私たちは、試作品の迅速な製作と少量ロットのCNC生産を提供し、エネルギー・イノベーターが新しい設計をテストし、コンセプトから配備まで迅速に進めることを可能にします。

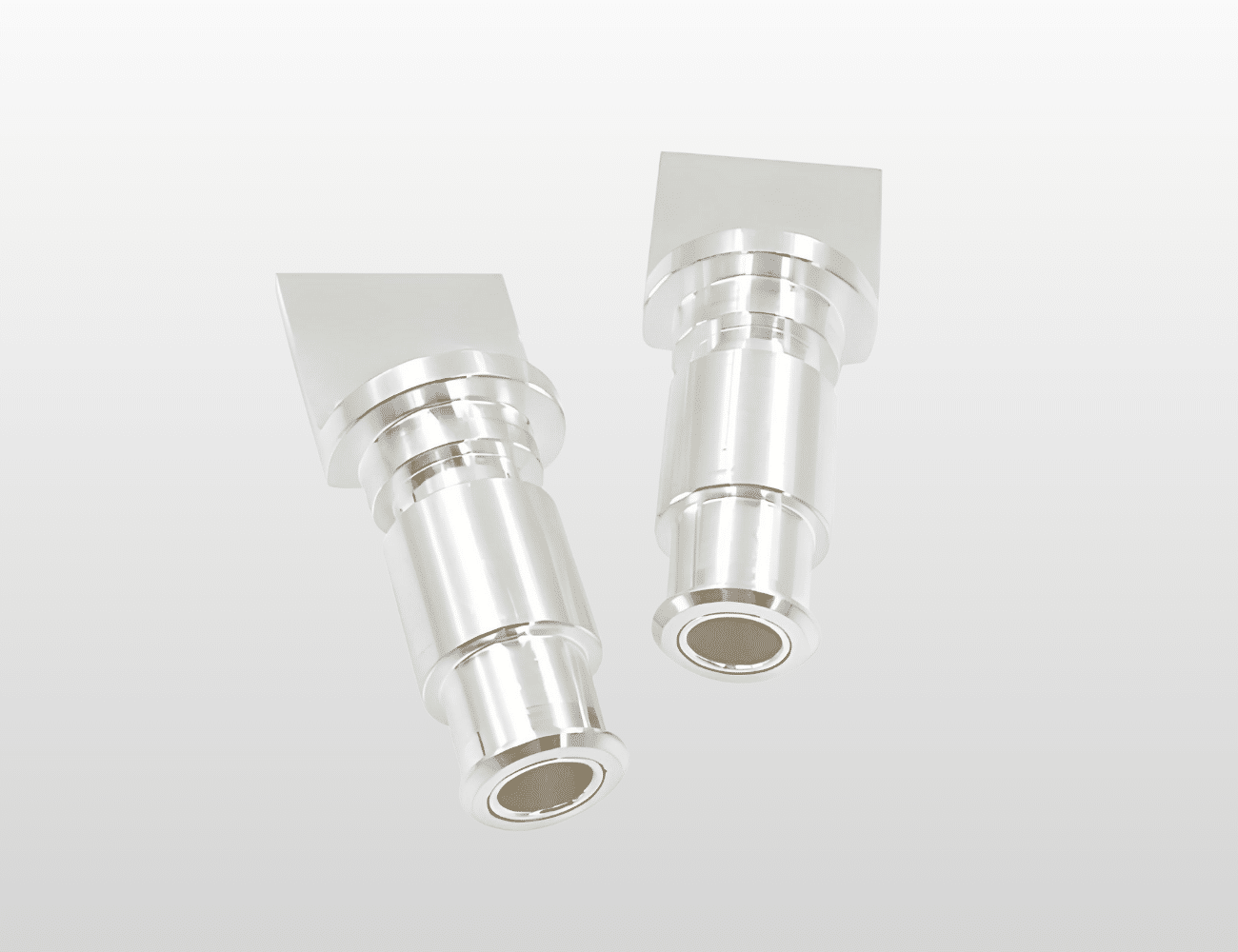

High-precision energy storage connectors engineered for safe, reliable electrical connections in battery systems and power storage applications. Our advanced CNC machining delivers connectors with optimized contact geometries, minimal resistance, and robust mechanical strength that ensure efficient power transfer and operational safety. Get custom connector solutions for your energy storage project today.

