A. What is Medical Device Prototyping?

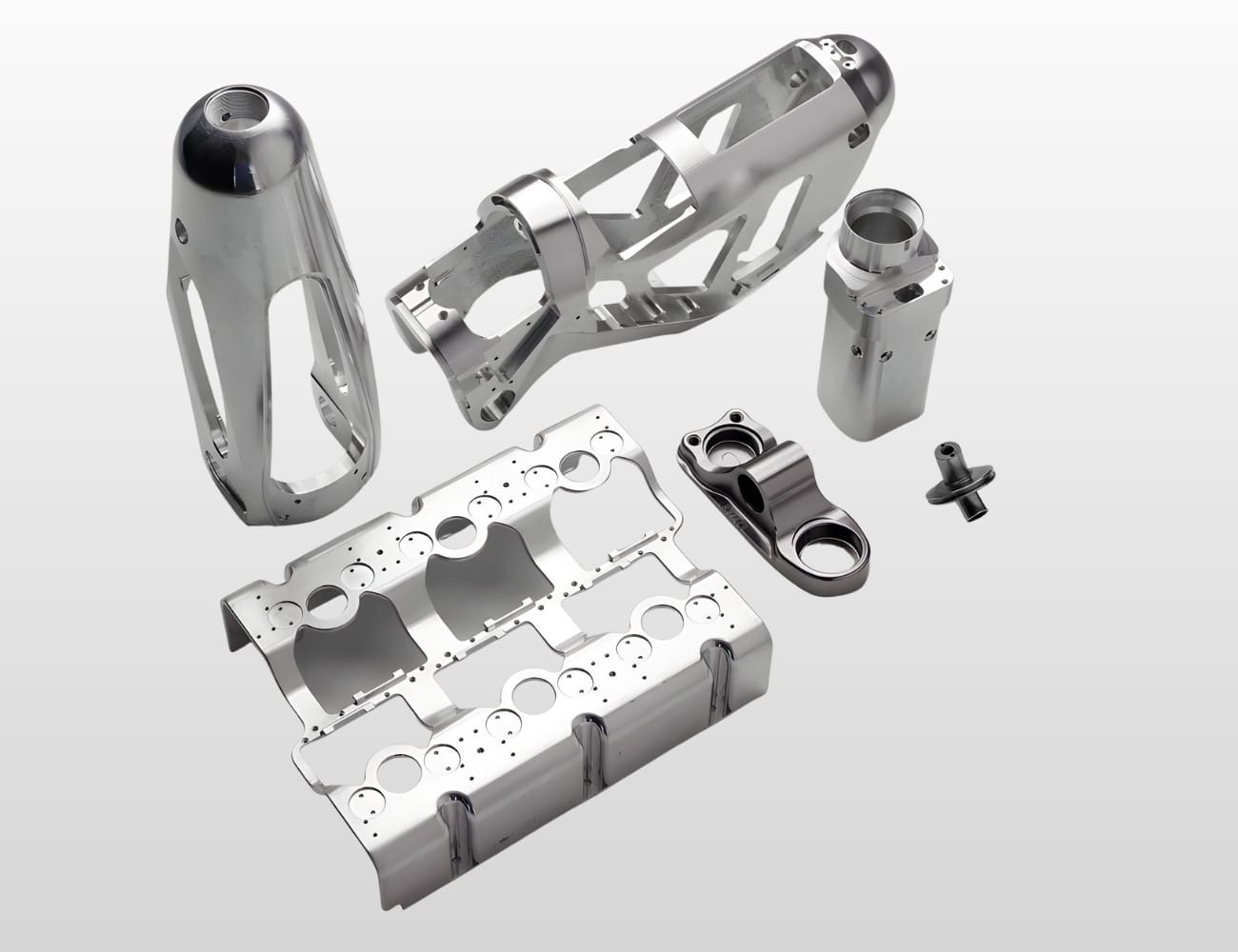

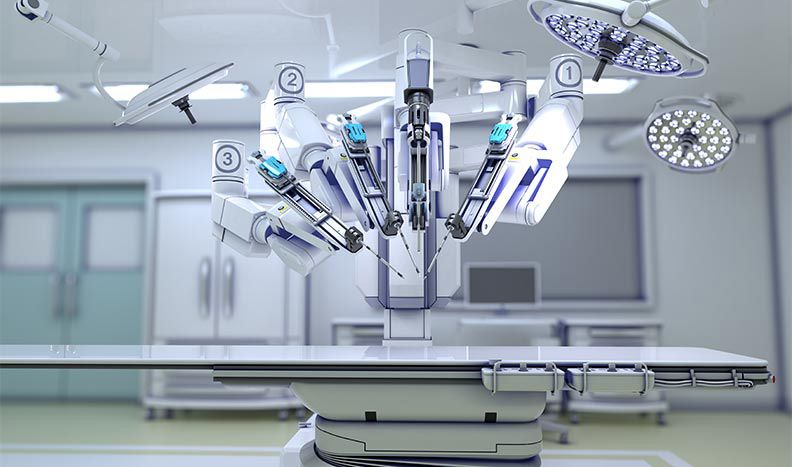

Medical device prototyping is the critical development phase where conceptual designs are transformed into physical, functional models for design verification, validation testing, and regulatory preparation. These prototype medical devices include orthopedic implant models for biomechanical testing, surgical instrument prototypes for ergonomic evaluation, diagnostic device components for performance validation, drug delivery system prototypes for dose accuracy testing, medical equipment housings for fit and functional assessment, and implantable component prototypes for biocompatibility studies. Used by medical device startups, R&D departments, university research labs, and established manufacturers, prototyping enables iterative design refinement, clinical evaluation preparation, investor demonstrations, and FDA submission support. Precision CNC machining prototyping delivers production-equivalent materials, dimensional accuracy, and surface finishes allowing authentic performance testing, reducing development risks, and accelerating time-to-market while maintaining the quality standards required for medical device applications.

