Custom CNC Turning Services

High-precision CNC turning solutions for prototypes and production parts that demand consistent accuracy, smooth surface finishes, and stable dimensional performance. Our multi-axis turning centers deliver reliable results across metals and engineering plastics, supported by ISO-certified quality processes and fast global turnaround.

- Todas las cargas son seguras y confidenciales

Iniciar un nuevo presupuesto CNC

ISO 9001:2015 | AS9100D | ISO 13485 | Conformidad con ITAR

Yicenprecision Instant Quoting Engine está amparado por las Pat. Nos. 11,086,292, 11,347,201, 11,693,388, 11,698,623, 12,099,341, y 12,189,361. Otras patentes pendientes.

What Is CNC Turning?

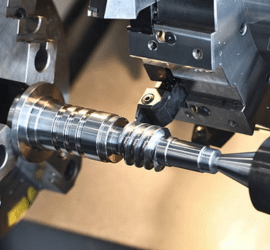

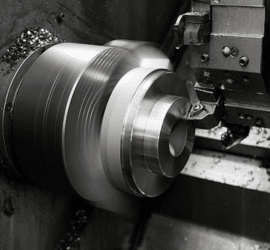

CNC turning is a precision machining process used to create accurate cylindrical and concentric components by removing material from rotating stock. The controlled toolpaths deliver stable diameters, clean surface finishes, and consistent dimensional repeatability for both prototypes and production parts.

How CNC Lathes Operate

A spindle rotates the raw material while cutting tools shape external and internal features such as profiles, bores, grooves, and threads. This method ensures stable geometry and predictable accuracy.

Turning Configurations

Different types of lathes handle different levels of work, from basic turning of round parts to advanced machines that produce very small or complex shapes. Each type helps improve stability, tool control, and accuracy during machining.

Turning Workflow

The machine executes programmed feeds, speeds, and tool motions to achieve precise dimensions.

Maximum CNC Turning Capabilities

Our CNC turning capabilities are engineered for consistent accuracy, smooth finishes, and efficient production cycles across metal and plastic components. Each setup supports reliable machining for both prototypes and large-batch manufacturing.

