Moderne Betriebe nutzen CAD/CAM in der CNC-Technik, um schnell von 3D-Modellen zu präzisen Teilen zu gelangen. In diesem Leitfaden wird erläutert, wie integrierte Software die Programmierung verbessert, den Einrichtungsaufwand verringert und die Qualität erhöht. Sie sehen einfach verständliche Grundlagen, schrittweise Arbeitsabläufe, Schlüsselparameter, eine Vergleichstabelle, ein reales Beispiel und kurze Fragen und Antworten. Links zu den Dienstleistungen von Yicen sind enthalten, damit Sie direkt vom Lernen zu einem Angebot übergehen können.

CAD und CAM im Bearbeitungsalltag

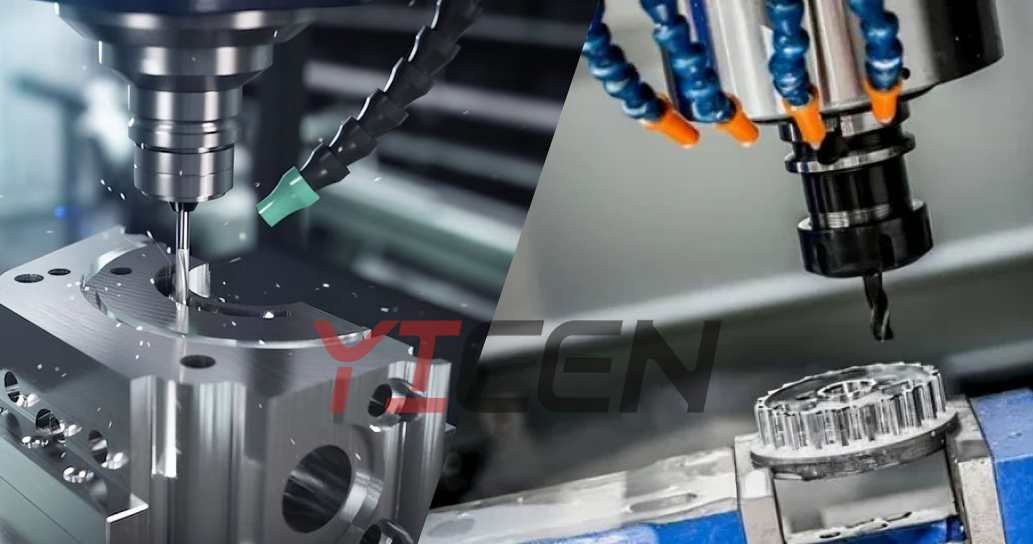

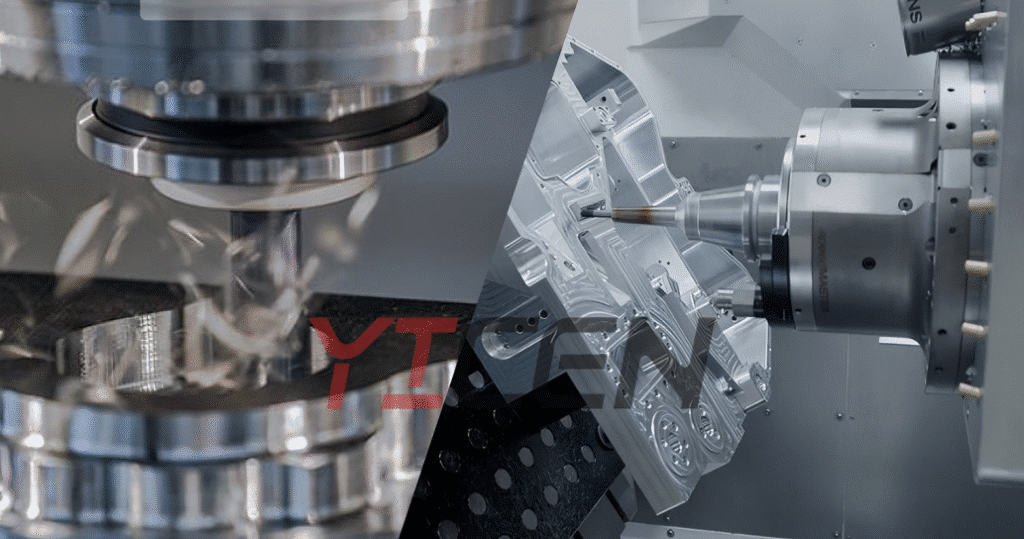

In einem typischen Arbeitsablauf erstellen die Konstruktionsteams das 3D-Modell und die Zeichnung, dann generieren die Programmierer die Werkzeugwege und den G-Code, der die Maschine steuert. Die computergestützte Konstruktion definiert die Geometrie und PMI (Toleranzen, GD&T), während die computergestützte Fertigung diese Definition in sichere, effiziente Werkzeugbewegungen für Fräsmaschinen, Drehbänke und Fräs-Dreh-Maschinen umsetzt. Die maßgeblichen Referenzen beschreiben CAM als Software, die Werkzeugmaschinen ansteuert und in der digitalen Kette auf CAD folgt; G-Code ist der gemeinsame CNC Sprache, die Maschinen ausführen.

Die PMI-Arbeit des NIST zeigt, warum die Qualität der vorgelagerten CAD-Daten wichtig ist: Wenn die Informationen zur Produktherstellung korrekt modelliert sind, können sie verifiziert und mit weniger Übersetzungsfehlern in die nachgelagerte Fertigung und Inspektion übertragen werden. Das verbessert die Ergebnisse an der Maschine und in der Qualitätssicherung.

Warum sich Integration für die Produktion auszahlt

