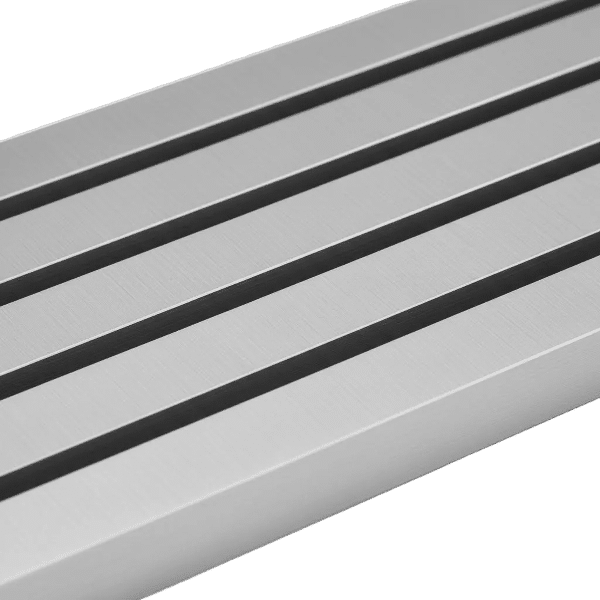

The surface finish options for Wire EDM depend on the part requirements. For smooth finishes, we offer skim cuts and multi-skim finishes, while As-Cut finishes are perfect for parts that do not require post-machining.

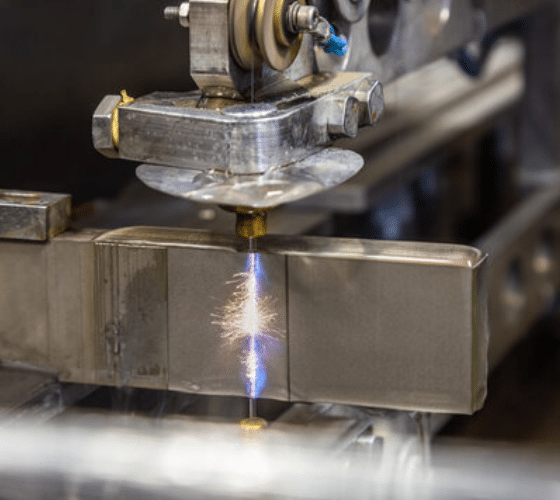

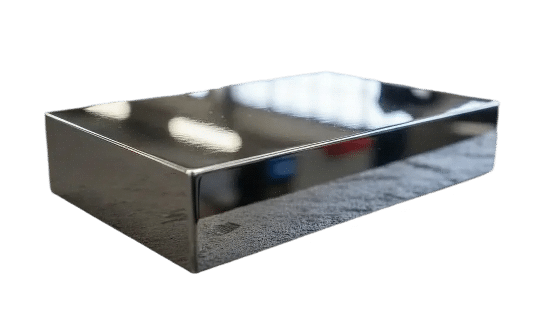

で イーセン精密, we specialize in Wire EDM machining that delivers high-precision, tight-tolerance cuts for a wide range of metals and plastics. Our advanced technology ensures that your components are made with unmatched accuracy, achieving tolerances down to ±0.001″ (±0.025 mm). Whether you’re working on prototypes or high-volume production runs, we offer fast turnaround times and consistently high-quality results.

ISO 9001:2015|AS9100D|ISO13485|ITAR準拠

第11,086,292号、第11,347,201号、第11,693,388号、第11,698,623号、第12,099,341号、第12,189,361号。その他特許出願中。

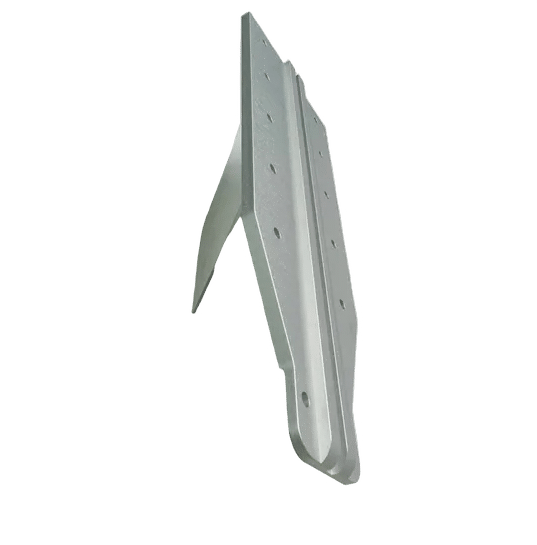

Wire EDM is a high-precision and complex geometries. Industries that need quality, complex components and parts are vital to it.