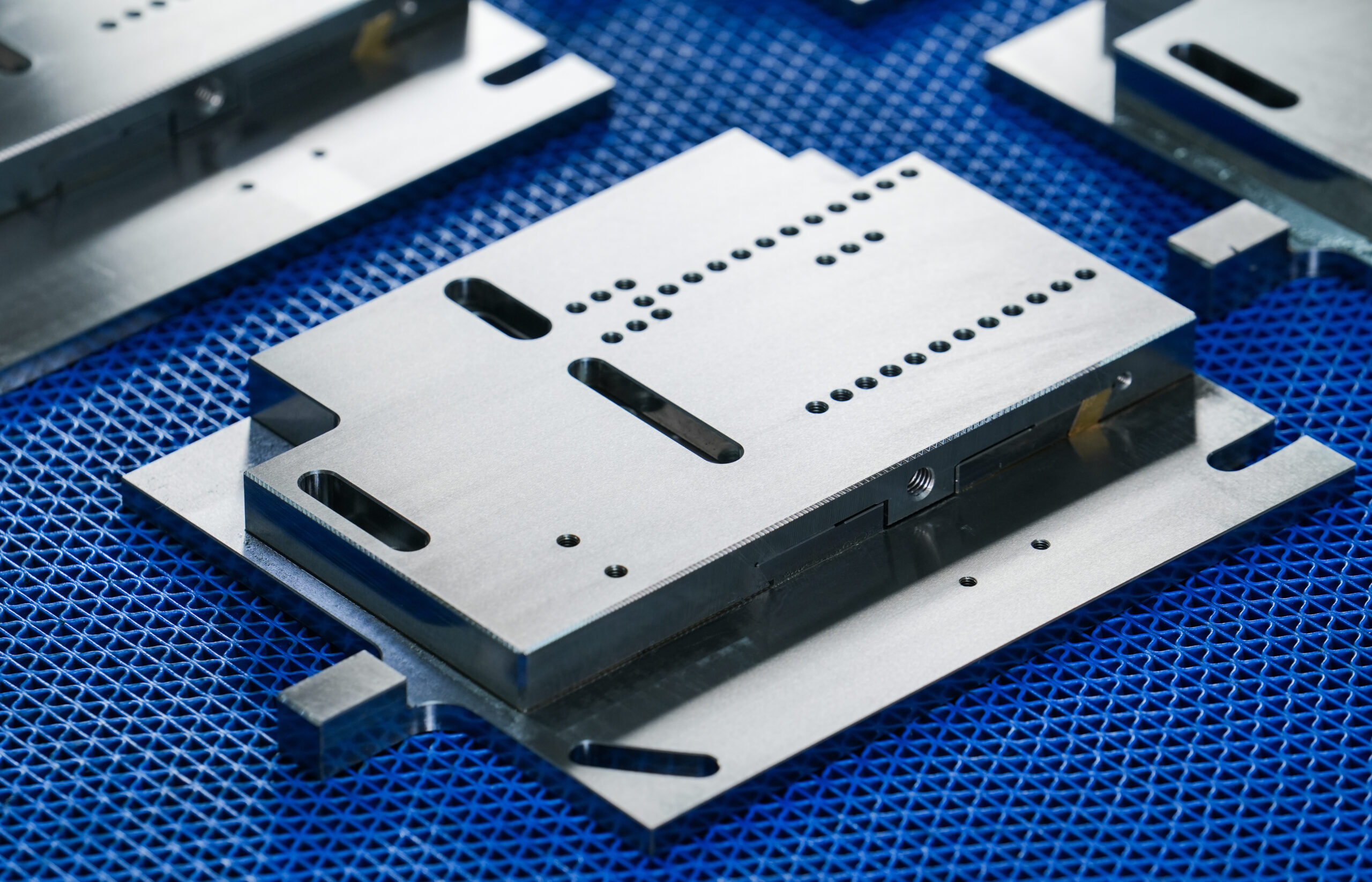

El fresado CNC es una técnica de mecanizado sustractivo que consiste en cortar metal y material plástico en forma de formas precisas y repetibles utilizando máquinas de 3, 4 y 5 ejes. Es la más adecuada para geometrías complicadas, tolerancias estrictas y acabados superficiales elevados en prototipos y componentes de producción.

We provide precision CNC machining services for custom parts in metals and engineering plastics. From prototypes to production runs, every component is machined to tight tolerances with consistent, repeatable accuracy.

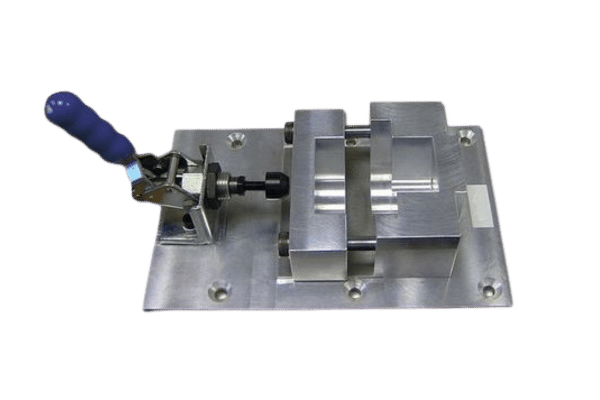

Diseñamos y fabricamos plantillas y utillajes de precisión que mejoran los procesos de mecanizado, montaje e inspección. Nuestras fijaciones se fabrican mediante operaciones CNC de alta precisión para que sean estables, repetibles y duraderas en entornos de fabricación de lotes pequeños y grandes volúmenes.

