粉体塗装の初期コストは液体塗装より高いかもしれませんが、長期的には大きなコストメリットがあります。粉体塗装は耐久性に優れているため、再塗装の頻度が少なく、メンテナンスコストを削減できます。さらに、工程が効率的で、余分な粉をリサイクルできるため、長期的には費用対効果の高いソリューションとなります。

精密金属およびプラスチック部品の即座の見積もりと高速回転生産を取得します。Yicenは、高度な3軸、4軸、5軸CNC機械加工によって高精度の部品を提供し、以下の公差を達成します。 ±0.001インチ(±0.025mm) プロトタイプから量産まで、一貫した再現性のある品質を提供します。

ISO 9001:2015|AS9100D|ISO13485|ITAR準拠

第11,086,292号、第11,347,201号、第11,693,388号、第11,698,623号、第12,099,341号、第12,189,361号。その他特許出願中。

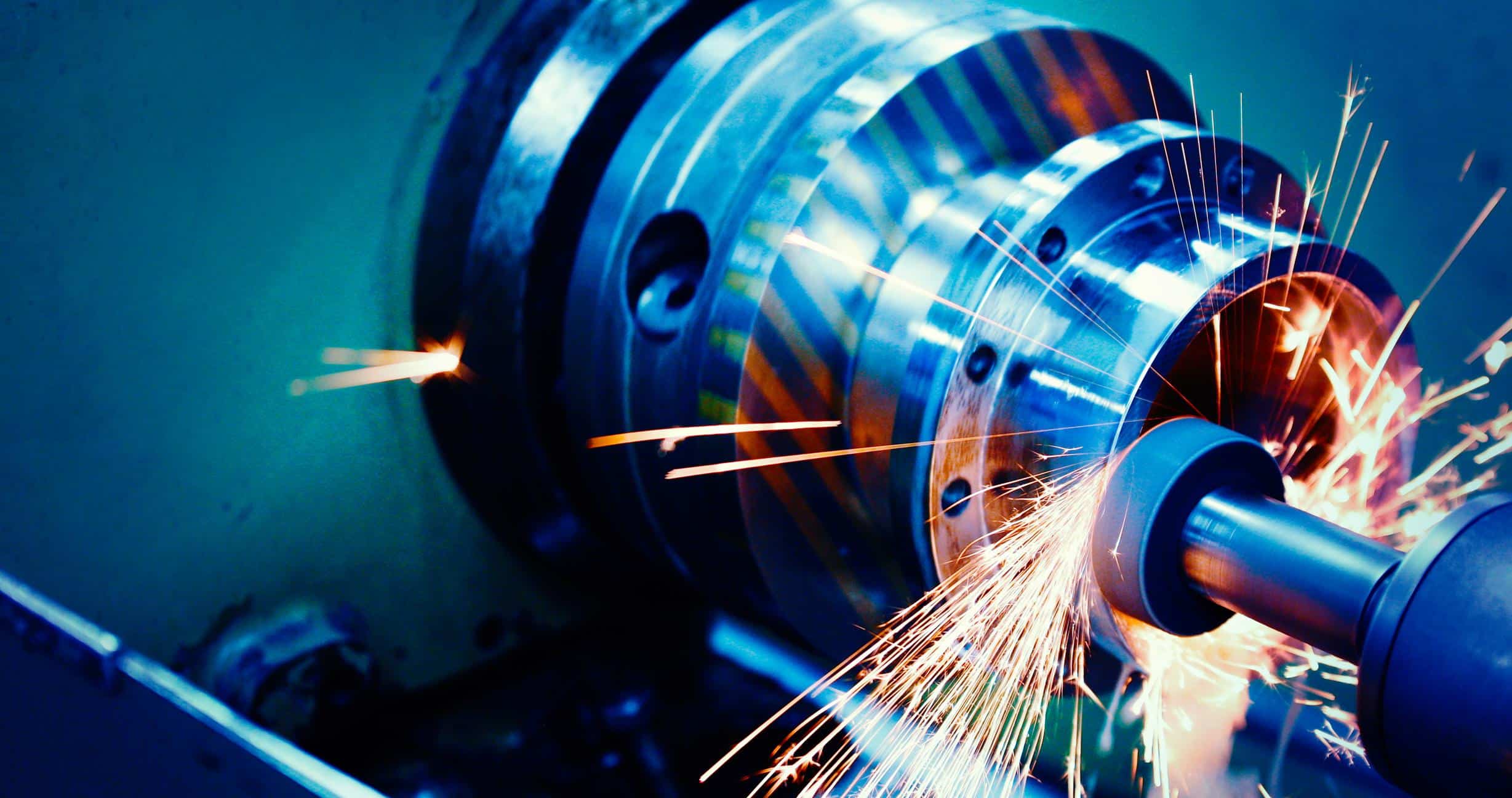

CNC turning is a precision machining process used to create accurate cylindrical and concentric components by removing material from rotating stock. The controlled toolpaths deliver stable diameters, clean surface finishes, and consistent dimensional repeatability for both prototypes and production parts.

