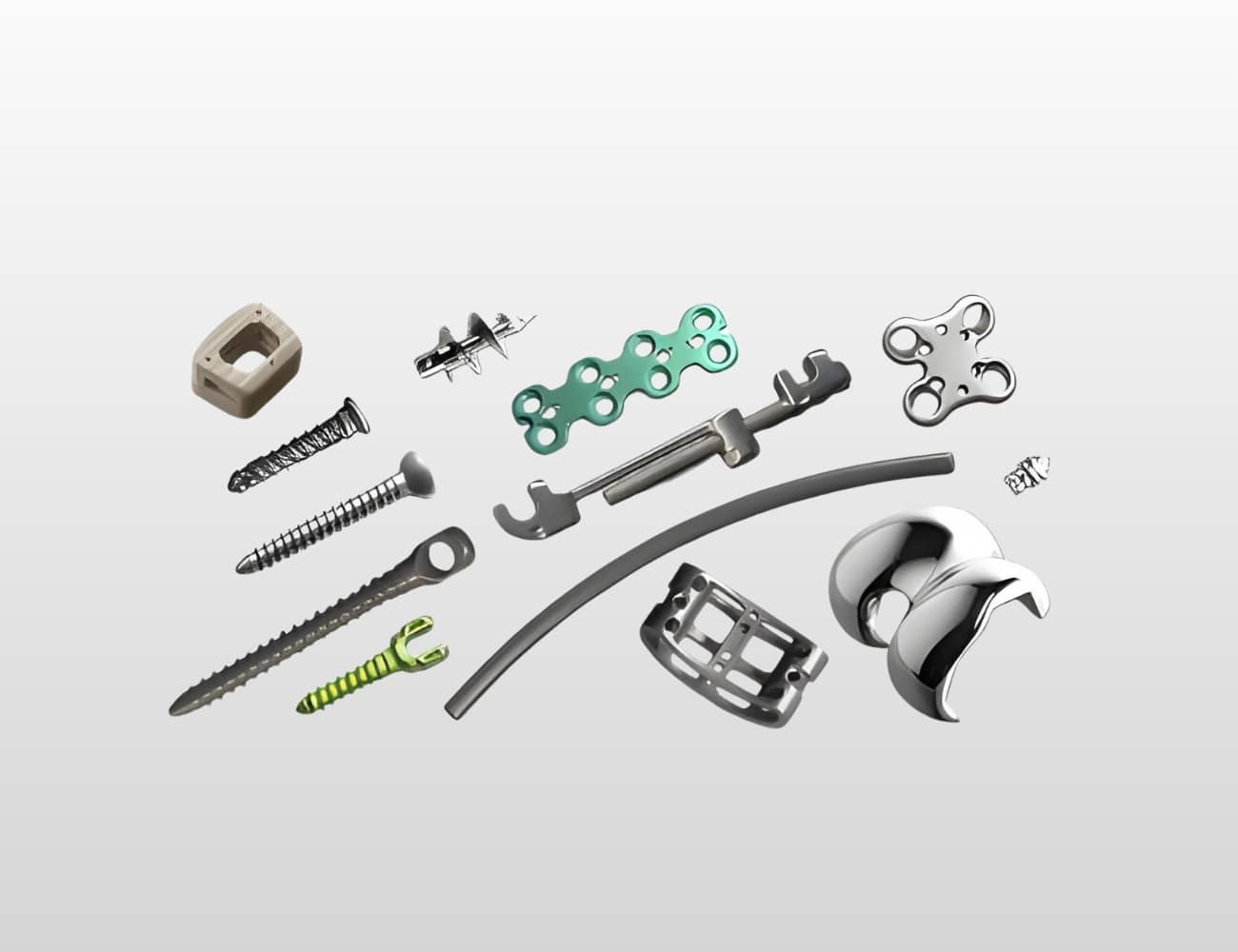

A. What Are Implantable Components?

Implantable components are medical devices designed for permanent or long-term placement within the human body to restore function, support healing, or monitor physiological conditions. These critical components include hip and knee joint replacements, spinal fusion cages and rods, dental implant fixtures, pacemaker and defibrillator housings, bone plates and screws, and neurostimulation electrodes. Used across orthopedic surgery, cardiology, neurology, and dental medicine, implantable components must demonstrate exceptional biocompatibility, mechanical strength, and corrosion resistance. Precision CNC machining ensures dimensional accuracy, optimal surface characteristics for tissue integration, and contamination-free production that meets the highest regulatory standards for patient safety.