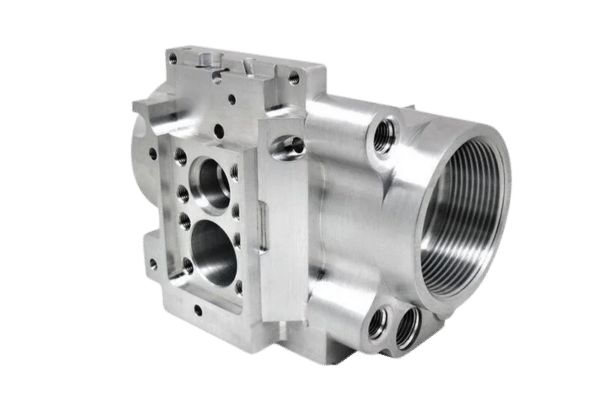

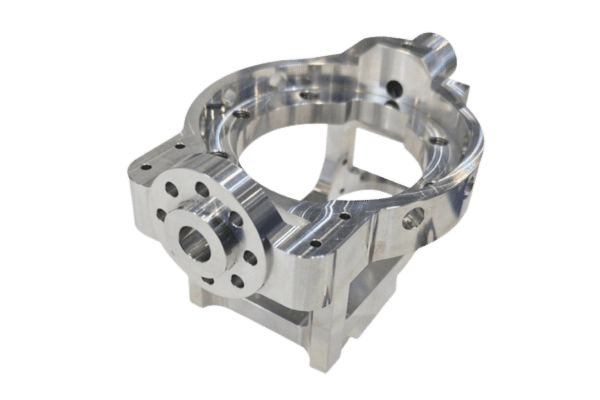

CNC Turned Parts for Precision Components

Descubra a nuestros expertos precision cnc turning services, where accuracy meets performance at every stage. From intricate prototypes to production-ready components, our custom cnc turning services deliver high-accuracy parts. Every cut, every contour, crafted with exceptional quality, consistency, and attention to detail.

Materiales para torneado CNC

Ingenieros y fabricantes líderes confían en Yicen Precision para obtener iteraciones rápidas y piezas duraderas de alto rendimiento. Ya sea para la creación de prototipos o la producción a gran escala, nuestra amplia selección de materiales garantiza precisión, resistencia y fiabilidad para cualquier proyecto de mecanizado CNC.

Aluminio

Aluminio 5052

Aluminio 7075 y 7075-T6

Aluminio 6063-T5

Aluminio 7050-T7451

Aluminio MIC-6

Aluminio 6061-T6

Aluminio 2024-T3

Bronce/latón

Latón C360

Latón 260

C932 M07 Cojinete Bronce

Cobre

H59

H60

Plásticos

ABS

Acetal [Delrin]

Acrílico, G-10 Garolite

Nylon 6/6

PEEK

Policarbonato

PTFE [Teflón]

Polipropileno

Polietileno de peso molecular ultra alto

Acero

Acero aleado 4130

Acero aleado 4140

ASTM A36

Acero inoxidable 15-5

Acero inoxidable 17-4

Acero inoxidable 18-8

Acero inoxidable 303

Acero inoxidable 304

Acero inoxidable 316/316L

Acero inoxidable 416

Acero inoxidable 420

Acero 1018

Acero A36

Titanio

Titanio Grado 2

Titanio 6Al-4V

Zinc

Chapa de zinc Aleación 500

CNC Turning Tolerances

Our turning centers support a wide range of diameters, lengths, and feature types, ensuring reliable machining for small precision components and larger rotational parts.

| Operación | Max Diameter | Max Length |

|---|---|---|

| Standard Turning | Ø300 mm | 500 mm |

| Live Tooling | Ø250 mm | 400 mm |

| Swiss-Type Turning | Ø32 mm | 150 mm |

Acabado de superficies para torneado CNC

Las piezas torneadas de precisión se benefician de tratamientos superficiales especializados que mejoran la resistencia, la durabilidad y el rendimiento general. Estos tratamientos son ideales para optimizar la funcionalidad de ejes, casquillos y componentes cilíndricos.

La opción más rápida y económica, ya que deja marcas visibles de herramientas y bordes potencialmente afilados o rebabas. La rugosidad de la superficie es de aproximadamente 125 µin Ra, y las rebabas pueden eliminarse bajo pedido.

Un grueso revestimiento de cromo que aumenta la dureza, la resistencia al desgaste y la durabilidad. Perfecto para piezas sometidas a grandes esfuerzos, como ejes y pistones.