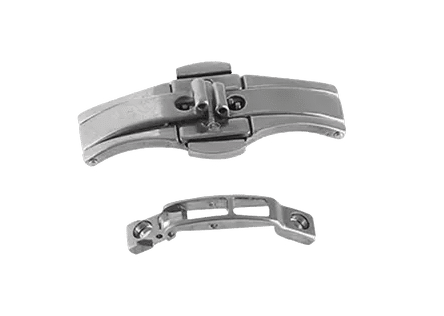

Wire EDM is also used to cut complex parts to very tight tolerances, so it is ideal in aerospace and in other high-precision applications.

Wire EDM helps to accelerate projects and scale effort while still maintaining high accuracy and supporting high-volume production and fast-prototyping.

Wire EDM has a great variety of materials that it can machine such as hard metals and alloys, and it is applicable in various sectors.

Wire EDM machining offers exceptional precision, making it the perfect choice for intricate parts with tight tolerances. Whether you need standard, high-precisionあるいは micro tolerances, イーセン精密 can meet the most stringent demands across various industries.

|

オペレーション |

Max Tolerance |

Max Build Size |

Typical Dimensional Tolerance |

|

General-Purpose Wire EDM |

±0.005 mm |

300 mm x 300 mm x 300 mm |

±0.005 mm |

|

Precision Wire EDM |

±0.002 mm |

500 mm x 500 mm x 500 mm |

±0.002 mm to ±0.003 mm |

|

High-Performance Wire EDM |

±0.001 mm |

600 mm x 600 mm x 600 mm |

±0.001 mm to ±0.002 mm |

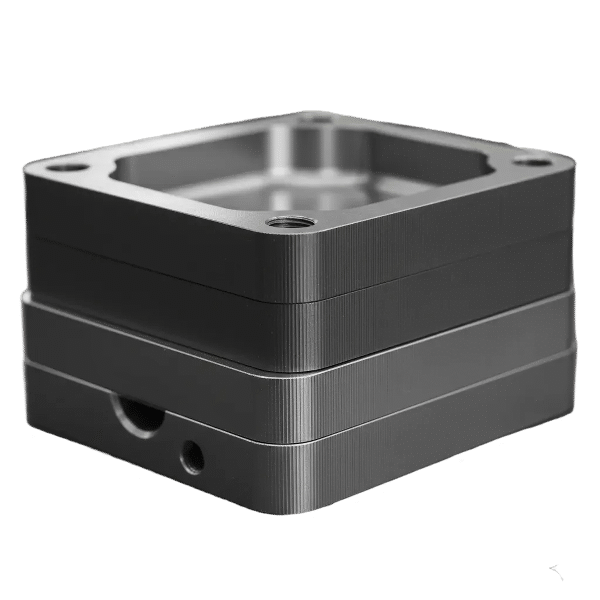

EMD machines come in 2, 4, and 5 axis formations. All models are customized to the requirements of particular types of cuts such as a basic 2D cut and complicated 3D shapes, which provide accuracy, versatility, and effectiveness.

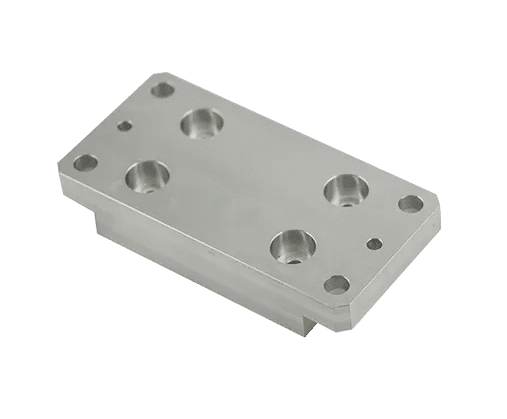

General-purpose Wire EDM Ideal in general machining, high precision of General-purpose wire EDM is at tolerances of = -0.005 mm in most applications.

Precision Wire EDM is known to be fine and tolerances of ± 0.002 mm making it appropriate in the complex parts that require tight control.

