, Anodizing |

Electrical, Automotive, Aerospace |

|

Bronze |

Alloy of copper with excellent corrosion resistance. |

Plating, Coating, Polishing |

Marine, Industrial, Electrical |

|

Leaded Brass |

Excellent machinability, often used for threaded parts. |

Polishing, Plating, Anodizing |

Plumbing, Automotive, Electrical |

| Plastic Material | Description | Finishing Options | Applications |

|---|---|---|---|

| ABS | Acrylonitrile Butadiene Styrene, good impact resistance and toughness. | Painting, Plating, Sanding | Automotive Parts, Consumer Products, Enclosures |

| PC | Polycarbonate, high impact resistance and transparency. | Polishing, Sandblasting, Painting | Optical Discs, Safety Equipment, Automotive Parts |

| PMMA | Polymethyl Methacrylate (Acrylic), excellent optical clarity and weather resistance. | Polishing, Sanding, Painting | Displays, Lenses, Lighting Fixtures |

| POM | Polyoxymethylene (Delrin/Acetal), high stiffness and low friction. | Machining, Sanding, Polishing | Gears, Bearings, Medical Devices |

| PEEK | Polyetheretherketone, high temperature and chemical resistance. | Machining, Sanding, Polishing | Aerospace, Medical Implants, Semiconductor Parts |

| PP | Polyphenylene , high mechanical and thermal properties. | Machining, Sanding, Polishing | Automotive, Electrical Components, Industrial Applications |

| PA66 | Polyamide (Nylon 66), high mechanical strength and rigidity. | Machining, Sanding, Polishing | Mechanical Parts, Automotive, Electrical Insulation |

| PEI | Polyetherimide (Ultem), high strength and excellent electrical properties. | Machining, Sanding, Polishing | Aerospace, Medical Devices, Electrical Components |

| SAN | Styrene Acrylonitrile, good chemical resistance and transparency. | Machining, Sanding, Polishing | Housewares, Cosmetic Containers, Automotive Parts |

| HIPE | High Impact Polystyrene, good impact resistance and machinability. | Machining, Sanding, Painting | Packaging, Consumer Products, Electrical Insulation |

| HIPD | High Impact Polypropylene, high impact resistance and low density. | Machining, Sanding, Painting | Automotive Parts, Industrial Applications, Consumer Goods |

| Fiber-Reinforced Materials | Composite materials with enhanced mechanical properties. | Machining, Sanding, Painting | Aerospace, Automotive, Sporting Goods |

To ensure the best results and cost-effective production using Wire EDM, following these design guidelines will help minimize machining time, improve accuracy, and maintain part geometry stability.

|

Parameter |

Specification |

|

Minimum Corner Radius |

Avoid sharp internal corners. Recommended internal radius: 2.6 × tool diameter. For deep pockets, tool length should not exceed 10× diameter for stability. |

|

Hole Start Requirements |

Minimum hole diameter: 0.020” (0.50 mm). For precision holes, boring improves tolerance accuracy (±0.002” typical). For larger holes, jetting or precision drilling is recommended. |

|

Material Thickness Limits |

Metals: 0.3-1.0 mm. Plastics: 1.2-1.5 mm. Thin walls can increase vibration and deflection, which affects machining accuracy. |

|

Hole Sizes & Depth |

Maximum hole depth: 4× diameter. Larger depths may require specialized tools, which could increase machining time and cost. |

|

Undercuts |

Supported profiles: square, full radius, dovetail, and custom reliefs. Complex undercuts may require specialized tools and can increase costs. |

|

Text & Engraving |

Wire EDM Machining text: Minimum 0.6 mm width and 0.1 mm depth. For finer marking or turned parts, laser engraving is preferred. |

|

Avoid Over-Constraint |

Avoid excessive fixturing. Design for stable flat surfaces, supported geometries, and eliminate unsupported tabs and unnecessary complexity. |

|

CAD File Best Practices |

Provide accurate CAD models with proper dimensions and tolerances. Ensure clear views for complex features and maintain dimensioned drawings. |

|

DFM (Design for Manufacturability) Review |

Our engineers will review your part for manufacturability, tolerance risks, tool access, and stability to ensure efficient machining and high-quality output. |

Precision-turned parts benefit from specialized surface treatments that enhance strength, durability, and overall performance. These finishes are ideal for optimizing the functionality of shafts, bushings, and cylindrical components.

The quickest and most economical option, leaving visible tool marks and sharp edges. Surface roughness is approximately 125 pin Ra. Burrs can be removed upon request.

A thick chrome coating that boosts hardness, wear resistance, and durability. Ideal for high-stress parts like shafts and pistons.

A thin electroplated nickel layer that enhances wear and corrosion resistance. Provides a bright, attractive finish for functional parts.

A chemical treatment that creates a dark, matte black surface on steel parts. Offers mild corrosion resistance and reduces light reflection.

A smooth, glossy finish achieved by mechanical buffing, perfect for decorative parts requiring enhanced shine and low roughness.