Una fina capa de níquel electrodepositado que mejora la resistencia al desgaste y a la corrosión. Proporciona un acabado brillante y atractivo a las piezas funcionales.

Tratamiento químico que crea una superficie negra mate y oscura en las piezas de acero. Ofrece una leve resistencia a la corrosión y reduce la reflexión de la luz.

Acabado liso y brillante obtenido mediante pulido mecánico. Ideal para piezas decorativas que requieren mayor brillo y poca rugosidad.

Textura lineal satinada creada mediante bandas abrasivas o cepillos. Reduce las pequeñas imperfecciones y ofrece un aspecto limpio y decorativo.

¿Necesita un acabado específico? Envíe una solicitud de oferta y trabajaremos con usted para encontrar una solución a medida para su proyecto.

Crea un acabado liso y mate mediante granallado, normalmente con microesferas de vidrio, que ofrece una textura superficial uniforme y una estética mejorada.

Key Features of CNC Turning

Our CNC turning capabilities are engineered for consistent accuracy, smooth finishes, and efficient production cycles across metal and plastic components. Each setup supports reliable machining for both prototypes and large-batch manufacturing.

| Heading | Descripción |

|---|---|

| High Dimensional Accuracy | Stable spindle control and rigid toolpaths maintain tight diameter, roundness, and concentricity requirements. |

| Smooth Surface Finishes | Rotational cutting produces clean surfaces ideal for sealing fits, sliding interfaces, and precision assemblies. |

| Efficient for Cylindrical Geometries | Cost-effective machining for shafts, bushings, pins, connectors, and other rotational components. |

| Fast Setup & Short Lead Times | Turning centers allow quick tool changes and reduced cycle time, supporting rapid prototyping and scaling. |

| Live Tooling Support | Add milled flats, threads, grooves, slots, or cross-holes in a single setup for better accuracy and lower cost. |

| Stable Repeatability for Production | Rigid fixturing and automated toolpath control deliver consistent part geometry across long production runs. |

CNC Turning Design Guidelines

Effective design choices help reduce machining time, improve accuracy, and maintain stable part geometry during turning.

| Parámetro | Especificación |

|---|---|

| Internal Radii | – Avoid sharp internal corners; CNC tools naturally create radii. – Recommended internal radius: 2.6 × tool diameter. – Deep pockets: tool length should not exceed 10× diameter for stability. |

| Threads & Tapped Holes | – For threads Ø1.5-6 mm: depth = 3× diameter. – For threads Ø6 mm: depth = 4× diameter. – Custom threads and fine-pitch threads available upon request. – For turned parts, laser marking is recommended for identification. |

| Espesor mínimo de pared | – Metals: 0.3-1.0 mm. – Plastics: 1.2-1.5 mm. – Thin walls increase vibration, deflection, and machining marks. |

| Hole Sizes & Depth | – Minimum hole diameter: 0.020″ (0.50 mm) depending on tool availability. – Recommended maximum depth: 4× diameter for reliable chip evacuation. – For precision bores, reaming or boring improves tolerance accuracy (±0.002″ typical). |

| Socava | – Supported profiles: square, full radius, dovetail, and custom reliefs. – Specialized tools may increase machining time or cost. |

| Text & Engraving | – CNC milling text: minimum 0.6 mm width and 0.1 mm depth. – For turned parts or finer marking, laser engraving is preferred. |

| Avoid Over-Constraint | – Parts should not require excessive fixturing; design for stable flat surfaces and supported geometries. – Avoid ultra-thin features, unsupported tabs, and unnecessary complexity. |

| DFM Review Available | – Our engineers check your part for manufacturability, tolerance risks, tool access, and stability — ensuring efficient machining and high-quality output. |

Quality Assurance & Inspection Capabilities

Every turned part is inspected using certified metrology workflows to ensure dimensional accuracy, surface integrity, and repeatable performance across all production volumes.