B.主な技術要件

Implantable components CNC machining demands micro-tolerances of ±0.0002″ to ±0.0005″ to ensure proper fit, biomechanical alignment, and long-term stability within the body. Material specifications require certified biocompatible alloys with full traceability—typically Ti-6Al-4V ELI (Extra Low Interstitial) for orthopedic applications, CoCrMo for high-wear joint surfaces, or 316LVM stainless steel for temporary implants. Surface finish requirements range from Ra 32 microinch for bone-contacting surfaces promoting osseointegration to Ra 4-8 microinch for articulating surfaces minimizing wear debris. Components must withstand physiological loads, corrosive body fluids (chloride exposure), and temperature variations while maintaining structural integrity for 15-30 years. Thread accuracy, porous coating compatibility, and zero-defect surface quality are non-negotiable for patient safety.

C.製造上の課題と解決策

Machining implantable components presents extraordinary challenges including achieving micro-tolerances on complex anatomical geometries, maintaining surface integrity without subsurface damage, and preventing any contamination that could cause adverse biological reactions. Titanium’s work-hardening characteristics, thin-walled structures on spinal cages, and intricate porous surfaces for bone ingrowth demand specialized manufacturing strategies. Material removal must avoid heat-affected zones or microstructural changes that compromise biocompatibility or fatigue strength.

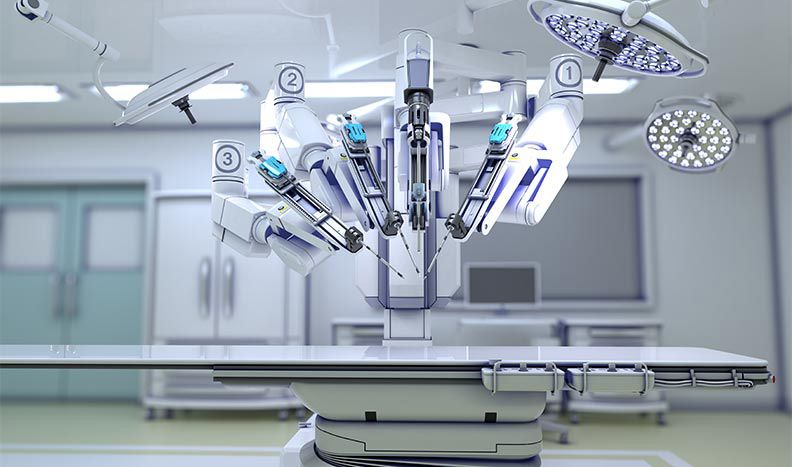

Yicen Precision addresses these challenges through dedicated 5-axis CNC machining with climate-controlled environments (±1°C), ultra-precision tooling with optimized cutting parameters for biomedical alloys, and advanced CAM programming that minimizes thermal input. Our cleanroom-adjacent manufacturing prevents particulate contamination during production. Quality assurance includes coordinate measuring machine (CMM) inspection with uncertainty analysis, surface roughness verification, non-destructive testing for subsurface defects, and comprehensive material certification documentation.

We maintain strict process validation protocols with statistical process control (SPC) monitoring and implement lot traceability systems tracking every component from raw material through final inspection. Learn more about our capabilities for your critical implant manufacturing needs.

D.アプリケーションとユースケース

Precision-machined implantable components serve life-changing functions across multiple medical specialties:

- Orthopedic Implants: Hip stems, femoral heads, tibial trays, acetabular cups, and custom joint replacement components

- Spinal Implants: Fusion cages, pedicle screws, spinal rods, interbody devices, and vertebral spacers

- Dental Implants: Titanium implant fixtures, abutments, healing caps, and prosthetic retention systems

- Cardiac Devices: Pacemaker and ICD housings, lead connectors, valve components, and stent delivery systems

- Trauma Fixation: Bone plates, intramedullary nails, compression screws, and fracture fixation hardware

- Neurostimulation Devices: Deep brain stimulation electrodes, spinal cord stimulator components, and cochlear implant parts

- Cranial and Maxillofacial: Skull plates, orbital floor implants, mandibular reconstruction components, and temporomandibular joint prostheses

E. Why Choose Yicen Precision for Implantable Components?

Yicen Precision delivers specialized expertise in implantable medical device manufacturing with ISO 13485 certification and deep understanding of FDA regulatory pathways (510(k), PMA). Our implantable components CNC machining services offer rapid prototype development with 5-7 day turnarounds, enabling accelerated design validation and clinical trial preparation. We provide scalable production from R&D quantities through commercial-scale manufacturing with validated processes and consistent quality metrics.

Our engineering support includes Design for Manufacturability (DFM) analysis optimized for implant performance, material selection guidance based on biomechanical requirements, and regulatory documentation assistance. Complete material traceability includes certified biocompatible materials with mill test reports, ASTM/ISO compliance certificates, and batch genealogy for regulatory submissions and post-market surveillance. We deliver cost-effective implant manufacturing through optimized cycle times, efficient material utilization, and streamlined inspection protocols—providing life-critical components without compromising safety or quality. Request your detailed technical consultation and quote for precision implantable components today.