High tolerance of equal or less than ±0.001mm, High-performance wire EDM is constructed with critical aerospace and medical applications and is engineered to provide maximum precision and reliability.

Micro Wire EDM is a specialist in small, fine components and achieves tolerances on the order of 0.0005mm, ideal in microelectronics and semiconductor components.

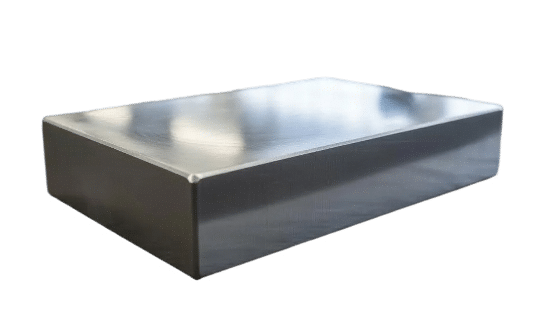

Workpieces served by this service are up to 1000 mm. It provides very fine cuts with a tolerance of up to 0.01 mm, applicable in large industrial and heavy parts.

The Advanced Multi-Axis-Wire EDM delivers multi-dimensional cuts with better accuracy and versatility that are suited to parts with complicated geometries requiring high detail.

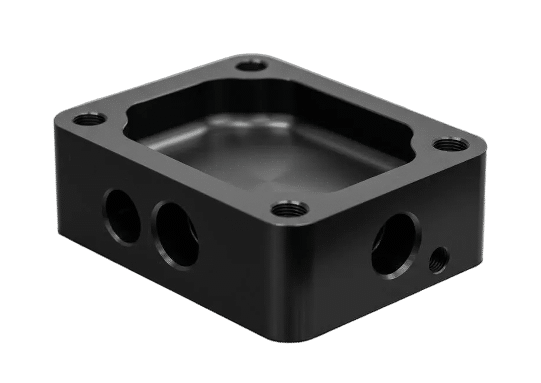

We specialize in cutting a wide range of materials with precision and high-quality results. Here’s a list of materials we commonly work with

| Specific Material Type | 説明 | 仕上げオプション | 主な用途 |

| High-Speed Steel (HSS) | Maintains hardness even at high temperatures | Polishing & Coating | Industrial Cutting Tools |

| Cold-Work Tool Steel | Designed for low-temperature applications | Fine Sanding | Stamping & Blanking Dies |

| Hot-Work Tool Steel | Resists thermal cracking under heat | Protective Coating | Die Casting Molds |

| Shock-Resisting Steel | Handles sudden impacts without breaking | Surface Buffing | Pneumatic Chipping Tools |

| Air-Hardening Steel | Minimizes distortion during heat treatment | 精密研削 | Complex Injection Molds |

| Specific Material Type | 説明 | 仕上げオプション | 主な用途 |

| Case-Hardened Steel | Hard outer shell with a tough core | High-gloss Polishing | Gears & Camshafts |

| Through-Hardened Steel | Consistent hardness throughout the part | Industrial Sanding | High-stress Fasteners |

| Nitridable Steel | Surface hardened using nitrogen gas | Specialized Coating | Precision Engine Parts |

| Induction-Hardened Steel | Locally hardened via magnetic fields | Surface Lapping | Shafts & Axles |

| Pre-Hardened Steel | Delivered already at the required hardness | 硬質クロムメッキ | Large Machinery Frames |

| Specific Material Type | 説明 | 仕上げオプション | 主な用途 |

| Solid Carbide | Pure compound used for maximum rigidity | Diamond Polishing | High-precision End Mills |

| 炭化タングステン | Most common for extreme wear resistance | ビーズブラスト | Mining & Rock Drilling |

| Cobalt-Bonded Carbide | Tougher variant for impact resistance | Precision Deburring | Metal Stamping Inserts |

| 炭化ケイ素 | Ceramic-like properties for high heat | High-clarity Finish | High-temperature Seals |

| Titanium Carbide | Lightweight variant for high-speed use | Fine Grit Blasting | Aerospace Cutting Tips |

| Specific Material Type | 説明 | 仕上げオプション | 主な用途 |

| 6061 Aluminum | Most versatile grade for structural use | Color Anodizing | Automotive Frames |

| 7075 Aluminum | High-strength alloy as strong as steel | Professional Polishing | Aerospace Components |