Precisión dimensional

CMM inspection for critical datums, diameters, roundness, and concentricity

Bore gauges, micrometers, and height systems for fast in-process checks

Supports tight-tolerance features down to ±0.001 in (±0.025 mm)

GD&T & Tolerance Verification

Surface roughness checks (Ra 3.2 μm standard; Ra 0.8 μm optional)

Runout and concentricity measurement for rotational components

Compliance with turning-specific finishing standards

Surface & Finish Testing

Inspection aligned with ISO 2768-mK and ASME Y14.5

Verification of profile, position, perpendicularity, parallelism, circularity

Ensures geometric stability under real machining conditions

Traceability & Reporting

FAI reports, material certificates (MTRs), and CMM data available

Lot tracking for aerospace, medical, and industrial requirements

Secure record-keeping for full audit trail and quality compliance

Industrias a las que servimos

Yicen Precision presta servicio a un amplio espectro de industrias, que abarcan la aeroespacial, la automoción, la electrónica y la médica, entre otras. Estamos especializados en el suministro de piezas fiables y de alta calidad adaptadas a los retos de ingeniería específicos de cada sector.

Applications of CNC Turning

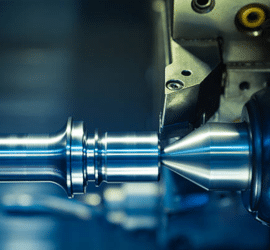

CNC turning is ideal for precision rotational components where concentricity, smooth surface finishes, and consistent dimensional control are critical.

Shafts & Axles

For motors, gear assemblies, automation systems, and drive mechanisms where straightness, runout, and load-bearing interfaces matter.

Bushings & Spacers

High-accuracy cylindrical components for reducing friction, maintaining alignment, and supporting rotational motion.

