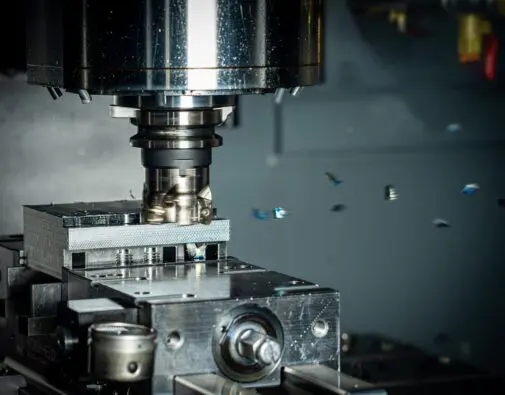

Die Automobilindustrie verlangt mehr als nur einen hohen Ausstoß, sie verlangt Genauigkeit, Wiederholbarkeit und Anpassungsfähigkeit bei einer Vielzahl von Materialien und Geometrien. Die CNC-Bearbeitung erfüllt alle diese Anforderungen und ermöglicht die präzise Fertigung von Komponenten, die sich direkt auf die Sicherheit, Zuverlässigkeit und Effizienz von Fahrzeugen auswirken.

Bei Yicen Precision ist CNC nicht nur ein Prozess, sondern ein Versprechen für Konsistenz, Detailgenauigkeit und technische Spitzenleistungen, die auf Automobilanwendungen zugeschnitten sind.

Die wichtigsten Vorteile von CNC für Automobilteile:

- Enge Toleranzen die Kompatibilität und Leistung gewährleisten

- Gleichbleibende Teilequalität für große und kleine Produktionsmengen

- Unterstützung für verschiedene Materialien wie Aluminium, Titan, Stahl und Polymere