A spindle rotates the raw material while cutting tools shape external and internal features such as profiles, bores, grooves, and threads. This method ensures stable geometry and predictable accuracy.

The machine executes programmed feeds, speeds, and tool motions to achieve precise dimensions.

Different types of lathes handle different levels of work, from basic turning of round parts to advanced machines that produce very small or complex shapes. Each type helps improve stability, tool control, and accuracy during machining.

Our Powder coating capabilities are engineered for consistent accuracy, smooth finishes, and efficient production cycles across metal and plastic components. Each setup supports reliable machining for both prototypes and large-batch manufacturing.

Powder coating is a subtractive machining technique which involves cutting metal and plastic material in the form of precise and repeatable shapes using 3-axis, 4-axis and 5-axis machines. Best suited to complicated geometries, strict tolerances, and high surface finishes on prototype and production components.

Powder coating Services is a subtractive machining technique which involves cutting metal and plastic material in the form of precise and repeatable shapes using 3-axis, 4-axis and 5-axis machines. Best suited to complicated geometries, strict tolerances, and high surface finishes on prototype and production components.

Powder coating is a subtractive machining technique which involves cutting metal and plastic material in the form of precise and repeatable shapes using 3-axis, 4-axis and 5-axis machines. Best suited to complicated geometries, strict tolerances, and high surface finishes on prototype and production components.

Powder coating is a subtractive machining technique which involves cutting metal and plastic material in the form of precise and repeatable shapes using 3-axis, 4-axis and 5-axis machines. Best suited to complicated geometries, strict tolerances, and high surface finishes on prototype and production components.