クリーンで再生可能なエネルギーへの移行には、過酷な条件に耐え、安定した性能を発揮する部品が必要です。 イーセン精密 は、風力発電、太陽光発電、エネルギー貯蔵システム用に設計されたCNC機械加工部品を提供することで、このミッションにおいて重要な役割を果たしています。タービンハブからバッテリーケーシングまで、当社の機械加工の専門知識は、強度、耐久性、完璧な統合を保証し、エネルギー革新者が自信を持って前進できるよう支援します。

Energy storage connectors provide the critical electrical interface between battery cells, modules, and packs in renewable energy systems, delivering low-resistance current pathways while incorporating safety features including mechanical interlocks, arc suppression, and quick-disconnect capabilities for maintenance and emergency isolation. These connectors must handle high continuous currents and transient loads while maintaining contact integrity through thousands of connection cycles and exposure to temperature extremes and vibration.

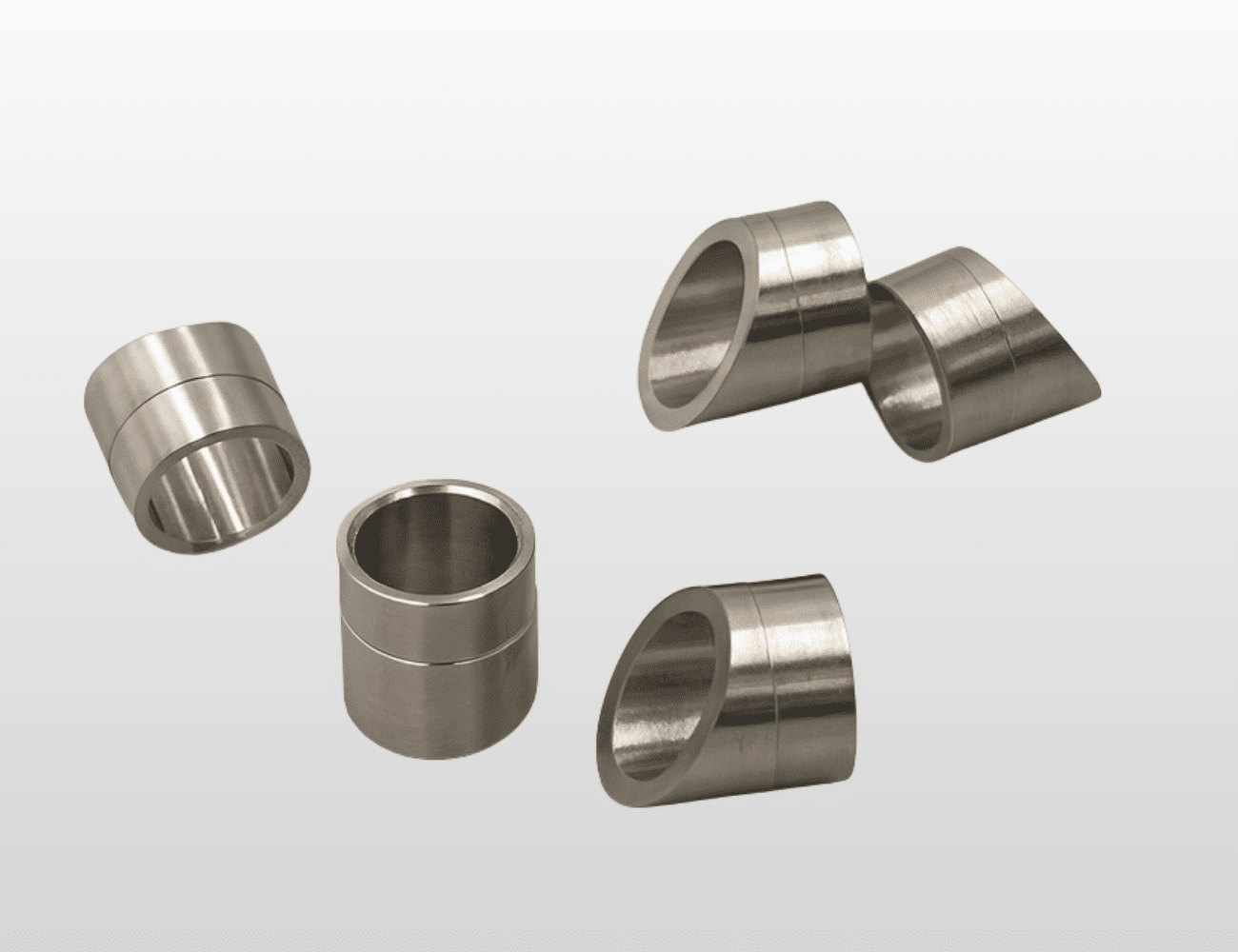

易岑精密は、専門化された energy storage connectors CNC machining through our precision 3-axis, 4-axis, and 5-axis milling centers combined with Swiss-style turning capabilities for complex connector geometries requiring tight tolerances on contact surfaces and mechanical features. We machine energy storage connectors from copper alloys C101, C110, and tellurium copper C145, aluminum alloys 6061-T6 and 6101-T6 for lightweight bus bar applications, and stainless steel 304 and 316 for structural components, maintaining contact surface tolerances within ±0.002″ and thread specifications per ANSI 2A/2B standards. Our ISO 9001 and AS9100-compliant manufacturing processes incorporate contact resistance testing, mechanical cycling validation, and dimensional verification to ensure every energy storage connector meets demanding specifications for current-carrying capacity, voltage isolation, and mechanical reliability in residential battery systems, commercial energy storage installations, utility-scale battery farms, and electric vehicle charging infrastructure.

風力発電や太陽光発電から高度なバッテリー技術に至るまで、再生可能エネルギーシステム向けに高性能なCNC部品を設計し、耐久性と持続可能性を追求しています。

高度な技術と比類のない効率性を備えた高精度CNC製造。

最新鋭の機械を使用した合理化されたCNC生産により、安定した品質を実現。

複雑なCNC部品の専門的な加工と組み立てを一箇所で行うことができます。.

