Custom CNC Turning Services

High-precision CNC turning solutions for prototypes and production parts that demand consistent accuracy, smooth surface finishes, and stable dimensional performance. Our multi-axis turning centers deliver reliable results across metals and engineering plastics, supported by ISO-certified quality processes and fast global turnaround.

- すべてのアップロードは安全かつ機密です。

新しいCNC見積もりを始める

ISO 9001:2015|AS9100D|ISO13485|ITAR準拠

第11,086,292号、第11,347,201号、第11,693,388号、第11,698,623号、第12,099,341号、第12,189,361号。その他特許出願中。

What Is CNC Turning?

CNC turning is a precision machining process used to create accurate cylindrical and concentric components by removing material from rotating stock. The controlled toolpaths deliver stable diameters, clean surface finishes, and consistent dimensional repeatability for both prototypes and production parts.

How CNC Lathes Operate

A spindle rotates the raw material while cutting tools shape external and internal features such as profiles, bores, grooves, and threads. This method ensures stable geometry and predictable accuracy.

Turning Configurations

Different types of lathes handle different levels of work, from basic turning of round parts to advanced machines that produce very small or complex shapes. Each type helps improve stability, tool control, and accuracy during machining.

Turning Workflow

The machine executes programmed feeds, speeds, and tool motions to achieve precise dimensions.

Maximum CNC Turning Capabilities

Our CNC turning capabilities are engineered for consistent accuracy, smooth finishes, and efficient production cycles across metal and plastic components. Each setup supports reliable machining for both prototypes and large-batch manufacturing.

CNCフライス加工は、3軸、4軸、5軸加工機を使用して、金属やプラスチック材料を精密で再現性のある形状に切削するサブトラクティブ加工技術です。複雑な形状、厳しい公差、試作品や生産部品の高い表面仕上げに最適です。

We provide precision CNC machining services for custom parts in metals and engineering plastics. From prototypes to production runs, every component is machined to tight tolerances with consistent, repeatable accuracy.

