A. What are Customized Fastening Solutions?

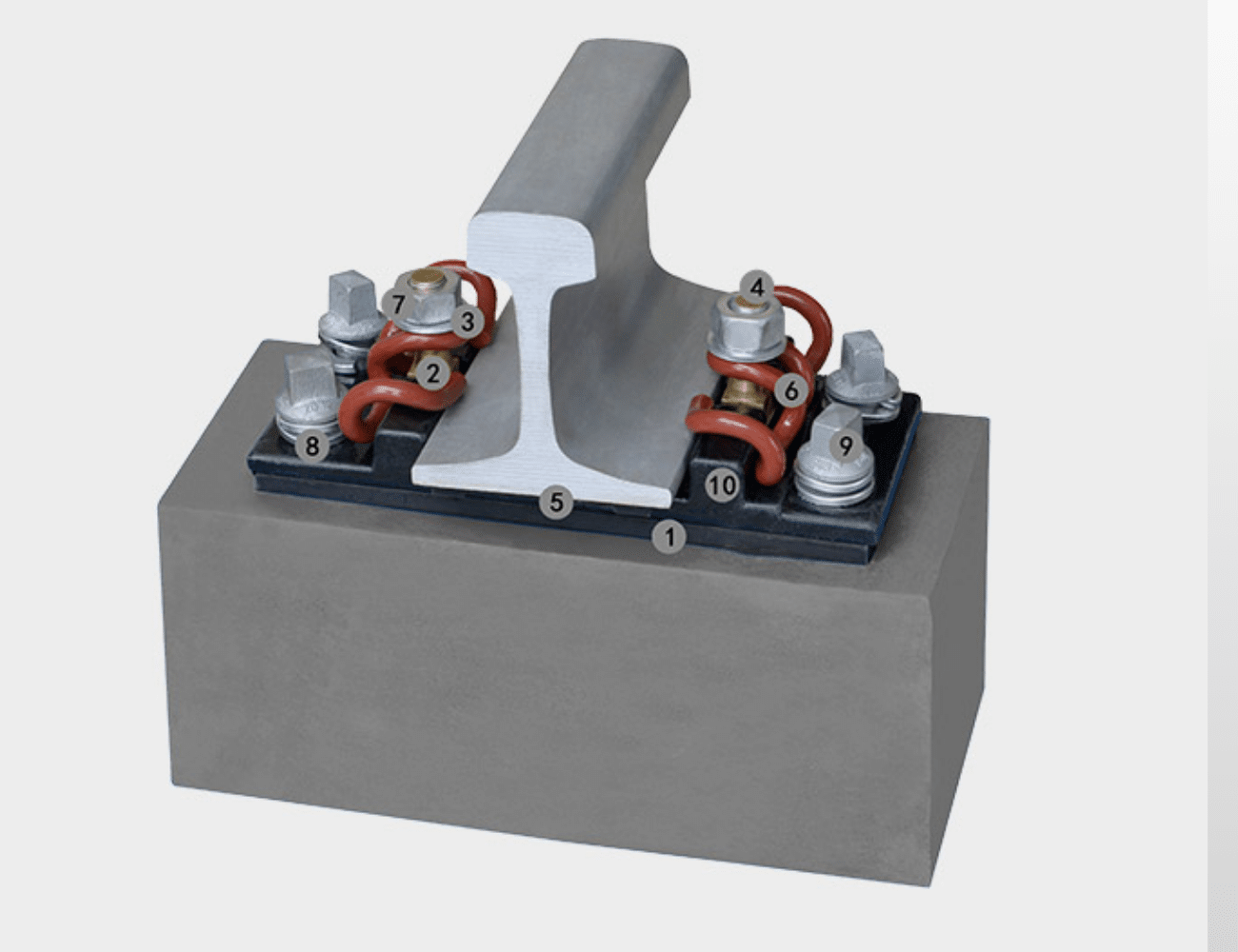

Customized fastening solutions are application-engineered connection hardware designed to overcome limitations of standard commercial fasteners in renewable energy environments. These specialized components include custom-diameter bolts, modified thread pitches, extended-length fasteners, shoulder bolts with precision tolerances, captive fasteners, quick-release mechanisms, and hybrid connection assemblies. Unlike off-the-shelf hardware, customized fastening solutions address specific technical challenges such as extreme torque requirements, vibration resistance, thermal expansion compensation, and corrosion in harsh environments. Used extensively in wind turbine blade attachments, solar panel mounting systems, battery enclosure assemblies, and hydroelectric turbine installations, these components ensure secure connections that maintain integrity throughout 20-30 year operational lifecycles. Custom fasteners optimize installation efficiency, reduce maintenance requirements, and enhance overall system reliability in renewable energy applications.