| アルミニウム合金 | 説明 | 仕上げオプション | アプリケーション |

|---|---|---|---|

| 6061 | 汎用性が高く、構造用途によく使用される。 | 陽極酸化、粉体塗装、研磨 | 建設、航空宇宙、自動車 |

| 7075 | 高強度で、航空宇宙および軍事用途に最適。 | 陽極酸化、粉体塗装、研磨 | 航空宇宙、軍事、高強度部品 |

| 2024 | 高い強度と優れた耐疲労性で知られる。 | 陽極酸化処理、クラッディング、塗装 | 航空宇宙、軍事、構造部品 |

| 5052 | 耐食性と成形性に優れ、船舶や自動車用途に使用される。 | 陽極酸化処理、塗装、研磨 | 船舶、自動車、板金 |

| 5083 | 過酷な環境、特に海洋用途で卓越した性能を発揮。 | 陽極酸化処理、塗装、研磨 | 海洋、化学、工業 |

| 6082 | 押出成形性に優れ、建築およびエンジニアリング用途に使用される。 | 陽極酸化、粉体塗装、研磨 | 建築、エンジニアリング、窓枠 |

| 7050 | 高強度で耐応力腐食性があり、航空宇宙分野でよく使用される。 | 陽極酸化処理、クラッディング、塗装 | 航空宇宙、高応力部品 |

| 1100 | 市販の純アルミニウムで、耐食性と加工性に優れている。 | 陽極酸化処理、塗装、研磨 | 化学装置, 食品加工, 熱交換器 |

| 黄銅合金 | 説明 | 仕上げオプション | アプリケーション |

|---|---|---|---|

| C260 | 冷間加工に最適なカートリッジ黄銅。 | メッキ、研磨、ラッカー | 弾薬、熱交換器、配管 |

| C360 | 精密部品に使用される快削黄銅。 | メッキ、研磨、ラッカー | 精密機械加工部品、ファスナー、配管 |

| C353 | 高鉛黄銅、高強度、配管に使用される。 | メッキ、研磨、ラッカー | 配管、ファスナー、バルブ部品 |

| C385 | アーキテクチュラル・ブロンズ、その装飾的魅力の用途。 | メッキ、研磨、ラッカー | 建築用トリム、装飾金物、配管 |

| C272 | 黄銅製で耐食性に優れ、電気部品に使用される。 | メッキ、研磨、ラッカー | 電気部品、ファスナー、配管 |

| 銅合金 | 説明 | 仕上げオプション | アプリケーション |

|---|---|---|---|

| C101 | 無酸素で導電性が高く、電気用途に使用される。 | メッキ、研磨、ラッカー | 導体、スイッチ、端子 |

| C110 | 電解タフピッチ、導電性が高く、電気・配管に使用される。 | メッキ、研磨、ラッカー | 電気配線、配管、バスバー |

| C122 | 脱リン処理され、熱交換器やラジエーターに使用される。 | メッキ、研磨、ラッカー | 熱交換器、ラジエーター、配管 |

| C172 | ベリリウム銅、高強度、航空宇宙や石油掘削に使用される。 | メッキ、研磨、ラッカー | 航空宇宙、石油掘削、スプリングス |

| C194 | 導電性が高く、自動車や電気用途に使用される。 | メッキ、研磨、ラッカー | 自動車用コネクタ、電気コネクタ、スプリング |

| C210 | 低ブラスで延性と強度に優れ、ファスナーや金物に使用される。 | メッキ、研磨、ラッカー | ファスナー、ハードウェア、楽器 |

| C220 | 宝飾品や楽器に使われる商業用青銅。 | メッキ、研磨、ラッカー | 宝飾品、楽器、建築金物 |

| C230 | 建築用途や金物に使用される赤真鍮。 | メッキ、研磨、ラッカー | 建築用途、ハードウェア、配管 |

| グレード | 説明 | 仕上げオプション | アプリケーション |

|---|---|---|---|

| 301 | 被削性に優れ、自動車部品のボルト、ナット、スクリューに使用される。 | 研磨、不動態化、ビーズブラスト | 自動車部品、ボルト、ナット、ネジの製造に使用。 |

| 304 | 最も汎用性が高く、厨房機器のタンク、配管、チューブなどに広く使用されているステンレス鋼。 | 研磨、ブラッシング、不動態化 | 厨房機器、タンク、配管、チューブに使用。 |

| 304L | 304の低炭素バージョンで、化学容器や輸送に使用される。 | 電解研磨、不動態化、ビーズブラスト | 化学薬品の容器や輸送に使用される。 |

| 316 | 耐食性を高めるモリブデンを含み、海洋用途や化学処理装置で使用される。 | 研磨、不動態化、ビーズブラスト | 海洋用途や化学処理装置に使用される。 |

| 316L | 316の低炭素バージョンで、外科用器具や船舶用金具に使用される。 | 電解研磨、不動態化、ビーズブラスト | 手術器具や船舶用金具に使用される。 |