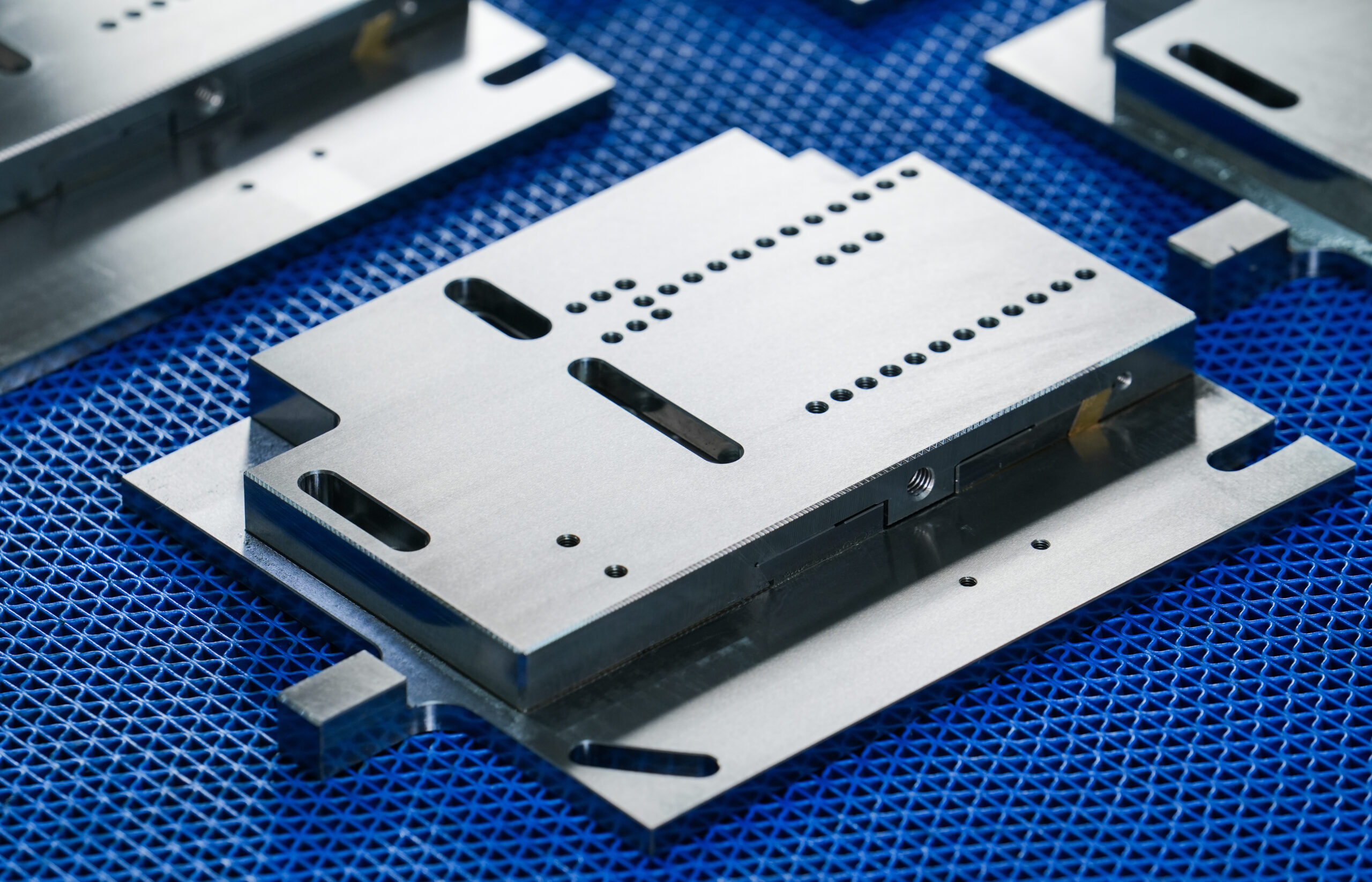

機械加工、組立、検査工程を改善する精密治具と固定具を設計、製造しています。当社の治具は高精度のCNC加工により製造され、少量生産から大量生産まで、安定性、再現性、耐久性に優れています。

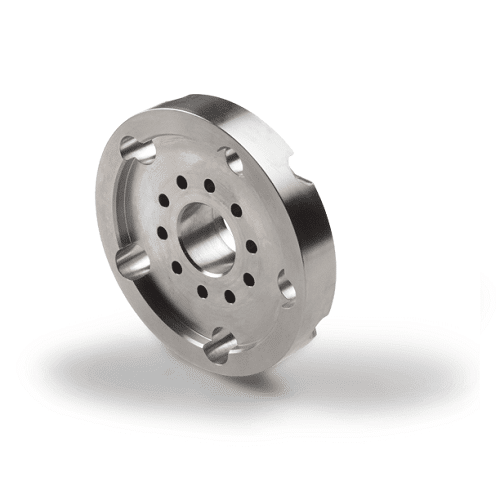

CNC Turned Parts for Precision Components

エキスパート precision cnc turning services, where accuracy meets performance at every stage. From intricate prototypes to production-ready components, our custom cnc turning services deliver high-accuracy parts. Every cut, every contour, crafted with exceptional quality, consistency, and attention to detail.

CNC旋盤用素材

Yicen Precisionは、迅速な試作と耐久性のある高性能部品を提供し、エンジニアや大手メーカーから信頼を得ています。プロトタイピングであれ、本格的な生産であれ、当社の豊富な材料セレクションは、あらゆるCNC機械加工プロジェクトの精度、強度、信頼性を保証します。

アルミニウム

アルミニウム 5052

アルミニウム 7075 & 7075-T6

アルミニウム 6063-T5

アルミニウム 7050-T7451

アルミニウム MIC-6

アルミニウム 6061-T6

アルミニウム 2024-T3

ブロンズ/真鍮

真鍮 C360

ブラス260

C932 M07 ベアリング・ブロンズ

銅

H59

H60

プラスチック

ABS

アセタール[デルリン]

