A. What are Custom Shafts and Bearings?

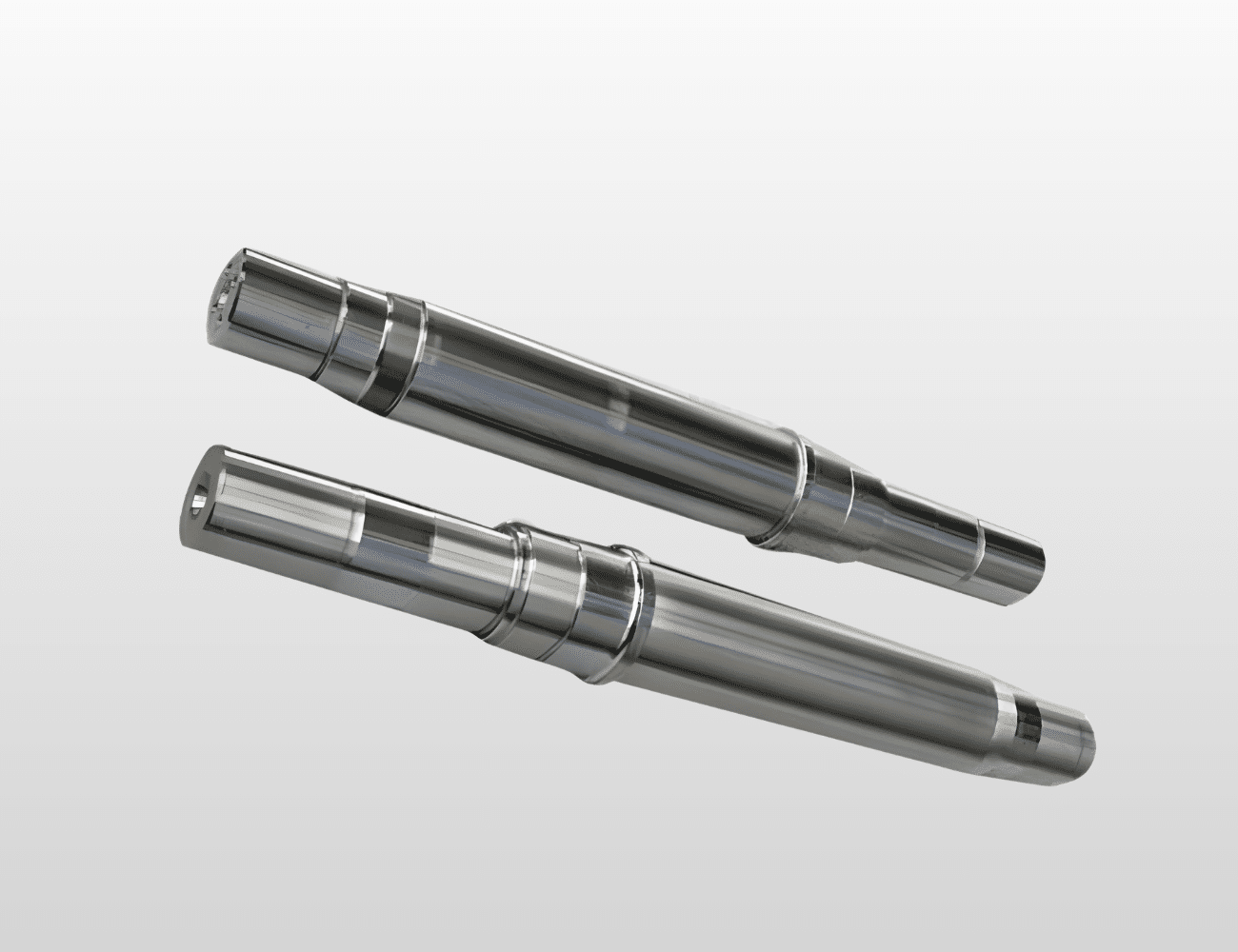

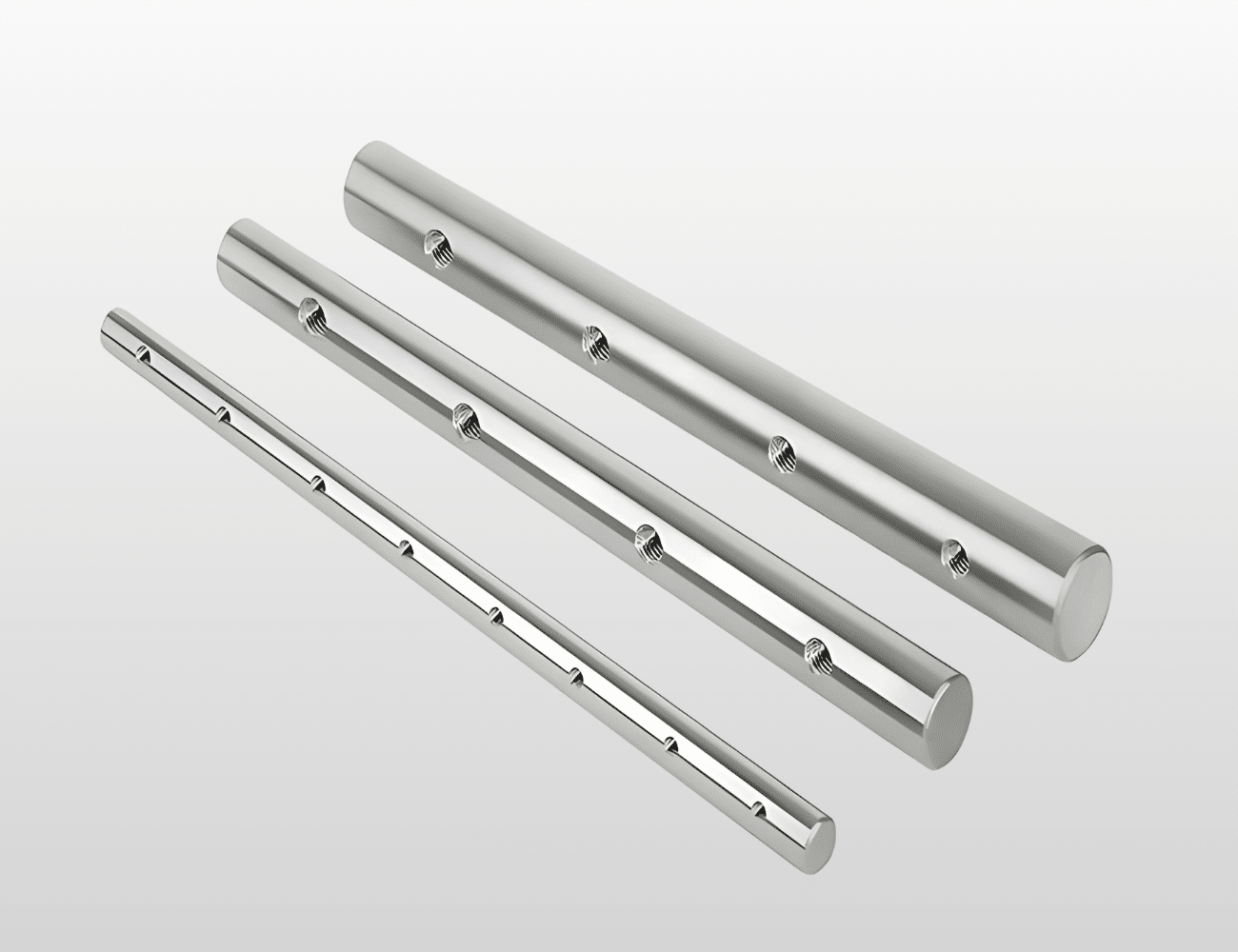

Custom shafts and bearings are precision-machined rotating and support components designed to transmit mechanical power, support radial and thrust loads, and maintain accurate positional alignment in industrial machinery. These assemblies include drive shafts, spindle shafts, intermediate shafts, bearing housings, sleeve bearings, flanged bearing blocks, and custom shaft-bearing assemblies with integrated features. They are essential in motor drives, gearbox systems, pumps, compressors, conveyor systems, and machine tool spindles. Their primary function is to enable smooth rotational motion while minimizing friction, supporting dynamic loads, and maintaining dimensional stability under continuous operation, high speeds, and varying temperature conditions.

B.主な技術要件

Precision custom shafts and bearings demand exceptionally tight tolerances with requirements of ±0.0001″ to ±0.0003″ for critical diameters, bearing seats, and shoulder dimensions. Concentricity specifications typically range from 0.0002″ to 0.0005″ TIR (Total Indicator Runout) to eliminate vibration and ensure smooth rotation. Material specifications require high-strength alloys including 4140/4340 heat-treated steel (HRC 28-32 for shafts), 52100 bearing steel (HRC 58-62 for races), 17-4 PH stainless steel, and precipitation-hardened materials for corrosive environments.

