A. What Are Medical Electronics Enclosures?

Medical electronics enclosures are precision-engineered protective housings designed to safeguard electronic circuits, display systems, power supplies, and control interfaces within medical devices while ensuring patient and operator safety. These critical enclosures include patient monitor housings, portable ultrasound scanner cases, infusion pump controllers, ventilator electronic assemblies, defibrillator chassis, laboratory instrument housings, surgical power console enclosures, and handheld diagnostic device casings. Used across hospitals, clinics, emergency response vehicles, and home healthcare settings, medical electronics enclosures must provide electromagnetic interference (EMI/RFI) shielding preventing device malfunction and interference with other equipment, physical protection against impact and environmental contamination, proper thermal management for electronic component reliability, and ergonomic user interfaces meeting human factors requirements. Precision CNC machining delivers the tight tolerances, seamless shielding surfaces, and complex features required for regulatory compliance, electromagnetic compatibility, and long-term device reliability.

B. Wichtige technische Anforderungen

Medical electronics enclosures CNC machining requires tolerances of ±0.001″ to ±0.003″ to ensure proper fit of electronic assemblies, display panels, connector interfaces, and sealing gaskets. Material specifications depend on shielding requirements, environmental conditions, and portability needs—aluminum alloys provide 60-100 dB EMI attenuation and excellent thermal conductivity, stainless steel offers superior durability for surgical environments requiring frequent disinfection, while engineered plastics enable electrical isolation for high-voltage components. Surface finish requirements range from Ra 32-63 microinch for internal mounting surfaces to Ra 16-32 microinch for external cosmetic areas, with options for hard anodizing, powder coating, or antimicrobial surface treatments.

Enclosures must meet IP rating requirements (typically IP42 to IP65) for dust and liquid ingress protection per IEC 60529, provide EMI/RFI shielding effectiveness of 40-80 dB across critical frequency ranges (150 kHz to 6 GHz) per CISPR 11/FCC Part 15, and incorporate proper grounding paths and bonding surfaces for safety compliance with IEC 60601-1. Thermal management features including ventilation slots, heat sink channels, internal ribbing for convection, and fan mounting provisions require precise machining. Wall thickness uniformity preventing warping (±0.005″), flatness of mating surfaces for gasket sealing (±0.002″), precise connector cutout positioning (±0.010″), and mounting boss locations with tight positional tolerance ensure reliable assembly and electromagnetic integrity.

C. Herausforderungen und Lösungen bei der Herstellung

Machining medical electronics enclosures presents complex challenges including maintaining uniform wall thickness on large, thin-walled housings without distortion, achieving precise cutout locations and dimensions for multiple connectors and interfaces, and producing continuous EMI shielding surfaces without gaps or surface discontinuities. Large enclosure dimensions combined with thin walls (1.5-3mm) create deflection during machining, while integrated features like internal mounting bosses, cable routing channels, and snap-fit assemblies demand multi-axis access and programming complexity. Surface preparation for EMI shielding requires defect-free finishes preventing electrical discontinuities.

Yicen Precision addresses these manufacturing challenges through strategic 5-axis simultaneous CNC machining minimizing setups and maintaining consistent work coordinate systems, advanced CAM programming with adaptive toolpaths controlling cutting forces and preventing thin-wall deflection, and custom fixturing designed specifically for large medical enclosures distributing clamping forces uniformly. Our high-speed machining centers with balanced spindles deliver excellent surface finishes while maintaining productivity. For thin-walled sections, we employ climb milling strategies, shallow depth-of-cut parameters, and high-feed low-radial-engagement toolpaths.

Quality control measures include coordinate measuring machine (CMM) inspection for critical interface dimensions and connector cutout positioning, surface plate inspection for mating surface flatness, EMI shielding continuity testing using specialized conductivity measurement, and functional assembly verification with electronic boards and displays. We provide first article inspection reports (FAIR) with complete dimensional analysis, geometric dimensioning and tolerancing (GD&T) verification, and maintain statistical process control monitoring for production batches. Contact us for specialized engineering consultation on your medical electronics enclosure manufacturing needs.