完全自動化されたCNCオペレーションにより、高速、高精度、高信頼性の加工を実現。

最高品質のCNCパーツをスピードと精度で提供するために最適化されています。

シームレスなワークフローと優れた結果をもたらすエンドツーエンドのCNC製造。

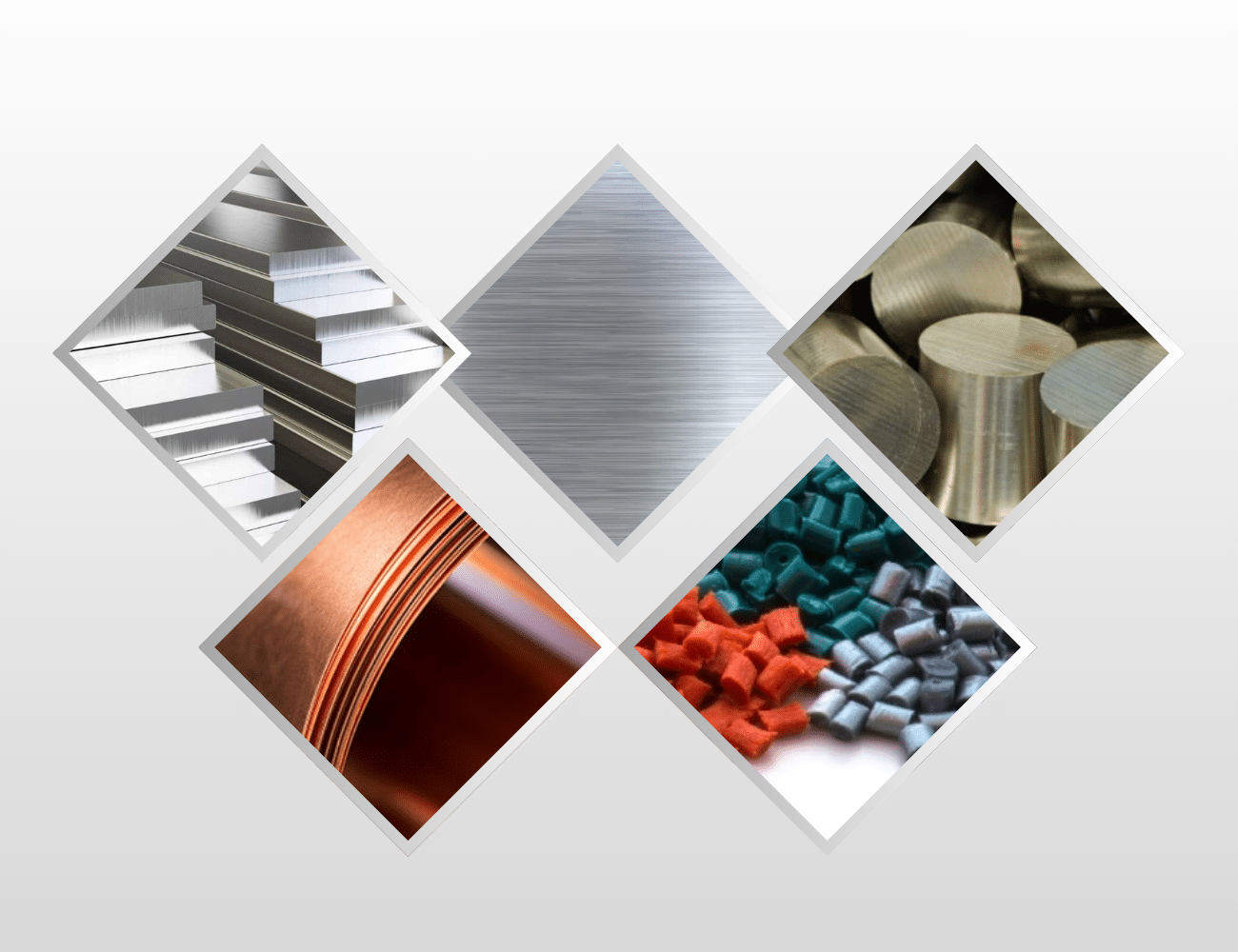

Yicen Precisionは、風力発電、太陽光発電、エネルギー貯蔵システムの構造、耐熱性、耐薬品性の要求を満たすために、耐久性のある金属と高度な複合材を幅広く取り揃えています。