| 410 | マルテンサイト系で、ファスナーや医療器具に使用される。 | 硬化、研磨、不動態化 | ファスナーや医療器具に使用される。 |

| 416 | 高い被削性を持ち、ギア、シャフト、バルブなどに使用される。 | 研磨、不動態化、ビーズブラスト | ギア、シャフト、バルブに使用。 |

| 420 | 硬度が高く、手術器具や刃物に使用される。 | 硬化、研磨、不動態化 | 手術器具やカトラリーに使用される。 |

| 430 | フェライト系で、自動車トリムや食器洗浄機に使用される。 | 研磨、ブラッシング、不動態化 | 自動車トリムや食器洗浄機に使用される。 |

| 合金鋼 | 説明 | 仕上げオプション | アプリケーション |

|---|---|---|---|

| 4140 | 高い靭性と優れた疲労強度を持つクロムモリブデン鋼。 | 熱処理、陽極酸化、粉体塗装 | ギア、シャフト、高応力部品 |

| 4340 | 靭性と強度に優れたニッケル・クロム・モリブデン鋼。 | 熱処理、陽極酸化、粉体塗装 | 航空機着陸装置、自動車部品、重荷重用シャフト |

| 8620 | ニッケル-クロム-モリブデン合金鋼、ケース硬化鋼。 | 浸炭、熱処理、メッキ | ギア、ピン、自動車部品 |

| 1018 | 低炭素鋼、良好な溶接性と機械加工性。 | 塗装、粉体塗装、亜鉛メッキ | 構造用途、シャフト、スピンドル |

| 1045 | 中炭素鋼、高強度、耐衝撃性。 | 熱処理、メッキ、塗装 | ギア、シャフト、機械部品 |

| 4130 | クロムモリブデン合金鋼で、強度と靭性に優れている。 | 熱処理、陽極酸化、粉体塗装 | 航空機部品、自転車フレーム、自動車部品 |

| 1210 | 低炭素鋼、良好な成形性と溶接性。 | 亜鉛メッキ、塗装、粉体塗装 | 自動車部品、機械部品、構造用鋼材 |

| 17-4 PH | 析出硬化ステンレス鋼、高い強度と硬度。 | 熱処理、陽極酸化処理、不動態化処理 | 航空宇宙部品、高強度用途 |

| チタン合金 | 説明 | 仕上げオプション | アプリケーション |

|---|---|---|---|

| グレード1 | 商業純チタン、優れた耐食性と成形性。 | 陽極酸化、研磨、サンドブラスト | 化学処理、海洋、医療 |

| グレード2 | 商用純チタン、強度と延性のバランス。 | 陽極酸化、研磨、サンドブラスト | 航空宇宙、医療、海洋 |

| グレード 5 (Ti-6Al-4V) | 最も一般的に使用されるチタン合金で、高強度、軽量。 | 陽極酸化、研磨、熱処理 | 航空宇宙、医療用インプラント、海洋 |

| 9年生 | 溶接性と冷間成形性に優れたチタン合金。 | 陽極酸化、研磨、サンドブラスト | 航空宇宙、化学処理、海洋 |

| グレード23(Ti-6Al-4V ELI) | グレード5の超低間隙変種、高強度、高靭性。 | 陽極酸化、研磨、熱処理 | 医療用インプラント、航空宇宙、海洋 |

| グレード7 | 耐食性に優れた市販の純チタン。 | 陽極酸化、研磨、サンドブラスト | 化学処理、海洋、医療 |

| 12年生 | 耐食性と強度に優れたチタン合金。 | 陽極酸化、研磨、熱処理 | 化学処理、海洋、航空宇宙 |

| プラスチック素材 | 説明 | 仕上げオプション | アプリケーション |

|---|---|---|---|

| ABS | アクリロニトリル・ブタジエン・スチレン、優れた耐衝撃性と靭性。 | 塗装、メッキ、サンディング | 自動車部品、消費者製品、エンクロージャー |

| PC | ポリカーボネート製で、耐衝撃性と透明性が高い。 | 研磨、サンドブラスト、塗装 | 光ディスク、安全装置、自動車部品 |

| PMMA | ポリメチルメタクリレート(アクリル)、優れた光学的透明性と耐候性。 | 研磨、サンディング、塗装 | ディスプレイ、レンズ、照明器具 |

| POM | ポリオキシメチレン(デルリン/アセタール)、高剛性、低摩擦。 | 機械加工、サンディング、研磨 | ギア、ベアリング、医療機器 |

| 覗き見 | ポリエーテルエーテルケトン、高温、耐薬品性。 | 機械加工、サンディング、研磨 | 航空宇宙、医療用インプラント、半導体部品 |

| PP | ポリフェニレン、高い機械的および熱的特性。 | 機械加工、サンディング、研磨 | 自動車、電気部品、産業用途 |

| PA66 | ポリアミド(ナイロン66)、高い機械的強度と剛性。 | 機械加工、サンディング、研磨 | 機械部品、自動車、電気絶縁 |

| PEI | ポリエーテルイミド(ウルテム)、高い強度と優れた電気特性。 | 機械加工、サンディング、研磨 | 航空宇宙、医療機器、電気部品 |

| サン | スチレン-アクリロニトリル、良好な耐薬品性と透明性。 | 機械加工、サンディング、研磨 | 家庭用品、化粧品容器、自動車部品 |

| ヒップ | 高衝撃性ポリスチレン、優れた耐衝撃性と機械加工性。 | 機械加工、サンディング、塗装 | 包装、消費者製品、電気絶縁 |

| じんこうこていしさん | ハイインパクトポリプロピレン、高い耐衝撃性と低密度。 | 機械加工、サンディング、塗装 | 自動車部品、産業用途、消費財 |

| 繊維強化素材 | 機械的特性を向上させた複合材料。 | 機械加工、サンディング、塗装 | 航空宇宙、自動車、スポーツ用品 |

精密旋盤加工部品は、強度、耐久性、全体的な性能を向上させる特殊な表面処理の恩恵を受けます。これらの処理は、シャフト、ブッシュ、円筒形部品の機能を最適化するのに理想的です。