Wenn Konstruktion und Programmierung durchgängig digital erfolgen, sind weniger Schritte manuell, und es unterlaufen weniger Fehler. Integriertes CAD/CAM in der CNC-Bearbeitung verkürzt die Einrichtungszeit, reduziert die Programmierzeit und verbessert die Ausbeute der ersten Teile, indem eine genaue Geometrie mit Werkzeugwegen kombiniert wird, die das Modell und die Toleranzen berücksichtigen. Die Branchenberichterstattung zeigt die Trends auf, die hinter diesen Gewinnen stehen: intelligentere Werkzeugwegstrategien, stärkere Partnerschaften zwischen Software- und Maschinenherstellern und bessere Konnektivität für Simulation und Überprüfung.

Vom Modell zur Maschine, ein einfacher Arbeitsablauf

Der nachstehende Ablauf spiegelt wider, wie fähige Geschäfte vom Hochladen bis zum Chippen vorgehen und dabei die Daten intakt und die Risiken gering halten.

- Entwurf fertig: Sie erhalten STEP oder natives CAD mit klaren PMI. Solides computergestütztes Design reduziert Vermutungen und beschleunigt DFM. Die NIST-Arbeit betont die PMI-Integrität für die nachgelagerte Verwendung.

- Intelligentes Programm: In der CAM wählen Sie Werkzeuge, Halter und Strategien aus, legen das Rohmaterial und die Spannvorrichtungen fest und erzeugen dann die Bahnen. Dies ist der Bereich, in dem die computergestützte Fertigung glänzt.

- Simulieren und Prüfen: Führen Sie eine Simulation der gesamten Maschine und des Materialabtrags durch; prüfen Sie Reichweite, Kollisionen und Restmaterial. SME stellt fest, dass moderne Verifikations- und Werkzeugbibliotheken die Einrichtungszeit verkürzen.

- Posten und beweisen: Verwenden Sie den richtigen Postprozessor, damit die Ausgabe mit Ihrer Kontrolle übereinstimmt (z. B., Fanuc, Siemens, Heidenhain, usw.). Die Stelle übersetzt generische Werkzeugwege in maschinenspezifischen G-Code.

- Prüfen und kontrollieren: Stellen Sie das erste Teil her, messen Sie die kritischen Merkmale und stellen Sie dann Vorschübe, Geschwindigkeiten und Antastungen ein, damit der Auftrag zuverlässig wiederholt werden kann.

