A. What Are Surgical Instruments and Tools?

Surgical instruments and tools are precision medical devices designed for performing specific functions during surgical procedures, diagnostic examinations, and patient care. These critical instruments include scalpels, forceps, clamps, retractors, scissors, needle holders, and specialized orthopedic or neurosurgical tools. Used across hospitals, surgical centers, dental practices, and veterinary clinics, these instruments must deliver consistent performance in sterile environments. The precision CNC machining of surgical instruments ensures dimensional accuracy, smooth edges, and surface finishes that enable proper sterilization while maintaining functional integrity throughout thousands of use cycles.

B.主な技術要件

Surgical instruments CNC machining requires exceptional tolerances of ±0.0005″ to ±0.001″ to ensure proper fit, alignment, and functionality during critical procedures. Material specifications mandate biocompatible, corrosion-resistant alloys that withstand repeated sterilization cycles—typically 316L stainless steel, 17-4 PH stainless, or titanium alloys. Surface finish requirements range from Ra 8-32 microinch for contact surfaces to mirror polishes (Ra <4 microinch) for cutting edges, preventing tissue adhesion and bacterial colonation. Instruments must maintain mechanical properties under autoclave sterilization (121-134°C), chemical exposure, and physical stress during use. Edge sharpness, jaw alignment, and spring tension require precise manufacturing to ensure surgeon confidence and patient safety during every procedure.

C.製造上の課題と解決策

Machining surgical instruments presents unique challenges including maintaining razor-sharp cutting edges without burrs, achieving mirror-finish surfaces on complex geometries, and preventing work-hardening of stainless steel alloys during fabrication. Thin-walled sections, intricate jaw patterns, and micro-features require specialized tooling and programming strategies to avoid deflection or breakage. Yicen Precision overcomes these challenges through advanced 5-axis CNC machining that maintains consistent tool engagement, high-speed spindles with precision collets for micro-tooling, and proprietary CAM strategies optimized for medical-grade materials.

Our quality control measures include CMM inspection for dimensional verification, surface roughness testing, and optical measurement for edge geometry. We employ specialized grinding and polishing processes to achieve medical-grade surface finishes while maintaining tight tolerances. Material certifications, lot traceability, and process validation documentation ensure every surgical instrument meets regulatory requirements. Contact us for technical consultation on your surgical instrument manufacturing needs.

D.アプリケーションとユースケース

Precision-machined surgical instruments serve critical functions across multiple medical specialties:

- General Surgery: Scalpel handles, surgical scissors, needle holders, and tissue forceps for standard surgical procedures

- Orthopedic Surgery: Bone saws, reamers, drill guides, plate benders, and joint replacement instrumentation

- Cardiovascular Surgery: Vascular clamps, retractors, micro-scissors, and specialized cardiac instruments

- Neurosurgery: Brain retractors, micro-forceps, cranial drills, and precision cutting tools

- Dental Surgery: Extraction forceps, elevators, scalers, and implant placement instruments

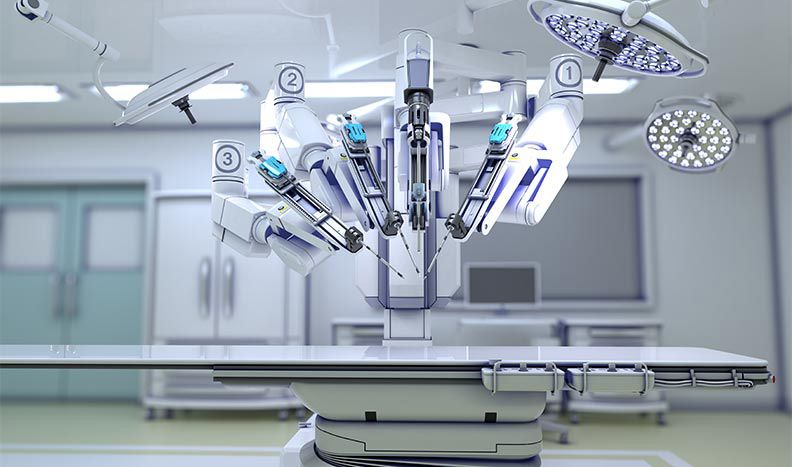

- Minimally Invasive Surgery: Laparoscopic graspers, arthroscopic shavers, and endoscopic tools

- Veterinary Medicine: Animal-specific surgical instruments and diagnostic tools

E. Why Choose Yicen Precision for Surgical Instruments and Tools?

Yicen Precision brings specialized expertise in medical device manufacturing with ISO 13485 certification and comprehensive regulatory knowledge. Our surgical instruments CNC machining services deliver rapid prototyping with 3-5 day turnarounds for sample instruments, enabling faster design validation and market entry. We offer scalable production from prototype quantities to high-volume manufacturing runs, maintaining consistent quality through statistical process control.

Our engineering team provides Design for Manufacturability (DFM) consultation to optimize instrument designs for production efficiency and performance. Complete material traceability includes mill certifications, biocompatibility documentation, and batch tracking for regulatory compliance. We maintain cost-effective solutions through optimized toolpaths, efficient material utilization, and streamlined inspection processes—delivering medical-grade surgical instruments without premium pricing. Request your custom quote today for precision surgical instruments that surgeons trust.