| 5052 Aluminum | Excellent for marine environments | クリアコーティング | Marine Hardware |

| 2024 Aluminum | Superior fatigue resistance | Linear Brushing | Aircraft Structures |

| Cast Aluminum | Ideal for complex shapes and molds | パウダーコーティング | Engine Manifolds |

| Specific Material Type | 説明 | 仕上げオプション | 主な用途 |

| グレード 5 (Ti-6Al-4V) | The standard high-strength aerospace alloy | Smooth Polishing | タービンブレード |

| グレード2(市販純度) | Highly resistant to chemical corrosion | Fine Blasting | Chemical Processing |

| Grade 23 (ELI) | High-purity grade for medical use | Micro Deburring | Surgical Implants |

| Beta Titanium | More flexible for springs and frames | Acid Etching | Eyeglass Frames |

| Titanium-Aluminide | For extreme high-temperature zones | Hard Anodizing | Turbochargers |

| Specific Material Type | 説明 | 仕上げオプション | 主な用途 |

| インコネル718 | High strength and oxidation resistance | High-temp Polishing | Rocket Engines |

| インコネル625 | Excellent for underwater applications | Heavy Blasting | Subsea Equipment |

| ハステロイ | Superb resistance to harsh acids | Precise Deburring | Chemical Reactors |

| モネル | Nickel-copper alloy for salt water | Thermal Coating | Marine Shafting |

| Waspaloy | Maintains strength at over 1200°F | Special Machining | Gas Turbine Disks |

| Specific Material Type | 説明 | 仕上げオプション | 主な用途 |

| Pure Copper (C101/C110) | Peak electrical conductivity | Fine Polishing | Electrical Connectors |

| フリーカッティング・ブラス | Easy to machine and decorative | Soft Blasting | Plumbing Fittings |

| Beryllium Copper | High strength with conductivity | Smooth Deburring | Precision Springs |

| Phosphor Bronze | Resistant to fatigue and wear | Bright Buffing | Marine Bearings |

| Nickel Silver | Corrosion resistant with silver look | Clear Plating | Musical Instruments |

| プラスチック素材 | 説明 | 仕上げオプション | アプリケーション |

|---|---|---|---|

| Carbon-Filled PEEK | A high-performance, conductive plastic used in aerospace and medical parts | Polishing, Blasting, Deburring | Aerospace, Medical Devices, High-Performance Parts |

| Metal-Filled ABS | ABS plastic mixed with metal powders for conductivity | Polishing, Blasting, Sanding | Electronics, Static Dissipative Parts |

| Conductive PTFE | PTFE (Teflon) filled with carbon for low friction and conductivity | Polishing, Sanding, Blasting | Industrial Applications, Electrical Insulation |

| Conductive Nylon | ナイロン で満たされている。 carbon to achieve conductivity | Polishing, Blasting, Sanding | Automotive, Electronics, Industrial Tools |

| Carbon-Filled Polycarbonate | Polycarbonate combined with carbon for conductivity | Polishing, Blasting, Coating | Electronics Enclosures, Mechanical Components |

| PP | ポリフェニレン、高い機械的および熱的特性。 | 機械加工、サンディング、研磨 | 自動車、電気部品、産業用途 |

| PA66 | ポリアミド(ナイロン66)、高い機械的強度と剛性。 | 機械加工、サンディング、研磨 | 機械部品、自動車、電気絶縁 |

| PEI | ポリエーテルイミド(ウルテム)、高い強度と優れた電気特性。 | 機械加工、サンディング、研磨 | 航空宇宙、医療機器、電気部品 |

| サン | スチレン-アクリロニトリル、良好な耐薬品性と透明性。 | 機械加工、サンディング、研磨 | 家庭用品、化粧品容器、自動車部品 |

| ヒップ | 高衝撃性ポリスチレン、優れた耐衝撃性と機械加工性。 | 機械加工、サンディング、塗装 | 包装、消費者製品、電気絶縁 |

| じんこうこていしさん | ハイインパクトポリプロピレン、高い耐衝撃性と低密度。 | 機械加工、サンディング、塗装 | 自動車部品、産業用途、消費財 |

| 繊維強化素材 | 機械的特性を向上させた複合材料。 | 機械加工、サンディング、塗装 | 航空宇宙、自動車、スポーツ用品 |

To ensure the best results and cost-effective production using ワイヤー放電加工機, following these design guidelines will help minimize machining time, improve accuracy, and maintain part geometry stability.