Parameter, die die Ergebnisse beeinflussen

Eine Handvoll Einstellungen steuert Wärme, Spanfluss, Werkzeugstandzeit und Finish. Die richtigen Einstellungen im CAM-System verbessern sowohl die Geschwindigkeit als auch die Qualität in der Fertigung.

- Schnittgeschwindigkeit und Drehzahl: Wird durch Material und Werkzeug bestimmt; eine zu hohe Oberflächengeschwindigkeit erhöht die Hitze und den Verschleiß.

- Vorschub pro Zahn oder pro Umdrehung: Beeinflusst die Spandicke und das Finish; ein zu leichter Span führt zu Reibung, ein zu schwerer zu Bruch.

- Stepdown und Stepover: Ausgewogene Zykluszeit, Durchbiegung und Aushöhlungshöhe; adaptives Schruppen hält die Last konstant, um die Werkzeuge zu schützen.

- Radius und Geometrie der Werkzeugschneide: Beeinflusst die Verarbeitung und das Klappern; passt sich dem Material und der Strategie an.

- Kühlmittel- und Späneabsaugung: Unverzichtbar für die Standzeit und Maßhaltigkeit der Werkzeuge.

Universitäten und Fachleute verknüpfen diese Parameter direkt mit der Wendeplattensorte, dem Material und der Werkzeugwegstrategie, und sie werden in computergestützter Fertigungssoftware ausgewählt und gesteuert.

Was CAD/CAM bei CNC am meisten verbessert

Ohne es als separates "Framework" zu bezeichnen, lässt sich der Wert auf einige vorhersehbare Vorteile reduzieren, die Einkäufern, Ingenieuren und QA-Teams helfen, Termine und Spezifikationen einzuhalten.

- Weniger manuelle Übergaben: Ein sauberer computergestützter Entwurf in CAM bedeutet weniger Übersetzungen und neu eingegebene Spezifikationen.

- Schnellere Programmierung: Merkmalserkennung und vorgefertigte Strategien automatisieren Routineaufgaben.

- Besserer Erfolg im ersten Teil: Kollisionsprüfungen und Bestandssimulationen decken Probleme auf, bevor es die Maschine tut.

- Kürzere Zykluszeiten: Hochgeschwindigkeitsschruppen und Restmaterialbearbeitung reduzieren den Luftschnitt und erhalten die Spanbelastung.

- Gleichmäßigere Qualität: Auf Ihre Kontrolle abgestimmte Beiträge verringern die Bearbeitung auf der Maschine; das Sondieren schließt den Kreis.

In den Berichten der KMU über die CAD/CAM-Entwicklung werden die Automatisierung bewährter Verfahren und die wissensbasierte Bearbeitung als wichtige Triebkräfte für diese Verbesserungen hervorgehoben.

Argumente für CAD/CAM in der CNC-Technik

Dies ist der Moment, in dem das Modell aufhört, "Konstruktion" zu sein, und zur "Fertigung" wird. Wenn CAD/CAM in der CNC-Technik gut eingerichtet ist, arbeiten die Post, das Maschinenmodell und die Werkzeugbibliothek zusammen. Das Ergebnis ist ein vorhersehbarer Code, weniger Überraschungen und eine sichere Terminplanung. G-Code ist nach wie vor die Lingua franca der CNC, und genaue Postings stellen sicher, dass das, was Sie simulieren, auch von der Steuerung ausgeführt wird.

Vergleich für Planung und ROI

| Szenario | Profis | Nachteile | Beste Passform |

| Nur manuelle Programmierung | Volle Kontrolle über die Maschine; keine Softwarekosten | Langsam, fehleranfällig, schwer zu wiederholen; begrenzte Simulation | Einmalige Optimierungen, einfache Legacy-Aufgaben |

| CAD mit handcodierten Werkzeugwegen | Präzise Geometrie; minimale Lizenzen | Zeitaufwendig, schwache Kollisionsprüfungen, Stammeswissen | Einfache Platten, Befestigungen und Wartung |

| Integriertes CAD/CAM in CNC | Schnelle Programmierung; Simulation; Vorlagen; geprüfte Stellen; digitale Kontinuität | Lizenz- und Einführungsaufwand | Produktionsläufe, komplexe Teile, mehrachsige Arbeiten |

Die unabhängige Abdeckung verknüpft Produktivitätssteigerungen mit Fortschritten bei den CAM-Werkzeugwegen und einer stärkeren Verifizierung - beides zentrale Vorteile eines integrierten Ansatzes.