最も迅速で経済的なオプションで、目に見えるツールマークが残り、鋭利なエッジやバリが発生する可能性がある。表面粗さは約125 µin Raで、ご要望に応じてバリを除去することも可能です。

硬度、耐摩耗性、耐久性を高める厚いクロムコーティング。シャフトやピストンなどの高負荷部品に最適。

耐摩耗性と耐食性を高める薄い電気めっきニッケル層。機能部品に明るく魅力的な仕上げを提供します。

スチール部品の表面を黒くつや消しの黒色にする化学処理。穏やかな耐食性を提供し、光の反射を抑える。

機械的バフ研磨により、滑らかで光沢のある仕上がりが得られます。光沢が必要な装飾部品に最適。

研磨ベルトやブラシを使った、直線的でサテンのようなテクスチャー。細かな凹凸を減らし、きれいで装飾的な外観に仕上げる。

特定の仕上げが必要ですか?RFQをご提出いただければ、お客様のプロジェクトに合わせたソリューションをご提案いたします。

通常ガラスビーズを使用するメディアブラストにより、滑らかでマットな仕上がりを実現。

Our turning centers support a wide range of diameters, lengths, and feature types, ensuring reliable machining for small precision components and larger rotational parts.

| オペレーション | Max Diameter | Max Length |

|---|---|---|

| Standard Turning | Ø300 mm | 500 mm |

| Live Tooling | Ø250 mm | 400 mm |

| Swiss-Type Turning | Ø32 mm | 150 mm |

Effective design choices help reduce machining time, improve accuracy, and maintain stable part geometry during turning.

| パラメータ | 仕様 |

|---|---|

| Internal Radii | – Avoid sharp internal corners; CNC tools naturally create radii. – Recommended internal radius: 2.6 × tool diameter. – Deep pockets: tool length should not exceed 10× diameter for stability. |

| Threads & Tapped Holes | – For threads Ø1.5-6 mm: depth = 3× diameter. – For threads Ø6 mm: depth = 4× diameter. – Custom threads and fine-pitch threads available upon request. – For turned parts, laser marking is recommended for identification. |

| 最小肉厚 | – Metals: 0.3-1.0 mm. – Plastics: 1.2-1.5 mm. – Thin walls increase vibration, deflection, and machining marks. |

| Hole Sizes & Depth | – Minimum hole diameter: 0.020″ (0.50 mm) depending on tool availability. – Recommended maximum depth: 4× diameter for reliable chip evacuation. – For precision bores, reaming or boring improves tolerance accuracy (±0.002″ typical). |

| アンダーカット | – Supported profiles: square, full radius, dovetail, and custom reliefs. – Specialized tools may increase machining time or cost. |

| Text & Engraving | -Powder coating text: minimum 0.6 mm width and 0.1 mm depth. – For turned parts or finer marking, laser engraving is preferred. |

| Avoid Over-Constraint | – Parts should not require excessive fixturing; design for stable flat surfaces and supported geometries. – Avoid ultra-thin features, unsupported tabs, and unnecessary complexity. |

| DFM Review Available | – Our engineers check your part for manufacturability, tolerance risks, tool access, and stability — ensuring efficient machining and high-quality output. |

Our Powder coating centers support a wide range of diameters, lengths, and feature types, ensuring reliable machining for small precision components and larger rotational parts.

| オペレーション | Max Diameter | Max Length |

|---|---|---|

| Standard Turning | Ø300 mm | 500 mm |

| Live Tooling | Ø250 mm | 400 mm |

| Swiss-Type Turning | Ø32 mm | 150 mm |

Every turned part is inspected using certified metrology workflows to ensure dimensional accuracy, surface integrity, and repeatable performance across all production volumes.