B.主な技術要件

Precision customized fastening solutions demand exacting specifications to ensure reliable performance under demanding conditions. Tolerances of ±0.002″ to ±0.005″ are standard for thread dimensions, with Class 3A/3B thread accuracy for critical applications. Head dimensions, shoulder diameters, and grip lengths require similar precision to ensure proper torque transfer and load distribution.

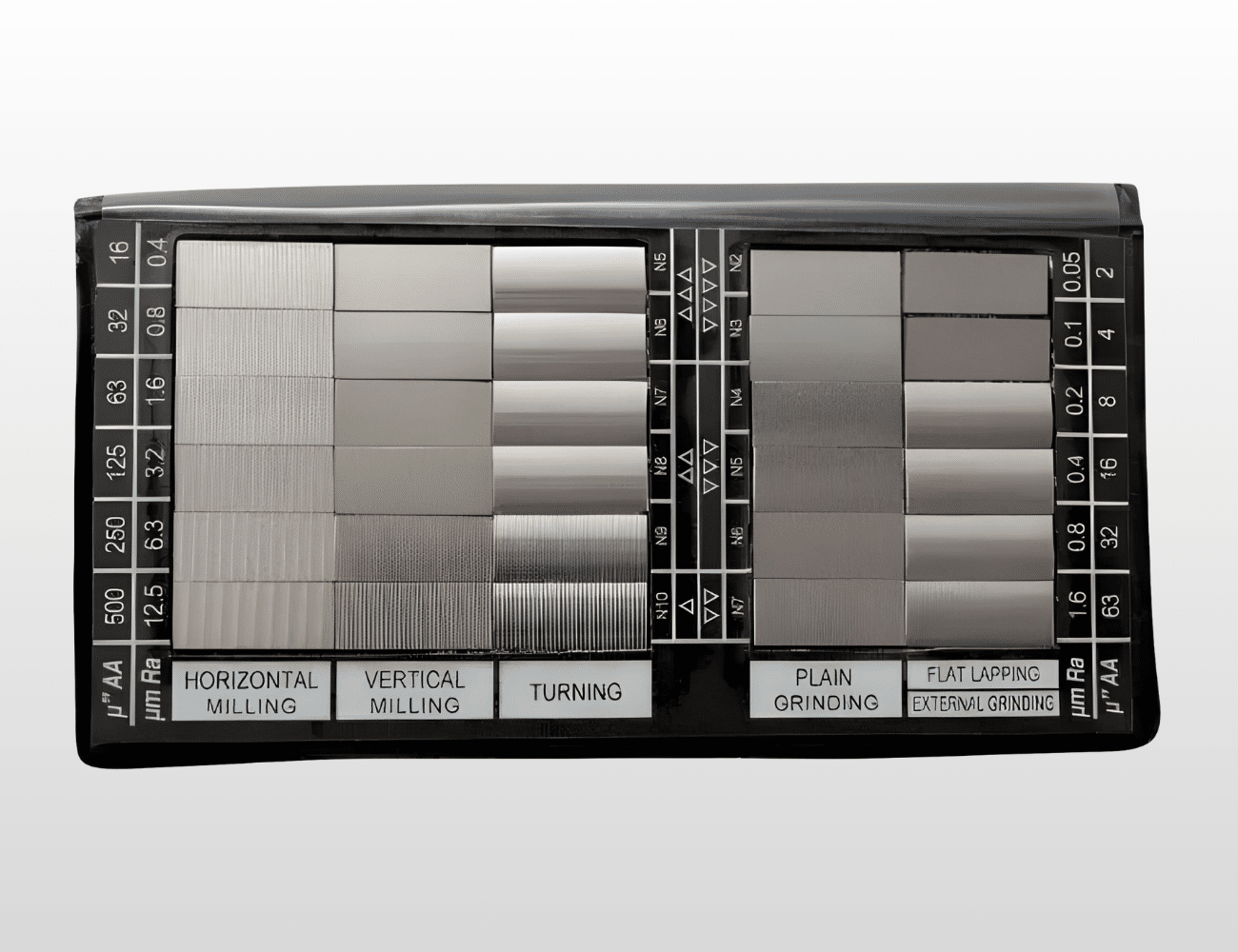

Material specifications must provide appropriate tensile strength, typically ranging from Grade 5 (120,000 psi) to Grade 8 (150,000 psi) for steel fasteners, or equivalent properties in specialty alloys. Surface finish requirements range from Ra 1.6μm to 3.2μm for threaded surfaces to minimize galling and ensure smooth assembly. Thread engagement specifications typically require minimum 1.5x diameter engagement depth for full-strength connections.

Customized fastening solutions must withstand dynamic loads, vibration cycles exceeding 10 million repetitions, and thermal cycling from -40°C to +85°C without loosening or material degradation. Corrosion resistance is critical, particularly for offshore wind and coastal solar installations. Special requirements may include non-magnetic properties, electrical conductivity or insulation, and specific coating compatibility with mating components. Material certifications verifying chemical composition and mechanical properties are mandatory for structural applications.

C.製造上の課題と解決策