Branchenübergreifende Anwendungen in den USA

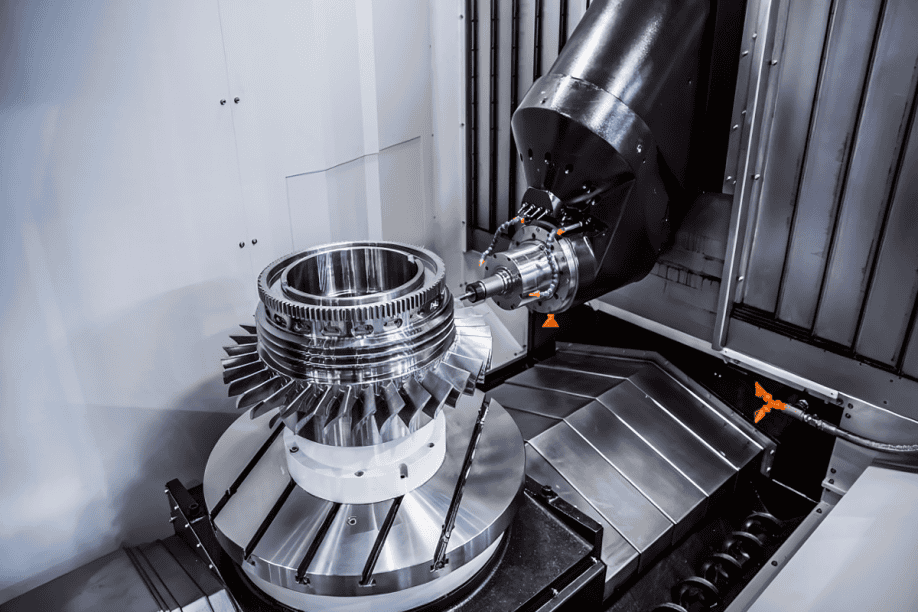

Die Geschäfte wenden diese Instrumente an in Luft- und Raumfahrt Klammern, medizinisch Gehäuse, Robotikrahmen, Automobil Werkzeugbau und Verbrauchsgüter. Die Kombination aus computergestütztem Design und computergestützter Fertigung sorgt dafür, dass diese Ziele vom Modell bis zur Inspektion im Blick bleiben. Für Käufer, die ihre Lieferanten konsolidieren, kann Yicen die Programmierung, Bearbeitung, Endbearbeitung und Inspektion in einem Angebot zusammenfassen, um die Vorlaufzeit und die Übergabezeiten zu verkürzen.

Software auswählen und durchsetzen

Bei der Wahl des "besten CAD/CAM" geht es weniger um die Marke als vielmehr um die Eignung. Konzentrieren Sie sich auf Datenintegrität, Beiträge, Bibliotheken und Schulungen, damit Sie im ersten Monat sichtbare Erfolge erzielen.

- Daten und PMI: Bevorzugen Sie CAD, das PMI zuverlässig überträgt; die Arbeit des NIST an CAD-to-CAM-to-CMM dient dazu, dies interoperabel zu machen.

- Nachbearbeitungsprogramme: Vergewissern Sie sich, dass Ihre Steuerungen unterstützt werden; ein guter Post ist nicht verhandelbar. Sowohl Wikipedia als auch die OEM-Anleitung beschreiben den Post als Übersetzer zwischen CAM-Pfaden und Maschinencode.

- Werkzeugbibliotheken und Vorlagen: Investieren Sie einen Tag, um Halter, Fräser, Vorschübe und Standardstrategien zu standardisieren; die Zeit macht sich bei jedem Auftrag bezahlt.