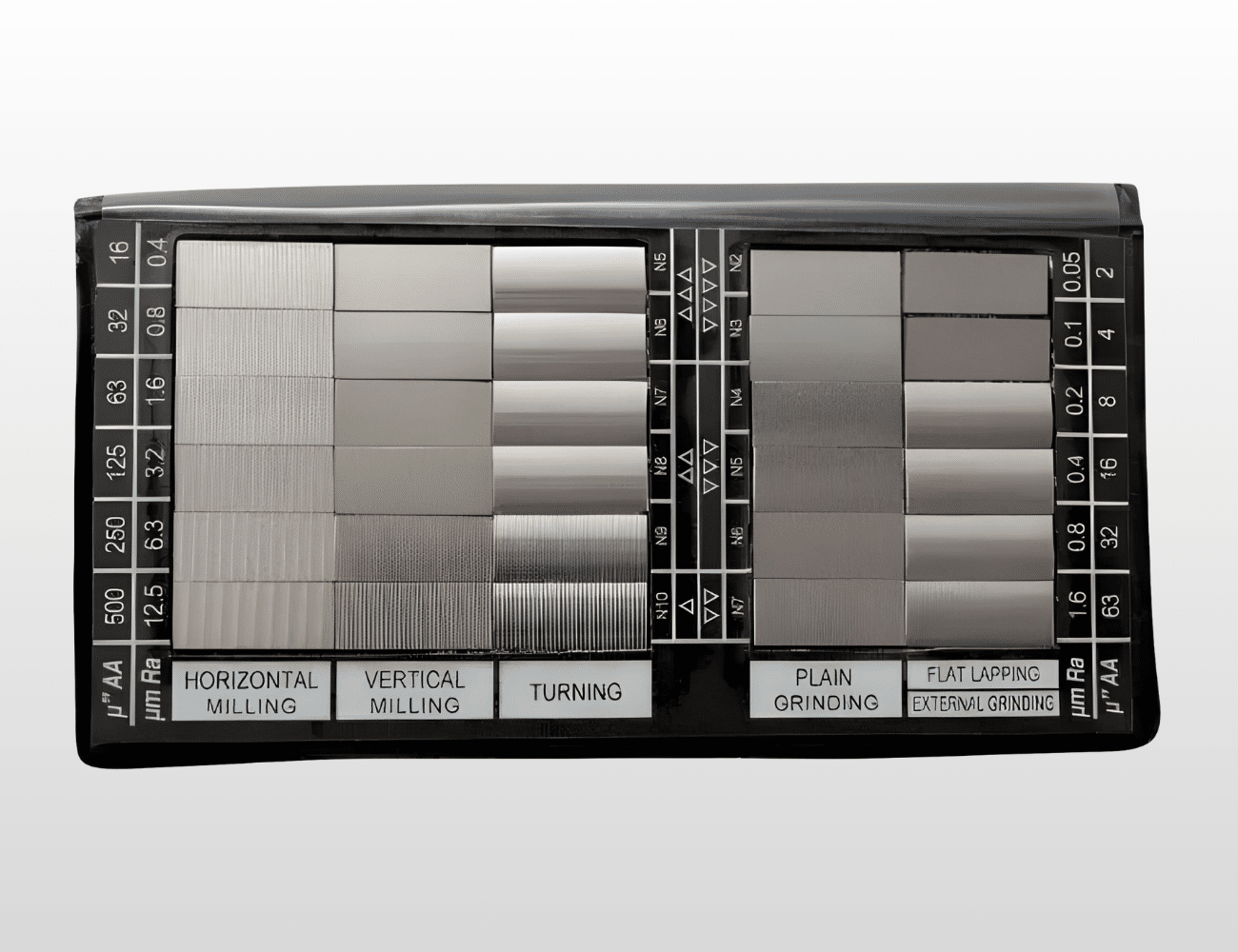

再生可能エネルギーシステムの表面仕上げは、耐食性、耐摩耗性、過酷な環境下での長期信頼性を確保する必要があります。Yicen Precisionは、風力発電、太陽光発電、バッテリーの用途で使用される部品の寿命を延ばす保護コーティングと機能性コーティングを施します。

お客様がYicen PrecisionのCNC加工に信頼を寄せる理由をご覧ください。私たちの声は、精度、品質、納期厳守、献身的なサポートへの満足を強調し、世界中の業界全体で永続的なパートナーシップを育んでいます。

Yicen Precisionは、トップクラスのCNC機械加工サービスを提供してくれました。彼らの細部への配慮と効率性は比類のないものです。

迅速な納期と精密な加工。Yicen Precisionは、常に時間通りに高品質の仕事をお届けします。

卓越したサービスと信頼できる加工。Yicen PrecisionはすべてのCNC関連プロジェクトのための私達の頼れるサプライヤーです。

素晴らしいコミュニケーションと優れた職人技。Yicen Precisionは常に私たちの厳しい仕様を満たしています。

私たちは、お客様のアイデアを比類のないスピードと精度で、高品質で機能的な部品に変換することを専門としています。高度な技術と熟練した職人技で、最も複雑な仕様を満たす部品を作り出します。

Energy storage connectors are engineered electrical components that establish and maintain conductive pathways between battery cells, modules, busbars, and power conversion equipment in energy storage systems, incorporating contact interfaces, mechanical retention features, and safety mechanisms. These connectors function as the critical junctions enabling series and parallel battery configurations while providing serviceable connections for maintenance, testing, and emergency isolation. They are essential in lithium-ion battery packs for residential and commercial installations (5-500 kWh), utility-scale battery energy storage systems (1+ MWh), electric vehicle fast charging stations, microgrid energy storage, backup power systems, and renewable energy integration applications. The connector’s electrical and mechanical performance directly influences system efficiency through contact resistance losses, reliability through connection integrity under vibration and thermal cycling, and safety through proper current interruption and arc suppression capabilities.