Machining customized fastening solutions presents unique technical challenges due to precision requirements and material characteristics. High-accuracy threading on non-standard pitches or profiles requires specialized tooling and careful setup procedures. Hard materials like Inconel and titanium accelerate tool wear and generate significant heat during thread cutting. Maintaining concentricity between head features, shoulders, and threaded sections demands precise workholding and multi-operation sequencing. Small-diameter fasteners with extended lengths are prone to deflection and chatter during machining operations.

ワイセン・プレシジョンは、以下のような課題に取り組んでいる。 advanced multi-axis CNC Swiss-type lathes equipped with live tooling and sub-spindles for complete single-setup machining. Our thread-milling capabilities enable custom thread forms impossible with standard taps and dies. We utilize carbide and coated tooling specifically engineered for difficult materials, extending tool life and maintaining dimensional accuracy.

Quality control incorporates automated thread inspection systems using optical comparators and laser measurement for 100% verification of critical dimensions. Our thread gauge certification program ensures accuracy traceable to national standards. Hardness testing, tensile testing, and torque-tension verification confirm mechanical properties meet specifications. Climate-controlled manufacturing maintains thermal stability for precision threading operations. Contact us to learn how we solve your specific fastening challenges.

D.アプリケーションとユースケース

Customized fastening solutions manufactured by Yicen Precision serve diverse renewable energy applications:

- Wind Turbine Blade Retention – High-strength bolts for root connections and pitch bearing assemblies