| ファクター | Professional Guideline |

| 素材タイプ | Use conductive metals like tool steel and titanium. |

| 寛容 | Ensure machine precision meets ±0.001 mm requirements. |

| Workpiece Size | Ensure size fits machine’s capacity (e.g., 300mm x 300mm). |

| Wire Type | Use brass/copper wire; use diamond wire for finer cuts. |

| Coolant Use | Use deionized water or dielectric fluids for cooling. |

| 表面の完全性 | Optimize pulse settings to prevent surface micro-cracking. |

| Flush Pressure | Maintain high pressure to clear debris from deep cuts. |

| Wire Tension | Control tension strictly to maintain vertical accuracy. |

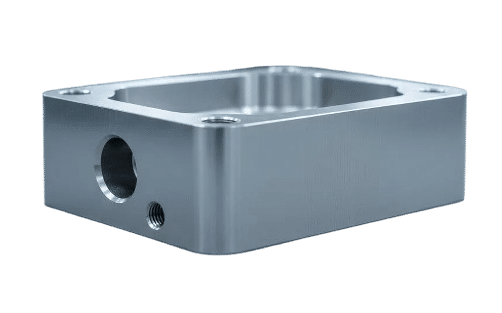

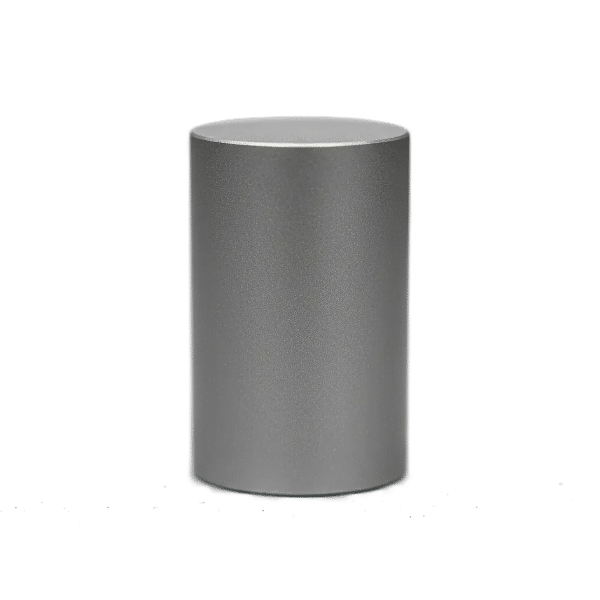

Precision-turned parts benefit from specialized surface treatments that enhance strength, durability, and overall performance. These finishes are ideal for optimizing the functionality of shafts, bushings, and cylindrical components.

A rough cut finish is left by Wire EDM, often used for fast cuts in initial prototyping or non-critical components

The bare finish, leaving the tool marks and sharp edges, has a roughness of approximately 125 µin Ra on its surface.

Offers smooth and burr-free surfaces through the removal of sharp edges, which enhances safety and general quality.

After cutting with ワイヤー放電加工機, the burnished finish provides a slightly shiny, smooth surface, ideal for high-durability applications.

Provides a non-reflective surface, ideal with long lasting components that do not require a lot of reflection.

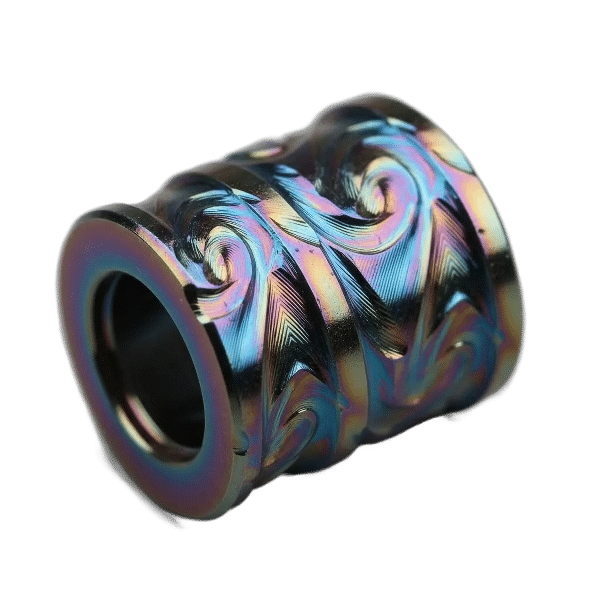

Creates practical or ornamental textures, which include complex patterns and surface qualities.