Energy storage connectors CNC machining requires maintaining contact surface flatness within ±0.001″ and surface finish of 32 Ra or better to minimize contact resistance and ensure current distribution uniformity across mating interfaces. Material specifications typically demand high-conductivity copper alloys with minimum 95% IACS (International Annealed Copper Standard) conductivity, or aluminum alloys exceeding 61% IACS for weight-sensitive applications. Contact resistance must remain below 50 microhms for high-current applications (200+ amps) with voltage drop less than 50 mV at rated current. Mechanical requirements include retention forces exceeding 50 lbf to prevent accidental disconnection under vibration, with insertion/extraction forces optimized between 15-40 lbf for manual serviceability. Thread specifications for bolted connections follow Class 2A/2B tolerances with thread engagement depths calculated per ASME B1.1 standards to prevent galling and ensure torque retention. Temperature rise limits typically specify maximum 30°C above ambient at rated continuous current, requiring thermal design optimization. Plating specifications often require silver plating (0.0002-0.0005″ thickness) or tin plating (0.0002-0.0003″ thickness) for enhanced contact conductivity and corrosion protection, applied per ASTM B700 and MIL-DTL-45204 standards.

プロデュース energy storage connectors presents significant challenges including achieving the tight tolerances and superior surface finishes required on contact surfaces while working with soft, gummy copper alloys that tend to produce built-up edge and poor surface quality. The combination of high-current-carrying requirements demanding substantial cross-sectional areas with compact packaging constraints requires complex geometries with thin-wall features and deep cavities. Energy storage connector manufacturing also faces difficulties in maintaining dimensional stability during plating operations, preventing galvanic corrosion between dissimilar materials in multi-metal assemblies, and achieving consistent thread quality for reliable bolted connections carrying high currents.