CMM inspection for critical datums, diameters, roundness, and concentricity

Bore gauges, micrometers, and height systems for fast in-process checks

Supports tight-tolerance features down to ±0.001 in (±0.025 mm)

Surface roughness checks (Ra 3.2 μm standard; Ra 0.8 μm optional)

Runout and concentricity measurement for rotational components

Compliance with turning-specific finishing standards

Inspection aligned with ISO 2768-mK and ASME Y14.5

Verification of profile, position, perpendicularity, parallelism, circularity

Ensures geometric stability under real machining conditions

FAI reports, material certificates (MTRs), and CMM data available

Lot tracking for aerospace, medical, and industrial requirements

Secure record-keeping for full audit trail and quality compliance

当社の安全なオンラインプラットフォームからCADファイルを簡単にアップロードして、作業を開始できます。

お客様のプロジェクトのニーズに合わせて、材料、仕上げ、公差、ご希望のリードタイムをお選びください。

お客様のデザインと選択された仕様に基づき、リアルタイムでお見積もりをお出しします。

お客様の部品は、信頼できるパートナーによって製造され、品質検査が行われた後、納期通りにお客様のお手元に届けられます。

Advantages

Powder coating provides a range of benefits, ensuring efficient, high-quality production.

アプリケーション

Powder coating is widely utilized in various industries to produce high-precision parts and components:

私たちは、お客様のアイデアを比類のないスピードと精度で、高品質で機能的な部品に変換することを専門としています。高度な技術と熟練した職人技で、最も複雑な仕様を満たす部品を作り出します。

粉体塗装は従来の塗装よりも高価ですか?

粉体塗装の初期コストは液体塗装より高いかもしれませんが、長期的には大きなコストメリットがあります。粉体塗装は耐久性に優れているため、再塗装の頻度が少なく、メンテナンスコストを削減できます。さらに、工程が効率的で、余分な粉をリサイクルできるため、長期的には費用対効果の高いソリューションとなります。

粉体塗装が環境に与える影響とは?

粉体塗装は、従来の液体塗装に比べて環境に優しいオプションです。揮発性有機化合物(VOC)を発生せず、オーバースプレーはリサイクルして再利用できるため、環境への影響は最小限に抑えられます。さらに、粉体塗装は液体塗料ではなく乾燥した粉体を使用するため、廃棄物も少なく、有害廃棄物の処理も少なくて済みます。

粉体塗装の準備はどのようにするのですか?

高品質な粉体塗装を実現するには、適切な準備が不可欠です。部品は徹底的に洗浄し、脱脂して、接着の妨げとなる汚れ、油脂を除去しなければなりません。また、パウダーコートの接着をより効果的にするために、表面をサンドブラストまたは化学エッチングして粗いテクスチャーを作ります。この工程により、滑らかで耐久性のある仕上がりが長持ちします。

粉体塗装は複雑な形にもできますか?

確かに粉体塗装は複雑な形状にも適用できますが、それには入念な準備と専門知識が必要です。Yicen Precisionには、複雑な形状の部品に粉体塗装を施すための設備と経験があります。高度なスプレー技術を駆使し、手の届きにくい部分も含め、すべての表面に均一なコーティングを施します。これにより、形状やサイズに関係なく、すべての部品に一貫した仕上がりが保証されます。

粉体塗装の硬化時間は?

粉体塗装の硬化時間は、材料、塗膜の厚さ、硬化温度によって異なる。一般的に、パウダーコーティングは180℃から200℃のオーブンで約10分から20分かけて硬化させます。この硬化プロセスにより、コーティングが表面にしっかりと接着し、滑らかで耐久性のある仕上がりになります。

粉体塗装の耐久性は?

粉体塗装は耐久性に優れ、傷、腐食、色あせ、欠けに対する優れた保護効果を発揮します。表面と強固に結合するため、自動車部品、屋外家具、産業機械など、過酷な環境にさらされる部品に最適です。硬化仕上げは化学薬品、湿気、紫外線に強く、多くの用途で長持ちします。

粉体塗装にはどんな色がありますか?

パウダーコーティングには、マット、光沢、サテン、テクスチャーなど、さまざまな色と仕上げがあります。黒、白、グレーなどの標準色のほか、お客様のニーズに合わせたカスタムカラーもご用意しています。明るい仕上げをお探しの場合も、より繊細で工業的な外観をお探しの場合も、お客様のプロジェクトに適した色と仕上げをお選びいただけます。

従来の液体塗料と比べた粉体塗装の利点は何ですか?

粉体塗装は、従来の液体塗装に比べ、耐久性に優れ、傷や欠け、色あせに強く、均一な仕上がりになるなど、いくつかの利点があります。また、流れやたるみのない厚い塗膜が得られます。粉体塗装は、揮発性有機化合物(VOC)の発生が少なく、オーバースプレーによる廃棄物も少なくリサイクルできるため、環境に優しい塗装です。