- Verifizierung und Simulation: Nutzen Sie die maschinennahe Simulation, um Überlauf und Kollisionen vor dem Einrichten zu erkennen. Artikel aus der Industrie zeigen, dass diese Werkzeuge die Einrichtungszeit erheblich verkürzen.

- Ausbildung und Übernahme: Wählen Sie kurze, praktische Sitzungen, die sich auf Ihre Teile beziehen. Das Ziel sind wiederholbare Ergebnisse, keine Softwaretheorie.

Häufige Fallstricke und wie man sie vermeidet

Vermeiden Sie diese Muster, und Sie schützen Budgets und Zeitpläne, insbesondere in den ersten Monaten der Einführung.

- Lose Modelldisziplin: Fehlende oder inkonsistente PMI führt zu falschen Annahmen an der Maschine.

- Allgemeine Stellen: Unangepasste Pfosten führen zu Veränderungen auf dem Boden und unterbrechen die Verbindung zwischen Simulation und Realität.

- Zu enge Toleranzen: Wenn ein Gesicht nur kosmetisch ist, lassen Sie es sein; sparen Sie sich strenge Spezifikationen für das, was die Funktion bestimmt.

- Ignorieren der Chipkontrolle: CAM legt die Strategie fest, aber Kühlmittel und Spanabfuhr halten die Wendeplatten am Leben.

- Überspringen der Probezeit: Trockenübungen und Antastroutinen verhindern Ausschuss beim ersten Stück.

Reales Beispiel aus der Produktion

A Robotik Der Kunde benötigte 200 Aluminiumgehäuse mit strengen Positionstoleranzen über drei Flächen und mehrere dünnwandige Taschen. Das Team verwendete eine computergestützte Konstruktion mit vollständiger PMI und erstellte dann CAM-Schablonen für Schruppen, Restmaterialbearbeitung und Schlichten. Die maschinennahe Simulation erkannte einen Reichweitenkonflikt an einer tiefen Tasche, der durch einen einfachen Halterwechsel noch vor dem Einrichten behoben wurde. Mit abgestimmten Pfosten und geprüften Werkzeugwegen traf der erste Artikel alle Spezifikationen. Mit denselben Schablonen wurde dann ein Satz rostfreier Halterungen hergestellt, was beweist, wie sich die computergestützte Fertigung mit minimaler Neuprogrammierung auf verschiedene Materialien übertragen lässt.

Schnelle Fragen und Antworten

Welche Dateiformate eignen sich am besten für die Programmierung?

STEP mit einer bemaßten PDF-Datei ist die häufigste Übergabeform. Natives CAD ist in Ordnung, wenn beide Seiten das gleiche System verwenden. PMI im Modell hilft bei der nachgelagerten Überprüfung, insbesondere wenn man bedenkt, wie CAD/CAM in CNC-Bearbeitungsprozessen den Datentransfer rationalisieren und Fehler reduzieren.

Brauche ich für jede Maschine einen anderen Pfosten?

Häufig ja. Ein Beitrag zielt auf eine bestimmte Steuerung und manchmal auf ein bestimmtes Maschinenmodell ab, um Kinematik und Codes genau zu spiegeln. Dies ist ein Schlüsselaspekt dafür, wie CAD/CAM in CNC-Bearbeitungsprozessen die Kompatibilität und Effizienz zwischen verschiedenen Geräten gewährleistet.

Ist G-Code noch Standard?

Ja. G-Code, standardisiert aus RS-274, ist nach wie vor die primäre CNC-Sprache; verschiedene Steuerungen haben Dialekte, weshalb Stellen wichtig sind.

Kann CAM die Zykluszeit wirklich verkürzen?

Hochgeschwindigkeits-Werkzeugwege, Restschruppen und verifizierter Eingriff können den Zeitaufwand drastisch reduzieren und gleichzeitig die Werkzeugstandzeit verlängern, wie die Industrie berichtet.

Wo soll ich anfangen, wenn ich auslagern will?

Senden Sie Ihre CAD-Daten, Mengen und Termine an YicenVerlangen Sie DFM und ein Programmierkonzept, bevor Sie sich festlegen.