D. Anwendungen und Anwendungsfälle

Precision-machined medical electronics enclosures protect critical devices across diverse healthcare applications:

- Patient Monitoring Systems: Bedside vital signs monitor housings, multi-parameter monitor chassis, telemetry transmitter enclosures, and continuous monitoring device cases

- Portable Diagnostic Devices: Handheld ultrasound scanner housings, portable ECG recorder cases, point-of-care analyzer enclosures, and mobile diagnostic equipment chassis

- Therapeutic Equipment: Infusion pump controller housings, ventilator electronic enclosures, defibrillator chassis, electrosurgical generator cases, and oxygen concentrator electronics housings

- Laboratory Analyzers: Blood chemistry analyzer housings, hematology system enclosures, immunoassay analyzer chassis, and molecular diagnostic equipment cases

- Imaging Equipment: Portable X-ray controller housings, ultrasound system electronics enclosures, endoscopy processor cases, and C-arm control panel housings

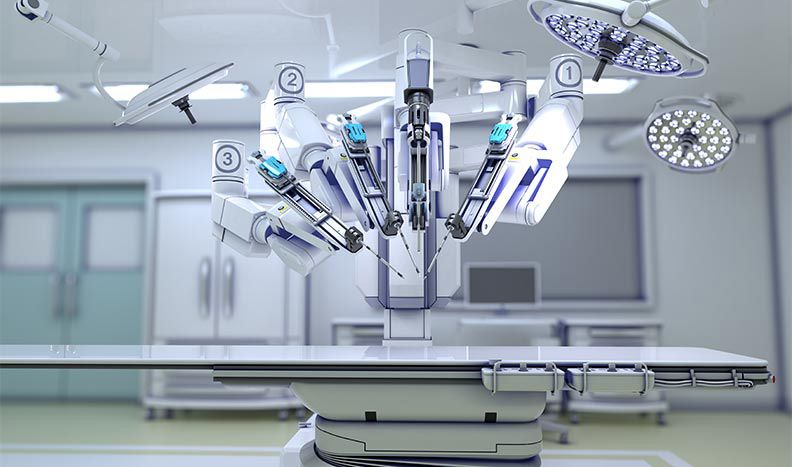

- Surgical Devices: Surgical robot controller enclosures, powered surgical instrument housings, laser system control boxes, and ablation generator chassis

- Home Healthcare Devices: Continuous glucose monitor housings, sleep apnea therapy device cases, home dialysis equipment enclosures, and remote patient monitoring electronics

E. Why Choose Yicen Precision for Medical Electronics Enclosures?

Yicen Precision brings extensive experience in medical electronics enclosures CNC machining with ISO 13485 certification and comprehensive understanding of IEC 60601-1 safety standards and IEC 60601-1-2 EMC requirements. Our rapid prototyping services deliver functional enclosure prototypes in 7-12 days, enabling design validation, EMC pre-compliance testing, thermal analysis, and human factors evaluation acceleration. We offer flexible production scaling from low-volume specialty equipment (10-50 units) to high-volume commercial manufacturing (1000+ units) with validated processes and consistent quality metrics.

Our engineering team provides Design for Manufacturability (DFM) consultation optimized for enclosure production efficiency, EMI/RFI shielding effectiveness analysis and design recommendations, thermal management optimization including computational fluid dynamics (CFD) support, and material selection guidance balancing shielding performance, weight, durability, and cost objectives. We coordinate comprehensive secondary operations including Type II or Type III anodizing for corrosion resistance and EMI shielding enhancement, conductive coating application for plastic enclosures requiring shielding, powder coating for durable scratch-resistant finishes, laser marking and pad printing for regulatory labeling and branding, ultrasonic cleaning for contamination-free assembly, and complete assembly services integrating gaskets, displays, connectors, and electronic boards.

Complete documentation includes dimensional inspection reports with GD&T verification, material certifications and test reports, surface treatment validation and coating thickness verification, EMI shielding effectiveness test data, and certificates of conformance supporting regulatory submissions (FDA 510(k), CE marking technical files). We maintain cost-effective medical electronics enclosures manufacturing through optimized machining strategies for large parts, efficient material nesting minimizing waste, and streamlined production workflows—delivering protective enclosures that meet medical device safety and EMC standards without premium pricing. Request your detailed engineering consultation and manufacturing quote for precision medical electronics enclosures today.