B.主な技術要件

Medical device prototyping CNC machining requires the same demanding tolerances as production parts—typically ±0.0002″ to ±0.005″ depending on component function—to ensure prototype testing accurately predicts production performance. Material specifications must match intended production materials including certified biocompatible alloys (Ti-6Al-4V ELI per ASTM F136, CoCrMo per ASTM F1537, 316LVM per ASTM F138) for implantable prototypes requiring biocompatibility testing, or equivalent-grade materials for non-implant prototypes. Surface finish requirements mirror production specifications: Ra 4-16 microinch for optical or bearing surfaces, Ra 32-125 microinch for bone-contacting implant surfaces, or Ra 16-32 microinch for cosmetic external surfaces.

Prototypes must accurately represent critical features including complex geometries for fit testing, threaded connections for assembly validation, porous surfaces for osseointegration evaluation, and internal channels for fluid flow verification. Dimensional accuracy enables functional testing of articulation, mechanical strength, seal performance, and dose accuracy. Material certifications provide traceability for prototypes entering biocompatibility testing (ISO 10993), mechanical testing (tensile, fatigue, wear), or regulatory submissions. Speed without sacrificing accuracy is essential—typical turnaround requirements of 3-7 days for simple prototypes, 7-14 days for complex assemblies, enabling rapid design iteration cycles critical in competitive medical device markets.

C.製造上の課題と解決策

Prototyping medical devices presents unique challenges including balancing speed requirements with the precision and material quality demands of medical applications, producing small quantities (1-10 pieces) economically without dedicated production tooling, and maintaining flexibility for design iterations while ensuring dimensional consistency across prototype revisions. Complex geometries requiring multi-axis machining, thin-walled structures prone to deflection, and tight tolerances on small features demand careful programming and setup. Material costs for small quantities of certified biomedical alloys can be prohibitive without efficient material utilization strategies.

Yicen Precision addresses prototyping challenges through dedicated rapid prototyping workflows with expedited scheduling and prioritized machine access, extensive material inventory of certified biomedical alloys in various stock sizes minimizing lead times and material waste, and advanced 5-axis CNC capabilities enabling complex part production in minimal setups reducing turnaround time. Our experienced programming team rapidly generates optimized toolpaths from CAD files (STP, STEP, IGES formats) with design for manufacturability (DFM) feedback identifying potential issues before machining begins.

We employ efficient fixturing strategies for prototype quantities including modular tooling systems and soft jaws customized within hours rather than days. Quality verification uses the same CMM inspection, surface roughness measurement, and material certification processes as production parts, ensuring prototype test results accurately predict production performance. Our engineering team provides collaborative design support including DFM analysis, material selection consultation based on testing requirements, tolerance optimization balancing performance needs with manufacturing efficiency, and assembly planning for multi-component prototypes. Learn more about accelerating your medical device development with our rapid prototyping capabilities.

D.アプリケーションとユースケース

Precision-machined medical device prototypes support critical development phases across diverse applications:

- Design Verification Testing: Functional prototypes for dimensional verification, fit testing with mating components, assembly validation, and design iteration cycles

- Preclinical Performance Testing: Implant prototypes for biomechanical testing, fatigue analysis, and wear simulation; surgical instruments for ergonomic evaluation and cutting performance

- Biocompatibility Studies: ISO 10993-compliant prototypes manufactured from certified materials for cytotoxicity, sensitization, and implantation testing

- Clinical Evaluation: Prototypes for cadaver studies, surgical technique development, physician feedback sessions, and clinical trial preparation

- Regulatory Submissions: Production-equivalent prototypes supporting FDA 510(k) submissions, design history files (DHF), and technical documentation

- Investor Demonstrations: High-quality prototypes for funding presentations, trade show displays, and partnership discussions showcasing design intent

- Manufacturing Process Development: Prototypes for production tooling validation, assembly process refinement, and quality inspection procedure establishment

E. Why Choose Yicen Precision for Medical Device Prototyping?

Yicen Precision delivers specialized medical device prototyping CNC machining expertise with ISO 13485 certification ensuring quality system rigor even for prototype quantities. Our rapid turnaround commitment provides simple prototypes in 3-5 business days and complex multi-feature components in 7-10 days, significantly accelerating development timelines compared to typical 3-4 week prototype lead times. We maintain extensive inventory of certified biomedical materials including multiple titanium alloys, cobalt-chromium, stainless steel grades, PEEK, and specialty polymers enabling immediate project initiation without material procurement delays.

Our engineering collaboration includes complimentary Design for Manufacturability (DFM) review identifying potential manufacturing challenges and optimization opportunities before machining begins, material selection consultation matching materials to testing requirements and regulatory pathways, tolerance analysis ensuring critical features meet functional requirements while optimizing manufacturability, and assembly support for multi-component prototypes including fit verification and assembly documentation. We provide flexible iteration support with discounted pricing for design revisions, rapid re-quote turnaround (typically same day), and material credit programs when prototype materials can be reused for iterations.

Complete documentation supports your development process including dimensional inspection reports with actual measurements versus nominal specifications, material certifications with lot traceability for biocompatibility testing, surface finish verification data, certificates of conformance, and photography/documentation for design history files (DHF). Our prototype-to-production pathway ensures seamless transition with manufacturing process validation, production tooling development leveraging prototype learnings, and supply chain continuity maintaining the same quality standards and material sources. Cost-effective prototyping through efficient material utilization, optimized setup strategies, and streamlined workflows delivers production-quality prototypes at competitive pricing—typically 30-50% faster than industry standard lead times. Request your rapid quote and accelerate your medical device innovation today.