Surface finish is paramount with bearing journals requiring 8-16 Ra for optimal contact and oil retention, while general shaft surfaces range from 32-63 Ra. Straightness specifications demand less than 0.001″ per foot of length to prevent bending stress and misalignment. Roundness tolerance must be maintained within 0.00005″ on critical bearing surfaces to ensure proper load distribution and prevent edge loading conditions.

These components must endure continuous rotational speeds from 100 to 20,000 RPM depending on application, withstand radial loads exceeding 10,000 pounds, and maintain dimensional stability across temperature ranges from -40°F to 400°F. Environmental considerations include resistance to lubricants, coolants, moisture, and contaminants while preserving surface integrity and preventing corrosion or fretting damage.

C.製造上の課題と解決策

Machining custom shafts and bearings presents significant challenges including maintaining concentricity across multiple diameters with frequent setup changes, achieving ultra-smooth surface finishes on hardened materials, and preventing thermal distortion during heat treatment processes. Long, slender shafts are prone to deflection during turning operations causing taper and diameter variations. Interrupted cuts on keyways and cross-holes can induce vibration affecting surface finish. Bearing seat dimensions require absolute precision as even 0.0001″ deviation affects press-fit interference and load capacity.

Yicen Precision overcomes these challenges through dedicated precision turning centers with live tooling and sub-spindle capabilities enabling complete shaft machining in single setups, eliminating concentricity errors from multiple fixturing. We employ rigid steady rests and tailstock support for long shaft turning to prevent deflection. For hardened components, our hard turning capabilities with CBN (Cubic Boron Nitride) tooling achieve bearing-quality surface finishes without grinding.

Our precision cylindrical grinding equipment delivers 4-8 Ra surface finishes with diameter control within ±0.00005″ and roundness tolerances to 0.00002″. Post-heat treatment distortion is managed through stress-relieving protocols and precision straightening operations verified with dial indicators. All custom shafts and bearings undergo comprehensive inspection including CMM verification, surface profilometry, concentricity measurement, and dynamic balancing for high-speed applications. Material certifications and full dimensional reports accompany every shipment.

D.アプリケーションとユースケース

Industrial machinery custom shafts and bearings manufactured by Yicen Precision serve diverse critical applications:

- Electric Motor Assemblies – Armature shafts, rotor shafts, and bearing housings for industrial motors

- ポンプとコンプレッサーシステム – Drive shafts, impeller shafts, and journal bearing assemblies

- Machine Tool Spindles – High-speed precision spindle shafts with integrated bearing seats

- Conveyor Systems – Roller shafts, idler shafts, and pillow block bearing housings

- Gearbox Assemblies – Input/output shafts, intermediate shafts, and bearing carriers

- Industrial Mixers – Agitator shafts and heavy-duty bearing supports for high-torque applications

- Printing and Paper Machinery – Precision roller shafts with tight concentricity requirements

- 物流機器 – Crane drum shafts, hoist shafts, and load-bearing pivot assemblies

E. Why Choose Yicen Precision for Custom Shafts and Bearings?

Yicen Precision offers unparalleled expertise in manufacturing custom shafts and bearings with guaranteed concentricity, surface finish excellence, and dimensional accuracy that meets the most demanding specifications. Our integrated capabilities spanning turning, milling, grinding, and heat treatment enable complete shaft-bearing assembly manufacturing under one roof, ensuring quality control and faster delivery times. We provide value-added engineering support including bearing fit analysis, stress calculations, and DFM recommendations to optimize performance and manufacturability.

Our advanced metrology laboratory features CMM equipment, surface finish analyzers, and precision measuring instruments calibrated to NIST standards ensuring absolute accuracy verification. We maintain partnerships with premium steel mills and specialty material suppliers guaranteeing certified material quality and competitive pricing. Our production scalability accommodates orders from single prototype shafts to production runs exceeding 50,000 units annually with consistent precision across every component. With dedicated shaft manufacturing expertise and specialized equipment investments, we deliver custom shafts and bearings that exceed industry standards for reliability and performance.

Contact our engineering team for a detailed quote on your custom shafts and bearings CNC machining project.