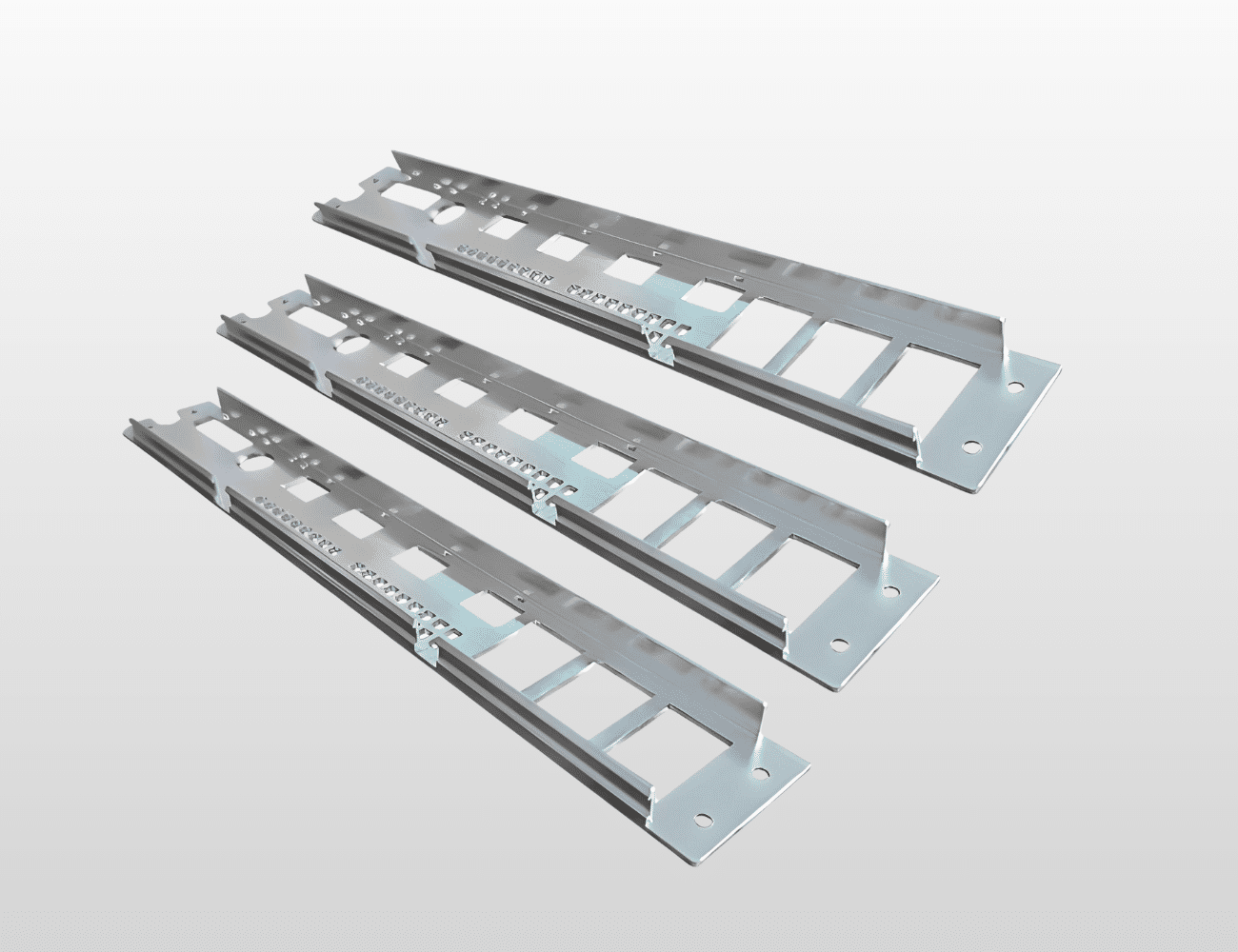

- Solar Panel Mounting Hardware – Corrosion-resistant fasteners for racking systems and tracker assemblies

- Battery Enclosure Assemblies – Specialized fasteners for energy storage system integration

- Gearbox Assembly Connections – Precision shoulder bolts and dowel pins for drivetrain components

- Electrical Connection Hardware – Custom fasteners ensuring secure conductor and busbar connections

- Maintenance Access Panels – Quick-release and captive fasteners for service accessibility

- Foundation Anchor Bolts – Extended-length custom fasteners for turbine and tracker foundations

- Vibration-Critical Assemblies – Anti-loosening fasteners with locking features and thread-locking compatibility

E. Why Choose Yicen Precision for Customized Fastening Solutions?

Yicen Precision specializes in engineering custom fastening solutions that solve real-world challenges in renewable energy installations. Our rapid prototyping capability delivers sample fasteners within 3-5 days, enabling design validation and fitment testing before committing to production tooling. We offer seamless scalability from prototype quantities to annual production volumes exceeding 100,000 units with consistent quality throughout.

私たちのエンジニアリング・チームは以下を提供します。 collaborative DFM consultation, analyzing your assembly requirements and recommending optimal fastener configurations. We evaluate thread engagement, grip lengths, material selection, and coating compatibility to enhance performance and reduce installed costs. Complete material traceability and lot tracking ensure compliance with renewable energy quality standards and facilitate field issue resolution.

By combining Swiss-style precision machining with high-volume production capabilities, we deliver cost-effective customized fastening solutions that outperform standard hardware without excessive pricing. Our strategic inventory management supports just-in-time delivery for project schedules and consignment programs for ongoing production. Request a custom quote today and discover how our customized fastening solutions CNC machining expertise solves your unique renewable energy connection challenges.