アクリル、G-10ガロライト

ナイロン6/6

覗き見

ポリカーボネート

PTFE【テフロン

ポリプロピレン

超高分子量ポリエチレン

スチール

合金鋼 4130

合金鋼 4140

ASTM A36

ステンレス 15-5

ステンレス・スチール 17-4

ステンレス・スチール18-8

ステンレス・スチール303

ステンレス鋼304

ステンレス鋼 316/316L

ステンレス鋼 416

ステンレス鋼420

スチール 1018

スチールA36

チタン

チタン・グレード2

チタン 6Al-4V

亜鉛

亜鉛シート合金 500

CNC旋盤公差

Our turning centers support a wide range of diameters, lengths, and feature types, ensuring reliable machining for small precision components and larger rotational parts.

| オペレーション | Max Diameter | Max Length |

|---|---|---|

| Standard Turning | Ø300 mm | 500 mm |

| Live Tooling | Ø250 mm | 400 mm |

| Swiss-Type Turning | Ø32 mm | 150 mm |

CNC旋盤の表面仕上げ

精密旋盤加工部品は、強度、耐久性、全体的な性能を向上させる特殊な表面処理の恩恵を受けます。これらの処理は、シャフト、ブッシュ、円筒形部品の機能を最適化するのに理想的です。

最も迅速で経済的なオプションで、目に見えるツールマークが残り、鋭利なエッジやバリが発生する可能性がある。表面粗さは約125 µin Raで、ご要望に応じてバリを除去することも可能です。

硬度、耐摩耗性、耐久性を高める厚いクロムコーティング。シャフトやピストンなどの高負荷部品に最適。

耐摩耗性と耐食性を高める薄い電気めっきニッケル層。機能部品に明るく魅力的な仕上げを提供します。

スチール部品の表面を黒くつや消しの黒色にする化学処理。穏やかな耐食性を提供し、光の反射を抑える。

機械的バフ研磨により、滑らかで光沢のある仕上がりが得られます。光沢が必要な装飾部品に最適。

研磨ベルトやブラシを使った、直線的でサテンのようなテクスチャー。細かな凹凸を減らし、きれいで装飾的な外観に仕上げる。

特定の仕上げが必要ですか?RFQをご提出いただければ、お客様のプロジェクトに合わせたソリューションをご提案いたします。

通常ガラスビーズを使用するメディアブラストにより、滑らかでマットな仕上がりを実現。

Key Features of CNC Turning

Our CNC turning capabilities are engineered for consistent accuracy, smooth finishes, and efficient production cycles across metal and plastic components. Each setup supports reliable machining for both prototypes and large-batch manufacturing.

| Heading | 説明 |

|---|---|

| High Dimensional Accuracy | Stable spindle control and rigid toolpaths maintain tight diameter, roundness, and concentricity requirements. |

| Smooth Surface Finishes | Rotational cutting produces clean surfaces ideal for sealing fits, sliding interfaces, and precision assemblies. |

| Efficient for Cylindrical Geometries | Cost-effective machining for shafts, bushings, pins, connectors, and other rotational components. |

| Fast Setup & Short Lead Times | Turning centers allow quick tool changes and reduced cycle time, supporting rapid prototyping and scaling. |

| Live Tooling Support | Add milled flats, threads, grooves, slots, or cross-holes in a single setup for better accuracy and lower cost. |

| Stable Repeatability for Production | Rigid fixturing and automated toolpath control deliver consistent part geometry across long production runs. |

CNC Turning Design Guidelines

Effective design choices help reduce machining time, improve accuracy, and maintain stable part geometry during turning.