Yicen Precision overcomes these challenges through strategic tooling selection including PCD (polycrystalline diamond) and ultra-sharp carbide tools that produce superior surface finishes on copper alloys without built-up edge formation, achieving 16-32 Ra surface finishes that minimize contact resistance. Our machining strategies incorporate high-speed, low-force cutting parameters with optimized chip evacuation that prevent work hardening and dimensional distortion in soft copper materials. For complex connector geometries, our 5-axis machining centers enable single-setup production that eliminates alignment errors from multiple operations while reducing cycle times by 25-35%. We employ specialized thread milling and thread forming operations that produce Class 2A threads with superior strength and surface finish compared to conventional tapping, critical for bolted connections experiencing thermal cycling. Climate-controlled manufacturing environments maintain temperature stability within ±2°F, ensuring dimensional consistency during precision operations on thermally sensitive materials. Quality control protocols include four-wire Kelvin resistance measurement verifying contact resistance below specification limits, CMM verification of all critical dimensions including contact surface flatness and parallelism, mechanical pull testing validating retention forces, and optical inspection confirming surface finish quality. We coordinate with certified plating suppliers who provide controlled-thickness deposits with adhesion testing per ASTM B571, and incorporate post-plating dimensional verification to ensure plating buildup remains within tolerance envelopes.

Energy storage connectors CNC machining serves critical applications across battery and power storage systems:

私たちの専門知識 precision energy storage connector manufacturing combines advanced machining capabilities with comprehensive understanding of electrical contact physics, thermal management, and high-current applications. We maintain production capacity ranging from small-format cell-level connectors to large bus bar assemblies handling 2000+ amps, with Swiss turning capabilities for miniature precision connectors and heavy-duty machining centers for substantial power distribution components. Fast turnaround times of 2-4 weeks for production quantities support rapid product development and market introduction, while our rapid prototyping services deliver functional connectors within 5-7 business days for electrical testing, mechanical validation, and design iteration. Our engineering team provides comprehensive DFM consultation, optimizing connector geometries to minimize contact resistance through increased contact area and pressure distribution, reduce material costs through efficient nesting and material selection, and enhance thermal performance through strategic mass distribution and surface area optimization. We collaborate on material selection, balancing electrical conductivity requirements with mechanical strength needs, corrosion resistance, weight constraints, and total system costs. We provide integrated solutions including plating specification development, torque specification calculations based on joint analysis, and thermal modeling predicting temperature rise under various load profiles. Complete material traceability documentation accompanies every shipment, including mill certifications with conductivity data, dimensional inspection reports, contact resistance test results, mechanical pull test data, and plating thickness verification. We deliver cost-effective solutions through strategic copper procurement that reduces raw material costs by 12-18%, efficient machining strategies that minimize material waste and cycle times, and quality systems ensuring zero-defect contact performance—providing reliable electrical connections that minimize power losses, withstand demanding mechanical and thermal environments, and deliver decades of maintenance-free operation in critical energy storage applications from residential backup systems to utility-scale renewable energy integration installations.

エクスペリエンス 機械加工サービス ブログでは、CNC加工、業界動向、製造のヒント、技術の最新情報など、専門家の見識をご紹介しています。

易岑精密は新エネルギーの急速な革新にどのように貢献していますか。

私たちは、試作品の迅速な製作と少量ロットのCNC生産を提供し、エネルギー・イノベーターが新しい設計をテストし、コンセプトから配備まで迅速に進めることを可能にします。

CNC部品はハイブリッド・エネルギー・システムに適応できますか?

CNC機械加工は、ソーラー+蓄電池のようなハイブリッドセットアップ用の部品のカスタマイズを可能にし、多様なエネルギー技術間の互換性を保証する。

CNC加工は再生可能システムのメンテナンスコストをどのように削減するか?

耐久性と耐腐食性に優れた部品を製造することで、CNC機械加工は摩耗や損傷を最小限に抑え、風力発電や太陽光発電システムの修理頻度とコストを低減する。

CNC加工は水素および燃料電池技術をサポートできるか?

そう、CNCは、精度がエネルギー出力と安全性に直結する水素燃料電池の精密フロープレート、マニホールド、コネクターの製造に最適なのだ。