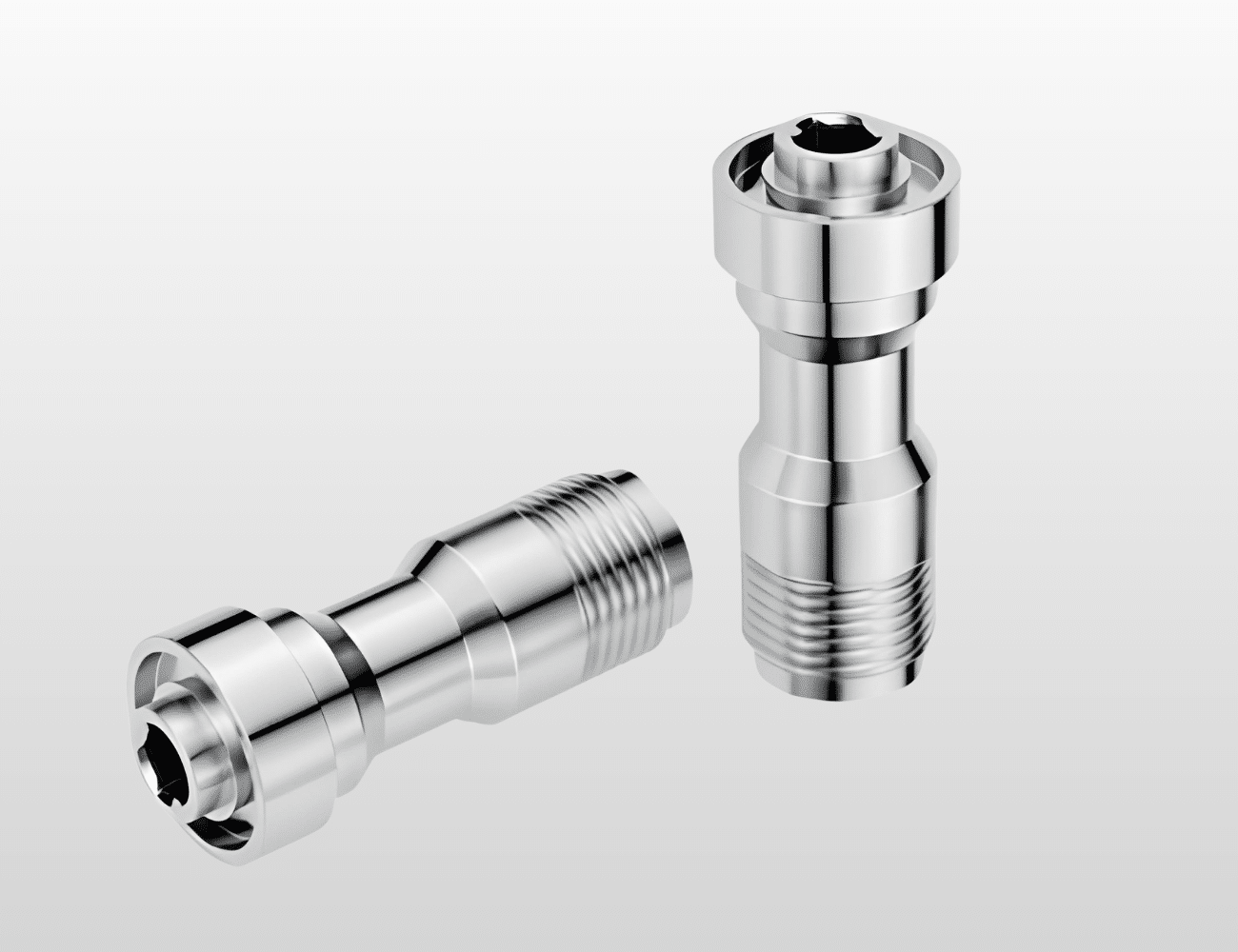

Threaded Connectors & Fittings

Precision internal/external threads for hydraulic, pneumatic, and mechanical systems; supports ISO/ASME thread standards.

Pins, Dowels & Couplers

Used for alignment, load transfer, and joining mechanisms in automotive, aerospace, and machinery assemblies.

Sleeves, Housings & Collars

Turned enclosures and structural rings requiring tight diametrical tolerances and smooth surface profiles.

Hydraulic & Pneumatic Components

Valves, adapters, and pressure-line components requiring concentric sealing surfaces and controlled tolerances.

Custom Rotational Components

Specialized geometries, stepped profiles, and multi-diameter parts for prototypes, tooling, and production assemblies.

Why Choose Yicen Precision to CNC Turning ?

We deliver reliable, production-ready turned parts with consistent accuracy, fast lead times, and engineering support built around real manufacturing requirements.

Micron-Level Precision

Stable, repeatable accuracy down to ±0.001″ for rotational components requiring controlled runout and concentricity.

Advanced Multi-Axis Turning Centers

Live tooling, Swiss-type, and multi-axis equipment allow complex features, reduced setups, and better dimensional consistency.

Support for Manufacturability

Our team reviews geometry, material selection, tolerances, and thread standards to ensure optimal machining and lower cost.

ISO-Certified Quality Systems

ISO-Certified Quality Every part passes through controlled inspection workflows aligned with ISO 9001:2015, AS9100D, and ISO 13485 standards.

Reliable Global Delivery

Secure logistics, protective packaging, and validated workflows ensure parts arrive on time and within specification.

Fast Prototyping & Scalable Production

From rapid prototypes to high-volume production runs, we maintain stable lead times with predictable output.

Soluciones de mecanizado Yicen

Tanto si está creando un pequeño lote de piezas personalizadas como si está ampliando la producción a gran escala, los servicios de mecanizado de Yicen le ofrecen la flexibilidad que necesita.

El mecanizado rápido de prototipos CNC es perfecto para crear prototipos de ingeniería o producción que se asemejan mucho al producto final tanto en apariencia como en funcionalidad. En Yicen, ofrecemos presupuestos instantáneos y entregas rápidas, proporcionándole prototipos mecanizados CNC precisos y de alta calidad para sus necesidades.

- Plazo de entrega: 1-5 días laborables

- Capacidad: 1-100 unidades

- Descuento de 20%

El mecanizado CNC de bajo volumen a menudo actúa como puente entre la creación de prototipos y la producción en serie para la producción nueva y emergente. Con Yicen, este proceso se vuelve más fácil, eficiente y rentable, lo que le permite escalar la producción rápidamente manteniendo los estándares de alta calidad.