| パラメータ | 仕様 | なぜ重要なのか |

| Internal Radii | Avoid sharp corners; recommended radius: 2.6 × tool diameter. | Prevents tool vibration and ensures stability in deep pockets. |

| Threads & Tapped Holes | Depth = 3× Ø (small) or 4× Ø (larger threads). | Prevents tool breakage and ensures strong thread engagement. |

| 最小肉厚 | Metals: 0.3–1.0 mm / Plastics: 1.2–1.5 mm. | Prevents vibration, deflection, and machining marks. |

| Hole Sizes & Depth | Min diameter: 0.50 mm / Max depth: 4× diameter. | Ensures reliable chip evacuation and precision bore accuracy. |

| アンダーカット | Supports square, full radius, and dovetail profiles. | Using standard profiles reduces machining time and cost. |

| Text & Engraving | Min width: 0.6 mm / Min depth: 0.1 mm. | For turned parts, laser engraving is preferred for finer marking. |

| Avoid Over-Constraint | Design for stable surfaces and supported geometries. | Reduces the need for excessive fixturing and complexity. |

| DFM Review | Engineering check for manufacturability and tool access. | Ensures high-quality output and efficient production cycles. |

Quality Assurance & Inspection Capabilities

Every turned part is inspected using certified metrology workflows to ensure dimensional accuracy, surface integrity, and repeatable performance across all production volumes.

寸法精度

CMM inspection for critical datums, diameters, roundness, and concentricity

Bore gauges, micrometers, and height systems for fast in-process checks

Supports tight-tolerance features down to ±0.001 in (±0.025 mm)

GD&T & Tolerance Verification

Surface roughness checks (Ra 3.2 μm standard; Ra 0.8 μm optional)

Runout and concentricity measurement for rotational components

Compliance with turning-specific finishing standards

Surface & Finish Testing

Inspection aligned with ISO 2768-mK and ASME Y14.5

Verification of profile, position, perpendicularity, parallelism, circularity

Ensures geometric stability under real machining conditions

Traceability & Reporting

FAI reports, material certificates (MTRs), and CMM data available

Lot tracking for aerospace, medical, and industrial requirements

Secure record-keeping for full audit trail and quality compliance

Applications of CNC Turning

CNC turning is ideal for precision rotational components where concentricity, smooth surface finishes, and consistent dimensional control are critical.

Shafts & Axles

For motors, gear assemblies, automation systems, and drive mechanisms where straightness, runout, and load-bearing interfaces matter.

Bushings & Spacers

High-accuracy cylindrical components for reducing friction, maintaining alignment, and supporting rotational motion.