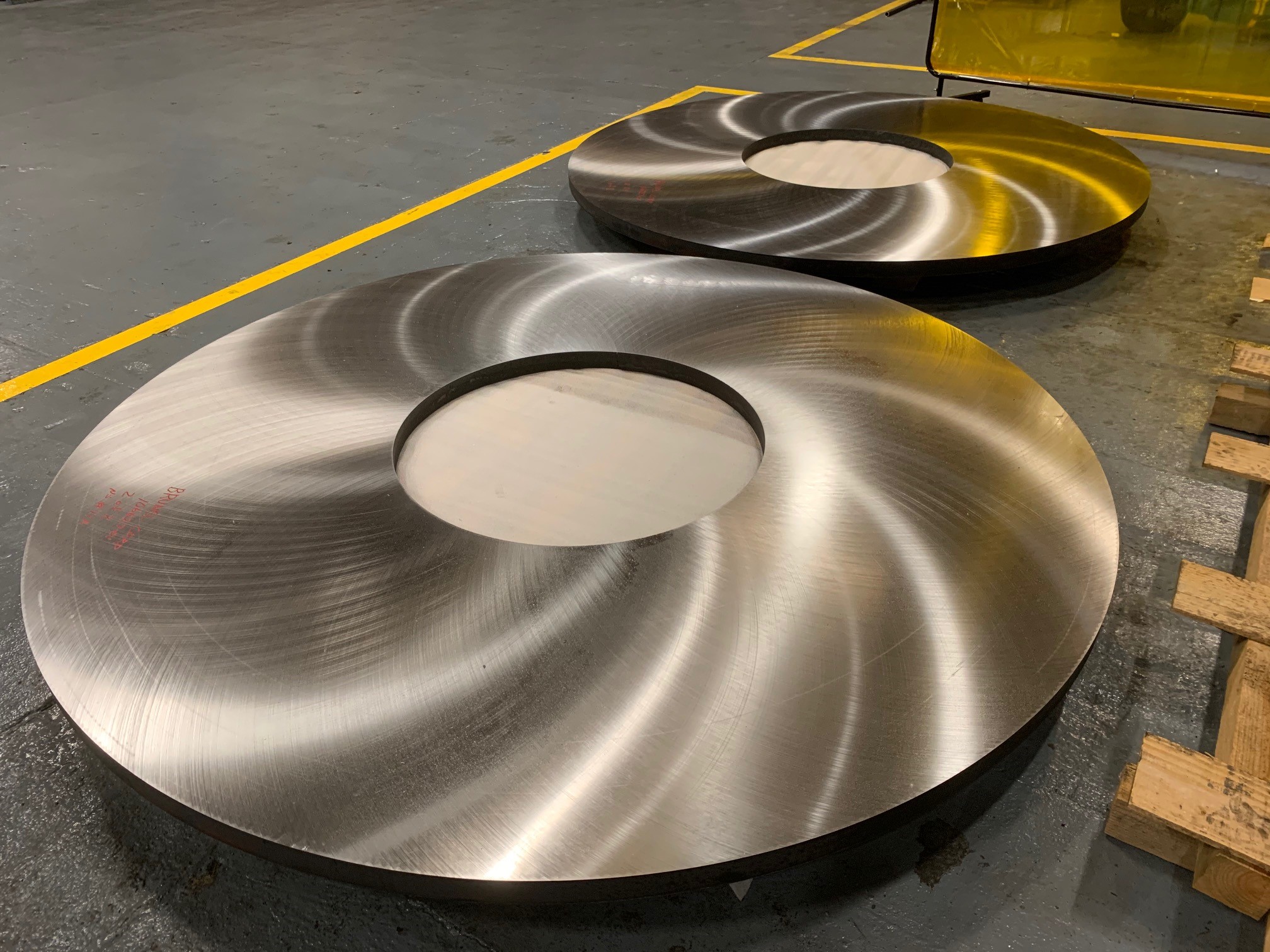

- Komplexe Geometrien durch mehrachsige Bearbeitung erreicht werden kann

- Flexible Prototypenerstellung und Produktion Fähigkeiten unter einem Dach

End-to-End-CNC-Lösungen für Innovationen in der Automobilindustrie

Jedes Fahrzeug ist ein System aus voneinander abhängigen Teilen, und wir bearbeiten viele der wichtigsten Teile. Yicen Precision arbeitet in jeder Phase der Automobilentwicklung, von der Forschung und Entwicklung bis zur Großserienproduktion, und bietet reaktionsschnelle, hochpräzise Lösungen.

Hochpräzise kundenspezifische Automobilteile

Ganz gleich, ob Sie ein Elektrofahrzeug der nächsten Generation entwickeln oder ein Leistungspaket fein abstimmen wollen, Komponenten von der Stange sind oft nicht ausreichend. Deshalb haben wir uns auf maßgeschneiderte Teile spezialisiert, die genau Ihren Anforderungen entsprechen.

Zu den üblichen Anwendungen gehören:

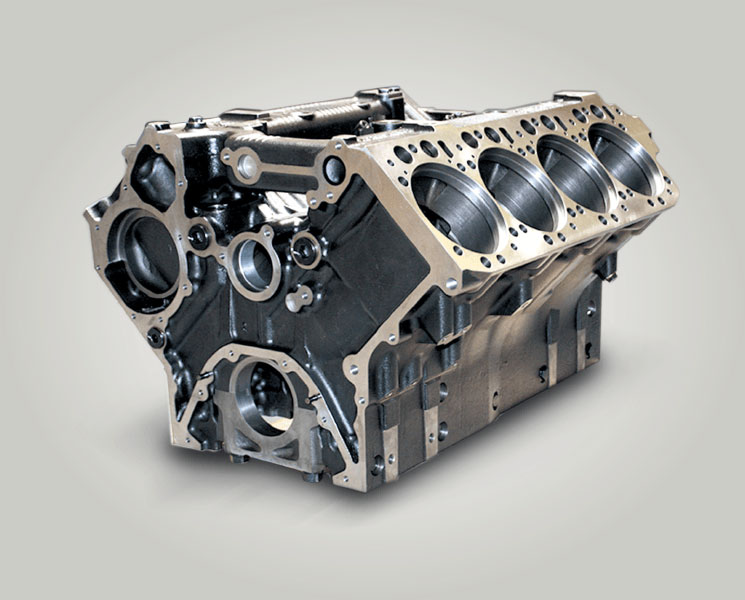

- Zylinderköpfe, Halterungen und Ventildeckel

- Querlenker und Gestänge

- Getriebegehäuse und Wellen des Antriebsstrangs

- Bremssattelhalterungen und Pedalteile

- Sensorgehäuse und kundenspezifische Steuerschränke

- Aftermarket-Upgrades für den Motorsport oder Luxusausstattungen

Unsere Kombination aus CNC-Fräsen, Drehen, Drahterodieren und Oberflächenbearbeitung ermöglicht es uns, Automobilteile zu liefern, die sowohl strukturelle als auch kosmetische Anforderungen erfüllen.

Beschleunigung der Forschung und Entwicklung in der Automobilindustrie durch schnelles CNC-Prototyping

Im Automobilsektor ist die Geschwindigkeit der Validierung entscheidend. Yicen Precision unterstützt die schnelle Entwicklung mit schnell zu fertigenden CNC-Prototypen, die den Ingenieuren helfen, Passform, Form und Funktion frühzeitig im Produktzyklus zu testen.

Zu den prototypischen Anwendungen gehören:

- EV-Batterieablagen und Kühlplatten

- Leichte Aluminium-Halterungen und -Gehäuse

- Modelle des Motorluftstroms oder des Abgassystems

- Montage- und Schnittstellenhardware für Sensoren oder Aktoren

Dank unserer internen DFM-Anleitung und unserer Bearbeitungsexpertise reduzieren wir die Komplexität der Konstruktion und unterstützen Sie bei schnellen Iterationen ohne Qualitätseinbußen.