- Plazo de entrega: 5-15 días laborables

- Capacidad: 101-10.000 unidades

- Cumplir especificaciones estrictas

El mecanizado de producción CNC es la mejor solución para producir mil piezas o más de forma eficiente. Aprovechando una variada selección de materiales y capacidades de automatización y multieje, Yicen ofrece una producción de gran volumen con tolerancias ajustadas, precisión dimensional superior, alta fiabilidad y plazos de entrega rápidos.

- Plazo de entrega: 2-4 semanas

- Capacidad: Más de 10.001 unidades

- Calidad constante

Preguntas frecuentes

Torneado CNC

What file formats do you accept?

We accept all standard CAD and engineering formats used in CNC machining:

- STEP (.step / .stp)

- IGES (.igs / .iges)

- Parasolid (.x_t / .x_b)

- SolidWorks (.sldprt)

- DXF / DWG for 2D drawings

- PDF for dimensioned technical drawings

Providing a technical drawing with GD&T improves accuracy, especially for parts needing precision CNC turning.

What materials can be turned?

We machine a wide range of metals and engineering plastics commonly used in precision CNC turning. Metals include aluminum (6061, 7075), stainless steel (304, 316, 17-4), carbon steels, brass, copper, titanium, and high-temperature alloys such as Inconel. Plastics such as POM, Nylon, PEEK, PTFE, PVC, and ABS are also supported for custom CNC turned parts. Material selection is validated based on machinability, dimensional stability, and final application requirements.

What tolerances can you achieve?

Typical CNC turning tolerances are ±0.005″, while tight-tolerance CNC turning services can achieve ±0.001″ or better on critical diameters, shoulders, and mating surfaces. Roundness can be controlled to ≤ 0.002″, with concentricity typically held within ≤ 0.005″ depending on geometry and tool access. All tolerance requirements are confirmed during DFM review to ensure the design is manufacturable.

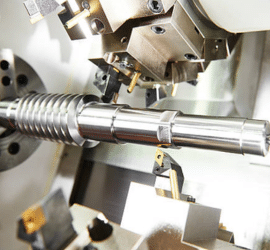

Do you offer live tooling?

Yes. Our CNC turning services include live tooling and multi-axis turning, enabling milling, drilling, slotting, and threading operations within a single setup. This improves concentricity, reduces tool changes, minimizes fixture requirements, and shortens lead time — especially for complex turned-milled components.

What surface finishes do you offer?

We provide a full range of finishing options for metal and plastic turned parts:

- As-turned

- Granallado

- Recubrimiento en polvo

- Anodizing (Type II / Type III)

- Polishing / Electropolishing

- Óxido negro

- Zinc & nickel plating

Finishes are selected based on durability, corrosion resistance, friction behavior, or cosmetic needs. Surface roughness can reach Ra 0.8 μm for high-precision turning applications.

How do you ensure concentricity and runout accuracy?

Concentricity and runout are controlled through:

- Precision collets, soft jaws, and balanced workholding

- Single-setup machining when possible

- Live tooling alignment verification

- Controlled toolpath strategies for rotational accuracy

- CMM inspection of critical features

These methods allow precision CNC turning of parts that require tight alignment across multiple diameters or threaded sections.

Can you handle both prototypes and mass production?

Yes. We support rapid prototype machining, low-volume batches, and high-volume production. Prototypes benefit from flexible tooling and fast machine setup, while production orders leverage automated turning centers, multi-axis operations, and consistent process control. Both small and large quantities receive identical quality assurance steps.

How fast is delivery?

Prototype turned parts can ship in as fast as 1–3 days, depending on complexity, tolerances, and finishing requirements. Low-volume runs typically take 5–10 days, while mass production depends on part count and process routing. All orders follow a predictable schedule, with real-time communication throughout manufacturing.

Transformar conceptos en piezas de precisión

Estamos especializados en convertir sus ideas en componentes funcionales de alta calidad con una rapidez y precisión inigualables. Con tecnología avanzada y artesanía experta, creamos piezas que cumplen las especificaciones más complejas.

- Ingeniería de precisión integral

- Flujos de trabajo de producción racionalizados

- Compromiso con la excelencia en el mecanizado

- Entregas fiables y puntuales

- Todas las cargas son seguras y confidenciales