A linear, satin-like texture created using abrasive belts or brushes, ideal for reducing minor imperfections and providing a clean, decorative appearance.

Need a specific finish? Submit an RFQ, and we’ll work with you to find a tailored solution for your project.

Creates a smooth, matte finish through media blasting, typically with glass beads, offering an improved aesthetic and uniform surface texture.

We adhere to ISO 9001:2015, AS9100D, and ISO 13485 standards, ensuring that every part we produce meets the highest quality benchmarks. Our inspection process is rigorous, covering every stage from prototype development to full production, guaranteeing that each part meets your tolerance and surface finish specifications.

We use CMM (Coordinate Measuring Machines), digital micrometers, and optical measurement systems to check all critical features with micron-level precision.

We ensure that parts meet ISO 2768-mK and ASME Y14.5 standards, verifying accurate form, position, and profile throughout the production process.

We inspect surface roughness (Ra 3.2-0.8 mm) and coating thickness to ensure the performance and appearance of each part meet your requirements.

Discover our expert precision cnc machining services, where accuracy meets performance at every stage. From intricate prototypes to production-ready components, our custom cnc machining services deliver high-accuracy parts. Every cut, every contour, crafted with exceptional quality, consistency, and attention to detail.

Easily upload your CAD files through our secure online platform to get started.

Choose your material, finish, tolerances, and preferred lead time to match your project needs.

Receive a real-time quote based on your design and selected specifications, no delays.

Your parts are manufactured by trusted partners, quality-checked, and delivered to your door on time.

At Yicen Precision, we pride ourselves on providing high-quality Wire EDM machining backed by years of experience and a proven track record in delivering precise, complex, and custom parts for a wide range of industries.

We deliver parts with tight tolerances (±0.001″ or better), ensuring top-quality precision for your projects.

With experience in aerospace, medical, and automotive, we’ve built a reputation for high-precision machining in demanding industries.

Quick prototyping and rapid production to meet your tight deadlines, without compromising quality.

Specializing in intricate designs and complex geometries, we turn the most challenging projects into reality.

Our engineering team provides expert guidance on material selection, tolerances, and design for manufacturability to optimize production.

We offer tailored Wire EDM services to meet your specific project requirements, delivering the best possible results every time.

Yicen Precision is serving a broad spectrum of industries, covering aerospace, automotive, electronics, medical, and more. We specialize in providing high-quality, reliable parts tailored to meet the unique engineering challenges of each industry.

Advantages

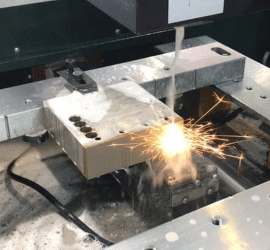

Wire EDM provides several benefits that make it ideal for manufacturing complex parts and high-precision components.

Applications

Wire EDM is widely used across industries for high-precision parts, offering the ability to cut complex shapes and tight tolerances with ease.

We specialize in converting your ideas into high-quality, functional components with unparalleled speed and accuracy. With advanced technology and expert craftsmanship, we create parts that meet the most complex specifications.

How Do I Choose the Right Surface Finish for My Wire EDM Project?

The surface finish options for Wire EDM depend on the part requirements. For smooth finishes, we offer skim cuts and multi-skim finishes, while As-Cut finishes are perfect for parts that do not require post-machining.

What Tolerances Can Wire EDM Achieve?

Wire EDM can achieve tolerances as tight as ±0.001″ (±0.025 mm), making it ideal for high-precision parts in industries such as aerospace, automotive, and medical devices.

How Accurate Is Wire EDM Machining?

Wire EDM is known for its unmatched accuracy, delivering parts with tight tolerances and the ability to cut intricate geometries. It offers high-precision machining for even the most complex parts.

Can Wire EDM Machine Hardened Steel?

Yes, Wire EDM is highly effective in machining hardened steels and other tough materials. It is especially useful for cutting high-hardness materials that other machining methods may struggle with.

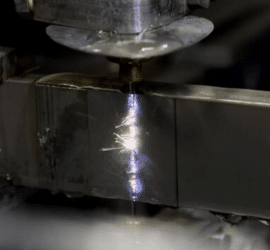

How Does Wire EDM Compare to Laser Cutting?

Unlike laser cutting, which uses heat, Wire EDM offers contact-free machining with no heat-affected zones, making it ideal for precise cuts in small or delicate parts and materials that may distort under heat.

What Is the Typical Lead Time for Wire EDM?

The lead time for Wire EDM projects varies depending on the part complexity and order size, but prototypes typically take 1-3 days, while full production runs may take 1-2 weeks.

What Types of Materials Can Be Used with Wire EDM?

Wire EDM works with a wide range of materials, including metals (tool steel, titanium, copper, brass, etc.), alloys, exotic materials, and hard plastics, making it a versatile choice for many applications.

Can Wire EDM Handle Complex Geometries?

Yes, Wire EDM is perfect for creating intricate and complex geometries that other methods, like CNC milling, might struggle with. It allows for tight curves, internal features, and small holes in detailed designs.