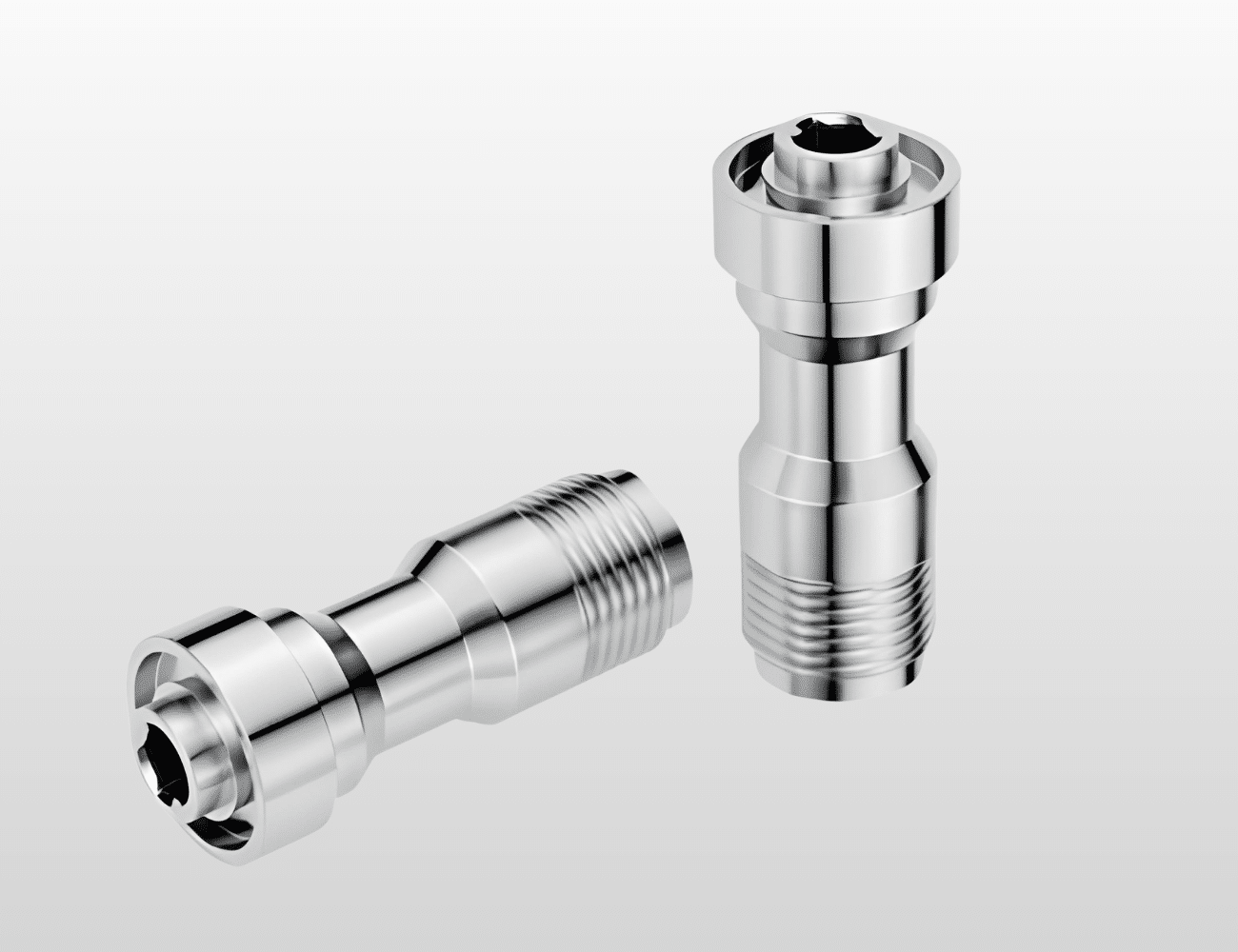

Threaded Connectors & Fittings

Precision internal/external threads for hydraulic, pneumatic, and mechanical systems; supports ISO/ASME thread standards.

Pins, Dowels & Couplers

Used for alignment, load transfer, and joining mechanisms in automotive, aerospace, and machinery assemblies.

Sleeves, Housings & Collars

Turned enclosures and structural rings requiring tight diametrical tolerances and smooth surface profiles.

Hydraulic & Pneumatic Components

Valves, adapters, and pressure-line components requiring concentric sealing surfaces and controlled tolerances.

Custom Rotational Components

Specialized geometries, stepped profiles, and multi-diameter parts for prototypes, tooling, and production assemblies.

Why Choose Yicen Precision to CNC Turning ?

We deliver reliable, production-ready turned parts with consistent accuracy, fast lead times, and engineering support built around real manufacturing requirements.

Micron-Level Precision

Stable, repeatable accuracy down to ±0.001″ for rotational components requiring controlled runout and concentricity.

Advanced Multi-Axis Turning Centers

Live tooling, Swiss-type, and multi-axis equipment allow complex features, reduced setups, and better dimensional consistency.

Support for Manufacturability

Our team reviews geometry, material selection, tolerances, and thread standards to ensure optimal machining and lower cost.

ISO-Certified Quality Systems

ISO-Certified Quality Every part passes through controlled inspection workflows aligned with ISO 9001:2015, AS9100D, and ISO 13485 standards.

Reliable Global Delivery

Secure logistics, protective packaging, and validated workflows ensure parts arrive on time and within specification.