CNC-Produktionsbearbeitung im Maßstab

Wenn Sie bereit sind zu skalieren, ist Yicen Precision bereit zu liefern. Wir bieten eine zuverlässige Produktionsbearbeitung, die durch robuste Qualitätskontrollen und wiederholbare Aufbauten unterstützt wird. Ob 250 Bremsenhalterungen oder 10.000 Elektromotorenflansche, wir helfen Ihnen, die Nachfrage pünktlich und innerhalb der Spezifikationen zu erfüllen.

Die Produktionsmöglichkeiten umfassen:

- 3- und 5-Achs-Fräsen für Präzisionsflächen und Ausschnitte

- CNC-Drehen für Wellen, Buchsen und symmetrische Teile

- Mehrteilige Bearbeitungsstrategien zur Minimierung von Ausfallzeiten

- Automatisierte Inspektion und serialisierte Rückverfolgung für QC

Reverse Engineering Brückenschlag zwischen Vergangenheit und Gegenwart

Innovation in der Automobilindustrie bedeutet nicht immer, bei Null anzufangen. Für alte Systeme, abgekündigte Komponenten oder Aftermarket-Projekte bietet Yicen Precision Reverse-Engineering-Dienstleistungen an, um schwer zu beschaffende Teile mit moderner Präzision nachzubauen.

Ideal für:

- Restaurierung von Oldtimern und Klassikern

- Kundenspezifisches Tuning und Leistungsverbesserungen

- Fuhrparkwartung für Nutz- oder Industriefahrzeuge

- Kleinserienfertigung für seltene oder veraltete Teile

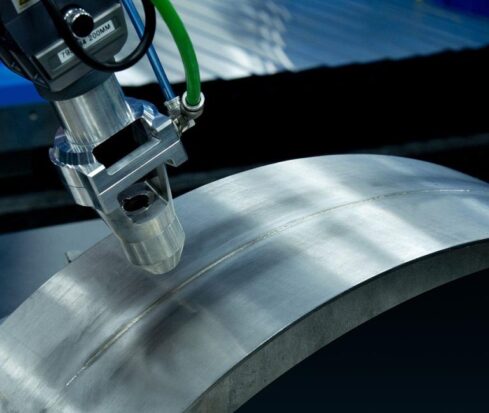

Mithilfe von 3D-Scans und CAD-Modellen erstellen wir exakte digitale Replikate und produzieren funktionale Ersatzteile, die oft haltbarer sind als die Originale.

Erfüllung der strengen Anforderungen der Automobilherstellung

Wenn die Straße unnachgiebig ist, müssen die Teile einwandfrei sein. Aus diesem Grund investiert Yicen Precision in strenge Qualitätssicherungsprozesse, die den Erwartungen der Automobilindustrie entsprechen.

Unsere QC-Maßnahmen umfassen:

- Erste-Artikel-Prüfung (FAI)

- Berichte über Koordinatenmessmaschinen (CMM)

- In-Prozess- und Endkontrolle von Teilen

- Vollständige Materialrückverfolgbarkeit und Zertifizierungen

- ISO-konforme Dokumentationspakete

Wir sind stolz darauf, Teile zu liefern, die nicht nur den Toleranzen entsprechen, sondern die Erwartungen übertreffen.

Warum Automobilkunden Yicen Precision vertrauen

Von Start-ups, die EV-Plattformen entwickeln, bis hin zu globalen OEMs, die Verbrennungsplattformen verfeinern, ist Yicen Precision ein bewährter Partner für Präzisionskomponenten. Hier erfahren Sie, warum man uns in der schnelllebigen Welt der Automobilindustrie vertraut:

Geschwindigkeit und Flexibilität

Kurze Vorlaufzeiten, schnelle Durchlaufzeiten und die Fähigkeit, schnell umzuschwenken, insbesondere in frühen Phasen der Entwicklung oder bei plötzlichem Produktionsbedarf.

Technische Zusammenarbeit

Unsere erfahrenen Ingenieure bieten DFM-Unterstützung, CAD-Datei-Optimierung und Materialberatung, um sicherzustellen, dass Ihre Teile sowohl funktional als auch kosteneffektiv sind.

Skalierbare Kapazität

Klein anfangen und groß rauskommen - unsere Produktionssysteme wachsen mit Ihrem Projekt, egal ob Sie 50 oder 50.000 Teile benötigen.

Fortgeschrittene Bearbeitungskapazitäten

Wir unterstützen komplexe Projekte mit fortschrittlichen Dienstleistungen wie 5-Achsen-CNC, Drahterodieren, Tieflochbohren und mehrschichtiger Oberflächenbearbeitung.

Antrieb für Ihr nächstes Automobilprojekt mit Yicen Precision

Der Weg in die Zukunft erfordert bessere, intelligentere, leichtere, schnellere und stärkere Teile. Yicen Precision liefert die Präzision, die Sie brauchen, um mit Zuversicht voranzukommen. Ganz gleich, ob Sie das Transportwesen neu erfinden oder ein bewährtes Design verfeinern wollen, unsere CNC-Lösungen sind bereit, Sie bei der Innovation zu unterstützen.

Lassen Sie uns gemeinsam die Zukunft der Mobilität gestalten.