Achieve a smooth, glossy, polished finish, reducing roughness for parts requiring enhanced shine and aesthetic appeal.

Produces a smooth and reflective surface, which is best suited for aesthetic components and the narrowing of tolerances.

We adhere to ISO 9001:2015, AS9100Dそして ISO 13485 standards, ensuring that every part we produce meets the highest quality benchmarks. Our inspection process is rigorous, covering every stage from prototype development への full production, guaranteeing that each part meets your 寛容 そして 表面仕上げ スペック

We use CMM (Coordinate Measuring Machines), digital micrometers, and optical measurement systems to check all critical features with micron-level precision.

We ensure that parts meet ISO 2768-mK and ASME Y14.5 standards, verifying accurate form, position, and profile throughout the production process.

We inspect surface roughness (Ra 3.2-0.8 mm) and coating thickness to ensure the performance and appearance of each part meet your requirements.

Wire EDM Services for Precision Components Experience precision that matters. Our expert CNC machining and Wire EDM services combine extreme accuracy with high-performance engineering to tackle even the toughest materials. Whether you need intricate prototypes or large-scale production, our advanced Wire EDM technology ensures every cut is sharp, consistent, and built to your exact specs.

当社の安全なオンラインプラットフォームからCADファイルを簡単にアップロードして、作業を開始できます。

お客様のプロジェクトのニーズに合わせて、材料、仕上げ、公差、ご希望のリードタイムをお選びください。

お客様のデザインと選択された仕様に基づき、リアルタイムでお見積もりをお出しします。

お客様の部品は、信頼できるパートナーによって製造され、品質検査が行われた後、納期通りにお客様のお手元に届けられます。

で イーセン精密, we pride ourselves on providing high-quality Wire EDM machining backed by years of experience and a proven track record in delivering precise, complexそして カスタムパーツ for a wide range of industries.

We deliver parts with tight tolerances (±0.001″ or better), ensuring top-quality precision for your projects.

With experience in 航空宇宙, メディカルそして 自動車, we’ve built a reputation for high-precision machining in demanding industries.

Quick prototyping そして rapid production to meet your tight deadlines, without compromising quality.

Specializing in intricate designs そして 複雑な幾何学, we turn the most challenging projects into reality.

私たちの engineering team 専門家 guidance on material selection, tolerancesそして design for manufacturability to optimize production.

We offer tailored Wire EDM services to meet your specific project requirements, delivering the best possible results every time.

Advantages

Wire EDM provides several benefits that make it ideal for manufacturing complex parts そして high-precision components.

アプリケーション

Wire EDM is widely used across industries for high-precision parts, offering the ability to cut complex shapes そして tight tolerances with ease.

私たちは、お客様のアイデアを比類のないスピードと精度で、高品質で機能的な部品に変換することを専門としています。高度な技術と熟練した職人技で、最も複雑な仕様を満たす部品を作り出します。

How Do I Choose the Right Surface Finish for My Wire EDM Project?

The surface finish options for Wire EDM depend on the part requirements. For smooth finishes, we offer skim cuts and multi-skim finishes, while As-Cut finishes are perfect for parts that do not require post-machining.

What Tolerances Can Wire EDM Achieve?

Wire EDM can achieve tolerances as tight as ±0.001″ (±0.025 mm), making it ideal for high-precision parts in industries such as aerospace, automotive, and medical devices.

How Accurate Is Wire EDM Machining?

Wire EDM is known for its unmatched accuracy, delivering parts with tight tolerances and the ability to cut intricate geometries. It offers high-precision machining for even the most complex parts.

Can Wire EDM Machine Hardened Steel?

Yes, Wire EDM is highly effective in machining hardened steels and other tough materials. It is especially useful for cutting high-hardness materials that other machining methods may struggle with.

How Does Wire EDM Compare to Laser Cutting?

Unlike laser cutting, which uses heat, Wire EDM offers contact-free machining with no heat-affected zones, making it ideal for precise cuts in small or delicate parts and materials that may distort under heat.