Fast Prototyping & Scalable Production

From rapid prototypes to high-volume production runs, we maintain stable lead times with predictable output.

易泉機械加工ソリューション

小ロットのカスタムパーツを製作する場合でも、大量生産のために規模を拡大する場合でも、Yicenの機械加工サービスは必要な柔軟性を提供します。

CNCラピッドプロトタイプ加工は、外観と機能性の両方において、最終製品に酷似したエンジニアリングまたは生産プロトタイプを作成するのに最適です。Yicenでは、即座の見積もりと迅速な配達を提供し、お客様のニーズに合った正確で高品質のCNC機械加工プロトタイプを提供します。

- リードタイム:1-5営業日

- 能力:1~100個

- 20%割引

少量生産のCNCマシニングは、多くの場合、新しい生産と新興の生産のためのプロトタイピングと大量生産の間のブリッジとして機能します。Yicenを使用することで、このプロセスがより簡単に、より効率的に、そしてコスト効率よくなり、高品質な基準を維持しながら迅速に生産を拡大することができます。

- リードタイム:5-15営業日

- 能力:101~10,000個

- 厳しい仕様を満たす

CNC生産加工は、1000個以上の部品を効率的に生産するための最適なソリューションです。多様な素材と自動化・多軸化機能を活用し、厳しい公差、優れた寸法精度、高い信頼性、迅速な納期で大量生産を実現します。

- リードタイム:2~4週間

- 能力10,001個以上

- 一貫した品質

よくある質問

CNC旋盤加工

What file formats do you accept?

We accept all standard CAD and engineering formats used in CNC machining:

- STEP (.step / .stp)

- IGES (.igs / .iges)

- Parasolid (.x_t / .x_b)

- SolidWorks (.sldprt)

- DXF / DWG for 2D drawings

- PDF for dimensioned technical drawings

Providing a technical drawing with GD&T improves accuracy, especially for parts needing precision CNC turning.

What materials can be turned?

We machine a wide range of metals and engineering plastics commonly used in precision CNC turning. Metals include aluminum (6061, 7075), stainless steel (304, 316, 17-4), carbon steels, brass, copper, titanium, and high-temperature alloys such as Inconel. Plastics such as POM, Nylon, PEEK, PTFE, PVC, and ABS are also supported for custom CNC turned parts. Material selection is validated based on machinability, dimensional stability, and final application requirements.

What tolerances can you achieve?

Typical CNC turning tolerances are ±0.005″, while tight-tolerance CNC turning services can achieve ±0.001″ or better on critical diameters, shoulders, and mating surfaces. Roundness can be controlled to ≤ 0.002″, with concentricity typically held within ≤ 0.005″ depending on geometry and tool access. All tolerance requirements are confirmed during DFM review to ensure the design is manufacturable.

Do you offer live tooling?

Yes. Our CNC turning services include live tooling and multi-axis turning, enabling milling, drilling, slotting, and threading operations within a single setup. This improves concentricity, reduces tool changes, minimizes fixture requirements, and shortens lead time — especially for complex turned-milled components.

What surface finishes do you offer?

We provide a full range of finishing options for metal and plastic turned parts:

- As-turned

- ビーズブラスト

- パウダーコーティング

- Anodizing (Type II / Type III)

- Polishing / Electropolishing

- ブラックオキサイド

- Zinc & nickel plating

Finishes are selected based on durability, corrosion resistance, friction behavior, or cosmetic needs. Surface roughness can reach Ra 0.8 μm for high-precision turning applications.

コンセプトを精密部品に変える

私たちは、お客様のアイデアを比類のないスピードと精度で、高品質で機能的な部品に変換することを専門としています。高度な技術と熟練した職人技で、最も複雑な仕様を満たす部品を作り出します。

- エンド・ツー・エンドの精密エンジニアリング

- 生産ワークフローの合理化

- 卓越した加工への取り組み

- 信頼できる納期厳守

- すべてのアップロードは安全かつ機密です。